300,000m3/year AAC Block Brick/Autoclaved Aerated Concrete Production Line Machinery

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

AAC Block Brick/Autoclaved Aerated Concrete Production Line Machinery (300,000m³/Year)

Product Description:

We produce 4.0m, 4.2m, 4.8m, and 6m series of high capacity AAC production line for Middle East, Africa and South-east of Asia, etc. The entire set of Aerated-Concrete equipment we produce has become universal products for domestic new and existing aerated factories. AAC blocks will become the dominant wall material in future.

Production Process:

1. Stocking and supplying raw materials

2. Processing raw materials

3. Batching and pouring

4. Cutting

5. Grouping and maintaining process

6. Steaming in autoclaves

7. Final product packaging

Product Principle

Technological Orientation

Production and application of aerated concrete has a history more than 40 years in China. Viewed from a technology standpoint, high quality products can use 3mm special sand slurry technology to meet the construction requests and 50% energy saving goals. (When mortar joint is less than 3mm, take thermal conductivity coefficient of wall as 1; when mortar joint is more than 3mm, take thermal conductivity coefficient of wall as 1.5). Based on the history of the aerated concrete development, only high quality products can bring a prosperous market. Thus, the technology is able to produce high-class products according to China Standard GB11968-2006.

Production Capacity

In our factory, the main production capacity is annually 50,000m³, 100,000m³, 150,000m³, 200,000m³, 300,000m³ etc. The product is aerated concrete block which is light in weight. Also, there is a reservation of plate in consideration of users' need.

Production Line Design.

Including: drawing of plant working process, drawings of land construction, drawings of power working, drawings of driving force for working, drawings of anti-dust, drawings of water supply and drainage, and drawing of air pipeline construction.

Technical Guidance of Building Factory

Including: consultation of facility, Equipment installation guide, constitution the production preparation, etc.

Providing the technical information of setting up factory

Including: part of the factory management system, all posts accountability of production line, process rules, safety rules, setting a quota of staff and posts, pre-production tools directory, laboratory instruments, product catalogs, and test methods.

Product Features:

· Simple and practical operation

· Waste materials and water can be recycled during operation process

· Equipment has higher degree of automation

· Final products have a production rate of ≥ 98%

· Good cost performance

· German design

· Products conform to requirement of 04~07 grade blocks stated in GB11968-2006

Product Applications:

Product Specifications:

Capacity: 100,000m³-300,000m³

Full or Semi automation

High quality

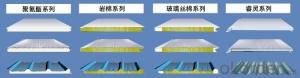

Product Images:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

- Q: What are the shortcomings of traditional machining?

- Low efficiency, high cost, batch processing, then the processing quality is not stable, the accuracy is not high, labor intensity, processing staff, frequent processing times, and now good equipment to complete the car, drilling, milling and other processes.

- Q: Information on building materials decoration.

- Equipment Construction Projects Cooperation Adhesives Metal Building Materials Insulation Materials Building Materials Door and Window Wall Materials Wood Sheet Other Building Materials Products Construction Materials Stone Stone Lime, Gypsum Plastic Building Materials Locks Ceramic Processing Machinery

- Q: Information on building materials decoration.

- products special building materials ceiling paint culture stone processing machinery brick, tile and block decoration building materials agent operating reference:

- Q: Classification and components of hydraulic press

- according to the size of the equipment according to the size of equipment, hydraulic equipment can be divided into large equipment, medium-sized equipment, small equipment.

- Q: Mechanical processing technology to mechanical product design, specifically to prepare what?

- In short, all aspects of knowledge are learning, and now the design is basically simplistic, and many things have been modular, and said white, the design is used when the experience, a long time you naturally understand.

- Q: Main classification of hydraulic machinery?

- (5) According to the application of equipment, hydraulic equipment can be divided into many types, such as machine tool hydraulic equipment, plastic molding processing hydraulic equipment, engineering machinery hydraulic equipment, steel metallurgy hydraulic equipment, building materials processing hydraulic equipment.

- Q: What gear is machined out of the gear?

- The bevel gears are laid on the planer. Spiral bevel gears - forming end mills.

- Q: What is the principle of the cutting order in machining?

- That is, the first should be used as a refined reference surface, and then processed to the basis of precision positioning for the processing of other surfaces.

- Q: What are the aspects of the mechanical processing quality

- Mechanical processing, machine tools, fixtures, knives and workpieces constitute a complete system, known as the process system. The machining error is due to the fact that there are many error factors in the process system before and after processing, collectively referred to as the original error. The original error of the process system mainly includes:

- Q: What are the oyster processing companies?

- printed posters printing desk calendar printing calendars printing business cards printing envelopes printing paper printing stickers printing other commercial printing processing books printing processing paper processing 2 processing laser plus .. The

Send your message to us

300,000m3/year AAC Block Brick/Autoclaved Aerated Concrete Production Line Machinery

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords