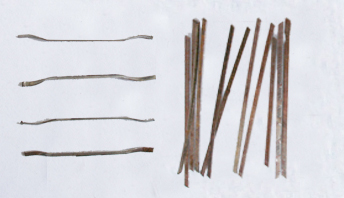

Cold Lace-off stainless steel fibers

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cold Lace-off stainless steel fibers

Cut from high quality stainless steel wire is mainly used for refractory castable, it has superior tensile strength and flexibility.

Product function:

A, enhanced fire resistance of refractories

B, extend the life of refractories and endurance

C, reduce downtime and maintenance costs

Product specifications and models:

Chemical Composition melting range Diameter (mm) Tensile strength (MPa)

Cr Ni maximum average

304 18-20 8-10 2550-2650 1800 0.4-1.0 ± 0.02 ≥1200

31024-2619-22 2550-26502100

Application:

Used in refractory enhancement industry, such as oil, steel, chemicals, cement.

- Q: How do steel products contribute to sustainable development?

- Steel products contribute to sustainable development in several ways. Firstly, steel is a highly recyclable material, which reduces the need for mining and extraction of new raw materials. This helps conserve natural resources and reduces the environmental impact of steel production. Additionally, steel has excellent durability and strength, leading to long product lifecycles and reducing the frequency of replacements. This not only saves resources but also reduces waste generation. Furthermore, steel is widely used in construction and infrastructure projects, contributing to the development of sustainable and resilient cities. Its ability to withstand extreme weather conditions and seismic events makes it an ideal choice for building structures that are durable, safe, and energy-efficient. Overall, steel products play a crucial role in promoting sustainable development by conserving resources, reducing waste, and creating resilient infrastructure.

- Q: How is steel used in the agricultural industry?

- Steel is used in the agricultural industry for various purposes such as constructing structures like barns and storage units, manufacturing equipment like tractors and harvesters, and creating fencing and irrigation systems. Its durability and strength make it a reliable material for supporting the needs of modern farming practices.

- Q: How are steel coils used in manufacturing processes?

- Steel coils are used in manufacturing processes as a primary material for various applications such as construction, automotive, appliances, and machinery. These coils are typically unwound and processed through different machines to be shaped, cut, and formed into the desired products. The versatility and strength of steel coils make them an essential component in many manufacturing industries.

- Q: How is steel wire rope strength tested?

- Steel wire rope strength is typically tested using a method called a tensile test. This involves applying a gradually increasing force to the rope until it breaks, allowing researchers to determine its maximum load capacity and overall strength.

- Q: How are steel products different from iron products?

- Steel products are different from iron products in that steel is an alloy made by combining iron with carbon and other elements, resulting in a stronger, more durable material compared to pure iron. Steel also has a higher melting point, better corrosion resistance, and greater versatility in terms of shapes and sizes that can be manufactured.

- Q: What are the applications and uses of steel products in various industries?

- Steel products have a wide range of applications and uses in various industries. In the construction industry, steel is extensively used for building structures, bridges, and infrastructure due to its strength and durability. It is also commonly used in the automotive industry for manufacturing car bodies and structural components. Additionally, steel is essential in the manufacturing of machinery, tools, and equipment across various sectors. Its versatility and ability to be fabricated into different shapes make it ideal for creating pipes, wires, and electrical appliances. Moreover, steel is widely used in the energy sector for power generation and transmission, as well as in the packaging industry for cans, containers, and packaging materials. Overall, the applications of steel products are vast and crucial in numerous industries due to their strength, versatility, and reliability.

- Q: How is steel used in the manufacturing of packaging materials?

- Steel is commonly used in the manufacturing of packaging materials due to its strength, durability, and versatility. It is often used to create cans, containers, and drums for packaging various goods like food, beverages, and chemicals. Steel packaging provides excellent protection against moisture, light, and contaminants, ensuring the safety and preservation of the packaged products. Additionally, steel is recyclable, making it an eco-friendly choice for packaging materials.

- Q: How is steel tubing used in hydraulic systems?

- Steel tubing is commonly used in hydraulic systems to transport hydraulic fluid under high pressure. It provides a strong and durable channel for the fluid to flow through, ensuring reliable and efficient transmission of power. Additionally, steel tubing's resistance to corrosion and high temperatures makes it ideal for withstanding the harsh conditions often found in hydraulic systems.

- Q: Can steel be used in the production of food-grade equipment?

- Yes, steel can be used in the production of food-grade equipment. Stainless steel, in particular, is commonly used due to its corrosion resistance, durability, and ease of cleaning. It is safe for direct contact with food and meets the hygiene and safety standards required for food production.

- Q: How is steel used in the production of machinery and equipment?

- Steel is widely used in the production of machinery and equipment due to its strength, durability, and versatility. It is used to manufacture various components such as frames, casings, gears, and bearings, providing the necessary structural integrity and mechanical capabilities. Steel's ability to withstand high temperatures, corrosion, and heavy loads makes it ideal for applications in heavy machinery, construction equipment, automotive industry, and many other sectors.

Send your message to us

Cold Lace-off stainless steel fibers

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords