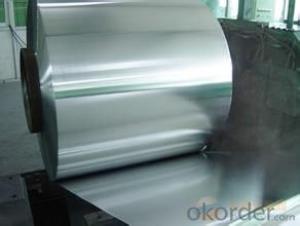

cold rolled steel coil / sheet / plateSPCE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

The raw material of cold rolled steel coil/sheet is high quality hot rolled product, and after pickling, kinds of new technology and new process of global cold rolling production have been applied. Therefore the manufacturing, home appliance, automobile etc.

Specification:

COLD ROLLED STEEL | |

Thicknenss | 0.10mm-4.00mm |

Width | 600mm-2000mm |

Sheets length | 1200-6000mm |

Coil inner diameter | 508-610mm |

Surface treatement | matt finish/bright finish,oiling/dry, bright anneal/black anneal |

Coil weight | 3-5t |

Application:

1. Refrigerators, cabinets, power distribution baords and drums.

2. Automobile floor and roof panels.

3. Automobile fenders and quarter panels

4. Automobile fenders and quarter panels

Images:

Our products enjoy an excellent reputation and have been exported to Europe, South-America, the Middle-East, Southeast-Asia, Africa and Russia etc.. We sincerely hope to establish good and long-term business relationship with your esteemed company.

FAQ

1. Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.for quality inspection every day.

- Q: How are steel coils used in the production of construction machinery?

- Steel coils are used in the production of construction machinery as they provide the necessary strength and durability required for heavy-duty equipment. These coils are shaped and formed into various components such as frames, chassis, and structural parts, ensuring the machinery can withstand the rigorous demands of construction sites. The versatility and malleability of steel coils allow manufacturers to create complex and intricate designs, resulting in reliable and robust construction machinery.

- Q: Can cold rolled galvanized steel coils be acid washed after oxidation?

- Rolling at room temperature is generally understood as cold rolling, from a metallurgical point of view, below the rolling temperature at which the roll is rolled

- Q: Explain how you could make plastic sink and steel float?

- you can use the steel to make a hollow box, or a ship. There are thousands of steel ships floating in the oceans. plastic, specific gravity ranges from 0.6 to 2, so the higher density ones will sink. Here are some that will sink: Nylon (Polyamide) 1.15 g/mL Plexiglass (Polymethylmethacrylate or PMMA) 1.19 g/mL Lexan (Polycarbonate) 1.2 g/mL PVC (Polyvinyl chloride) 1.16-1.38 g/mL PETE (Polyethylene terephthalate) 1.38-1.39 g/mL .

- Q: How are steel coils used in the production of HVAC systems?

- Steel coils are used in the production of HVAC systems as they serve as the primary component for heat transfer. These coils are responsible for absorbing heat from the surrounding air and transferring it to cool the interior of a building. Additionally, steel coils are used for the condenser coils in HVAC systems, where they aid in the removal of heat from the refrigerant, allowing for efficient cooling and dehumidification.

- Q: Why are properties of steel not identical?

- Grade 440C is one of the highest strength stainless steels. It is also very wear resistant. Good for use as ball bearings and other high wear applications. 400C has the highest carbon content of the 440 steels. 440A and 440B are identical but have lower carbon contents and have lower strengths and higher corrosion.

- Q: Can steel coils be coated with magnetically attractive materials?

- Yes, steel coils can be coated with magnetically attractive materials. This process is commonly known as electromagnetic coating or magnetic coating, where a thin layer of magnetically attractive material, such as iron or nickel, is applied onto the surface of the steel coil. This coating enhances the magnetic properties of the steel, making it more responsive to magnetic fields and enabling it to attract or be attracted by magnets.

- Q: I saw a 27 sedan and a 27 Pick-up one had wood wheels the other steel, respectively. Witch one was original or were they both original

- Wooden Spoke Wheels

- Q: How are steel coils inspected for straightness?

- Steel coils are inspected for straightness through a variety of methods to ensure they meet the required quality standards. One common method is visual inspection, where trained inspectors visually examine the coil for any visible defects or deformations that may indicate a lack of straightness. They carefully observe the coil's edges, surface, and overall shape to identify any irregularities. Another method used is measuring the coil's straightness using precision instruments. This involves taking measurements at various points along the coil's length and comparing them against specified tolerances. Techniques such as laser measurements or straightness gauges are employed to accurately assess the deviation from the desired straightness. Furthermore, some coils undergo non-destructive testing, such as magnetic particle inspection or ultrasonic testing, to identify any internal defects or stresses that could affect the straightness. These tests can reveal hidden flaws that may not be evident through visual inspection alone. In addition, some manufacturers may employ automated inspection systems that utilize advanced technologies like computer vision or artificial intelligence. These systems can quickly scan the coil's surface and analyze it for any deviations from straightness, providing precise measurements and ensuring consistent quality. Overall, the inspection of steel coils for straightness involves a combination of visual inspection, precise measurements, non-destructive testing, and advanced technologies. These methods aim to identify any deviations from the required straightness, ensuring that only coils meeting the specified standards are used in various applications.

- Q: What are the dimensions of steel coils used in the oil and gas industry?

- The dimensions of steel coils used in the oil and gas industry vary depending on the specific application and requirements. However, common dimensions for steel coils in this industry typically range from 0.5mm to 3mm in thickness and 600mm to 2000mm in width. The length of the coils can vary, but they are often around 2000mm to 6000mm.

- Q: What are the different coil cutting machine options available for steel coils?

- Steel coils can be cut using various machines, each designed to meet different needs and specifications. The available options are as follows: 1. Slitting Machine: This machine slices large steel coils into narrower strips or slits. It incorporates a circular blade that moves across the coil's width, cutting it into desired widths. Industries like automotive, construction, and manufacturing commonly use slitting machines due to their ability to handle a wide range of steel coil thicknesses. 2. Cut-to-Length Machine: This machine is used to cut steel coils into specific lengths. Equipped with a shearing mechanism, it cuts the coil based on programmed length requirements. Cut-to-length machines are particularly beneficial when precise and consistent lengths are necessary, for instance, in the production of steel sheets or plates. 3. Rotary Shear Machine: Designed to cut steel coils into smaller pieces or squares, this machine employs a rotating drum with multiple cutting blades. It shears the coil in a continuous process, making it suitable for industries that require smaller steel pieces for further processing or assembly. 4. Guillotine Shear Machine: Equipped with a vertically moving large blade, this machine is used for high-speed and high-precision cutting of steel coils. It is commonly employed in heavy-duty industries like shipbuilding and metal fabrication, as it can handle thicker steel coils. 5. Laser Cutting Machine: Laser cutting machines provide a highly precise and versatile method for cutting steel coils. By using a focused laser beam to melt or vaporize the material, they ensure clean and accurate cuts. Laser cutting machines are suitable for a wide range of steel coil thicknesses and can handle complex shapes and patterns. These examples illustrate the available options for cutting steel coils. The choice of machine depends on factors such as coil thickness, required cutting precision, desired output volume, and specific application requirements.

Send your message to us

cold rolled steel coil / sheet / plateSPCE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords