CNC Machine Vertical Machining Center Model 855 1160 with Siemens/Mitsubishi/Fanuc system

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Vertical machining center is a CNC machining machine tool with three coordinate linkage.

It is suitable for processing parts with high accuracy and productivity requirements. Such as drilling, reaming, spot faceing, tapping, milling, boring and other processing can be realized. lt is applicable to small and medium-sized plates,shells, valve bodies, cams and other parts with high hole spacing accuracy.It is applied in industries like mold,automobiles,motorcycles,aerospace,millitary etc.

Spindle rotation maximum speed: 8000—12000 rpm.

The standard configuration is 24 disk tool magazine to meet customer needs.

The head group is a heavy box-type structure with reinforced internal ribs and high rigidity.

The X、Y、Z axis adopts P level roller linear rail, with high rigidity, low noise, can do fast displacement and obtain optimal circulation accuracy.

System option:Siemens / Mitsubishi / Fanuc

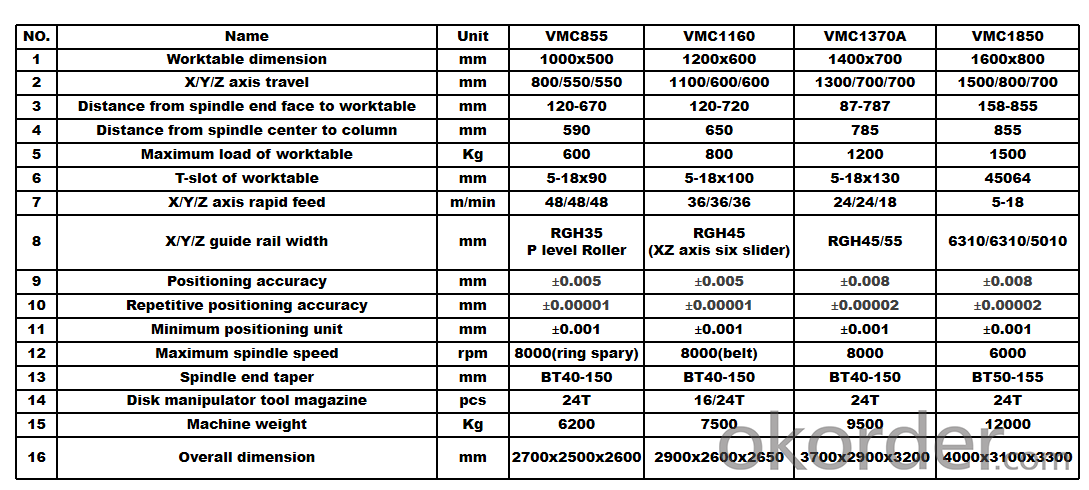

Technical Parameter

Package

Application Area

Suitable for precision machining of large workpieces such as aerospace, automobiles, textile , molds, packaging machinery, mining equipment, etc. It can automatically complete complex machining processes such as boring, drilling, milling, tapping, etc.

Global Sales Market

Cooperative Clients

Q&A

Q1. Where is your factory located?

A : Our factory is located in Taizhou City, Zhejiang Province, China.

Q2. Are you produce peeling/ polishing machine's specific parameters according to the samples?

A: Yes, we produce the machine you want by your samples or technical drawings.

Q3. What is your sample service?

A: We can supply the sample testing which client want to produce if we have ready machine in stock.

Q4. What is your MOQ of your machine?

A: Normally our MOQ is 1 set.

Q5. Do you test all your machine before delivery?

A: Yes, we have 100% test before delivery.

Q6: What is the payment term?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q7: What is the normal lead time?

A: 45-60 days after we receive the deposit.

Q8: Guarantee Period?

A: 1 year. During the guarantee period, we guarantee to solve all problems may occur due to machine's quality or wrong design, and to provide all necessary spare parts for repair. We can send the technician to customer's factory if problem is serious and can't be solved by the customer.

- Q: Processing center models are what? How to classify the various models are on behalf of what does this mean?

- Processing center discrete and lying plus, gantry machining center, CNC boring and milling machining center

- Q: Machining center with an end mill milling side of the surface when the collapse is caused by what causes.

- Machining center with the end mill milling side of the surface should be a shock pattern, the main may be too long tool clamping length, or processing margin is too large, or the accuracy of the tool or spindle, when using the end mill Note the following:

- Q: What does metal processing machinery include?

- Automation equipment: automatic tools, bearings, cleaning machines, mechanical drive systems, automatic control systems, packaging equipment, etc .; casting equipment: stamping equipment, lathes, milling machines, forming machines, finishing machines, drilling machines, special purpose machinery

- Q: Machining center cutting oil has been smoke how to do?

- For general cutting, compared with the commonly used cutting oil, the workpiece surface roughness reduced by 0.5 times the cutting effect increased by 50-100%.

- Q: Processing area of the processing center

- Box type of workpieces such as the general requirements of the workpiece are more than the hole and the plane of the processing, positioning accuracy requirements, processing in the processing center when a fixture to complete the ordinary machine 60% to 95% of the process content.

- Q: Which big god gets advice, cnc processing center g code g28g98g99 in the end what is the meaning. To be detailed. Have labor Thank you

- 91G30Z0 (Z axis back to the library 0 zero, the height of the knife, the point of some machines and machinery 0 points coincide)

- Q: The difference between milling and reverse milling in cnc CNC machining center

- eave the gap on the left; as the screw continues to rotate, the gap back to the right, in this The moment the table to stop the movement; when the horizontal milling force is large to a certain extent, there will be to promote the table and the screw again to the right of the movement.

- Q: How about Cheong Cheong Machining Center

- To see who compared with the Taiwan machine in the calculation of the level, the quality is not comparable to Ouma, Dongtai Seiki and Paterson, the price is not friends Jiajia, the company is not as good as Yongjin and Taichung Seiki, but compared to some small

- Q: Processing center G99 how to use, it is best to use examples, but also what the R value of what it means.

- Point (R1) drill down drill all the holes in turn. After drilling the first hole with G99, the spindle is quickly raised to point R and moved to the next point after the coordinates of the feed under the drill .R point that is the machine in the Z direction

- Q: Machining Center Large Area Aluminum Plane Machining

- Flying thickness in place 2 to stress tongs leveling to ensure flatness 0.1 3 the rest of the milling to pay attention to the protection of the appearance of 4 to clamp workers to ensure flatness of the blank.

Send your message to us

CNC Machine Vertical Machining Center Model 855 1160 with Siemens/Mitsubishi/Fanuc system

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches