Coated Aluminum Pipes Coil-AA3105

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

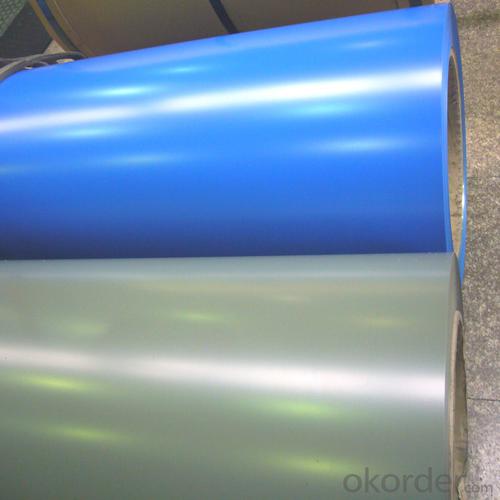

1.General Information of Color Coated Aluminium Coil with Competitive Prices

Aluminum coil is between 0.1 mm and 500mm in thickness and has a wide variety of uses in the construction industry including aluminium siding and roofing. Sheet is also used widely in construction, decoration, transport applications and other various industrial filed, such as automobile body panels, airframes, curtain walls and the hulls of boats etc.

Alloy | AA1050,AA1060, AA1070, AA1100, AA3003, AA3004, AA3005, AA3105, AA5005, AA5052, AA5754, AA5083, AA8011 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-4.0mm |

Width: | 10mm- 2000mm |

Coating | PE(Polyester) |

Painting Thickness | Standard 16-25 microns, max 40 microns |

Color | Acording to Ral colors or customer’s samples |

Standard: | GB/T17748-1999, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

PE(polyester) Coating

PE(polyester) coating:high molecular polymer as monomer and addition of alkyd, is an UV-resistant coating. It can be classified matt and glossy according to coating gloss. The compact molecule structure, makes paint surface luster and smooth,which assure good printing on the panel surface. With an warranty of 8-10 years for weather resistance, it is specially applied for internal decoration and sign board.

2 Usage/Applications of PE Coated Aluminum Coil/Sheet

Our company's PE Coated Aluminum Coil/Sheet have been widely used in the fields of construction and decoration(garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipe, sanwich panels and drainage, etc.

- Q: Do you use seamless pipes or aluminium tubes for cold storage?

- Seamless steel tubes are better than aluminium tubes, and it is recommended to use stainless steel tubes with specifications of 296 or more. The aluminum tubes will be exposed to damp air for 304 years and will oxidize and corrode.

- Q: Air conditioning copper aluminum tube how to connect? It's broken at the copper aluminum pipe joint. What should I do?

- Welding method of freezing evaporator copper aluminum joint1, company introduced Rock ring maintenance technology, on the market if the Rock ring leakage, evaporator leakage or box fault need to change the box, because the factory production and customer service with the Rock Rock ring ring, customer service department has from the German company purchased part of customer service for the rocklyn by Rock ring, but the price is more expensive. Two easy to leak, and must use special crimping pliers.Welding is the welding problems in the process of the Chinese Academy of Sciences, after years of research, developed a new type of welding material, the material can not only be used in copper welding, aluminum welding, more different melting point between the copper and aluminum welding, the result is innovative and advanced, which belongs to the international advanced level. Because the material is the latest achievement in the world, the cost of raw material is more expensive, so the price is higher, and the price will decrease gradually with the decrease of production cost. By calculation, the price of a single solder joint is reduced by 35% compared with the use of a Rock ring.

- Q: How can copper tubes be plated?

- According to the principle of the electrolytic cell, it can be completed! Do this: aluminum cathode of a power supply, a bobbin is connected with the anode, in the aluminum sulfate solution, can be completed! You can check to prevent accidents. Thank you for your attention

- Q: Can aluminum pipes be used for high-pressure applications?

- Yes, aluminum pipes can be used for high-pressure applications. Aluminum is a lightweight, durable, and corrosion-resistant material, making it suitable for various industries and applications, including high-pressure systems. However, the specific pressure rating of an aluminum pipe depends on its size, wall thickness, and alloy composition. It is important to consult industry standards and guidelines, as well as engineering professionals, to ensure that the chosen aluminum pipe is suitable for the intended high-pressure application.

- Q: Can aluminum tubes be oxidized to orange?

- ]TAC, ORANGE-LH (301) is an orange dye used in anodizing of aluminum and its alloys. Chemical properties: metal complexing salts, acid dyes, orange

- Q: Are aluminum pipes suitable for wastewater treatment facilities?

- Indeed, wastewater treatment facilities can make effective use of aluminum pipes. Aluminum, being both durable and resistant to corrosion, proves to be an excellent option for various purposes, including wastewater treatment. Its suitability particularly shines in settings where pipes are exposed to the chemicals and corrosive substances commonly found in wastewater. Moreover, aluminum pipes possess the advantage of being lightweight, making installation and maintenance tasks a breeze. Additionally, due to its impressive strength-to-weight ratio, aluminum can endure substantial pressure and stress without jeopardizing its structural integrity. Consequently, when considering the advantages that aluminum pipes bring to wastewater treatment facilities, they undeniably qualify as a fitting choice for this particular application.

- Q: What are the typical pressure ratings for aluminum pipes for HVAC systems?

- The pressure ratings of aluminum pipes utilized in HVAC systems can differ based on the particular usage and industry norms. Nevertheless, pressure ratings for aluminum pipes in HVAC systems usually span from 150 psi to 500 psi. These ratings guarantee the aluminum pipes' ability to endure the pressure and strain linked with HVAC system operation, encompassing the movement of refrigerants, air, and other fluids. Consulting industry guidelines, manufacturer specifications, and relevant building codes is crucial for determining the suitable pressure ratings for aluminum pipes in HVAC systems.

- Q: Are aluminum pipes suitable for desalination plants?

- Yes, aluminum pipes are suitable for desalination plants. Aluminum is corrosion-resistant, lightweight, and has excellent heat transfer properties, making it an ideal choice for transporting seawater and brine in the desalination process. Additionally, aluminum pipes are cost-effective and have a long lifespan, making them a reliable option for desalination plant infrastructure.

- Q: What is the difference between aluminium pipe and aluminium alloy pipe?

- Aluminum tube refers to a pure aluminum or aluminum alloy by extrusion processing into its longitudinal length of hollow metal tubular material. There may be one or more closed through holes with uniform wall thickness and cross section to be delivered in a straight or coiled form. Widely used in automobiles, ships, aerospace, aviation, electrical appliances, agriculture, machinery and electrical, home and other industries.

- Q: Are aluminum pipes suitable for drinking water applications?

- Yes, aluminum pipes are suitable for drinking water applications. Aluminum is a lightweight, durable, and corrosion-resistant material, making it an excellent choice for piping systems. It is also non-toxic and does not leach any harmful substances into the water. Additionally, aluminum pipes have a smooth surface that minimizes the accumulation of bacteria and impurities. However, it is important to ensure that the aluminum pipes used for drinking water applications comply with relevant industry standards and regulations to guarantee their safety and quality.

Send your message to us

Coated Aluminum Pipes Coil-AA3105

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches