Automatic metal steel sheet plate cnc bending machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 SET

- Supply Capability:

- 10000 SET/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

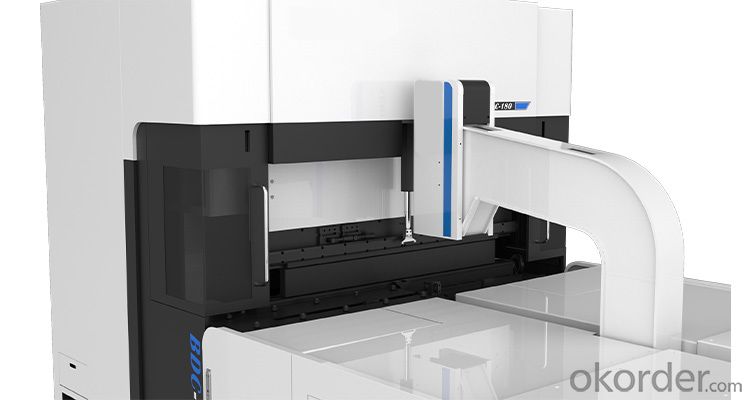

The servo control metal bending machine is an equipment for processing thin plates. Its structure mainly includes a tool holder, worktable, a clamping feeding device and a CNC operating table. The worktable is composed of a base and a clamping piece feeding structure. The workpiece is positioned and clamped on the worktable and delivered to the processing position through the feeding mechanism, and the bending tool is driven by the tool holder to process the workpiece.

The machine body processing by high precision temperature control tempering furnace to completely release the internal stress of welding, ensure it will not easy to deform and the stability of the equipment. The full servo control system can ensure more stable feeding. The bending tool can complete the shape of non-right angle, right angle, circular arc, pressing dead edge, etc

Parameter

Model | BDC-180 |

Bending Length | 1800mm/70.86inches |

Bending Maximum Thickness | 3mm |

Maximum Bending Height | 170mm/6.69inches |

Minimum Bending Height | 6mm/0.23inches |

Minimum Molding Size of Four Sides | 260mm*260mm |

Minimum Size of Unilateral Molding | 160mm |

Minimum Arc Radius | 1.2mm |

Minimum Continuous Bending Speed | 0.2S |

Bending Angle | 0-180 |

Maximum Feeding Speed | 120m/min |

Outline size(mm) | 5000*2600*2900 |

Total Power | 75KW |

Workbench Structure | Mainly with brushes |

Quantity of Axis | 13-axis concurrent linkage |

Higher Bending Accuracy

Fully Automatic and More Intelligent

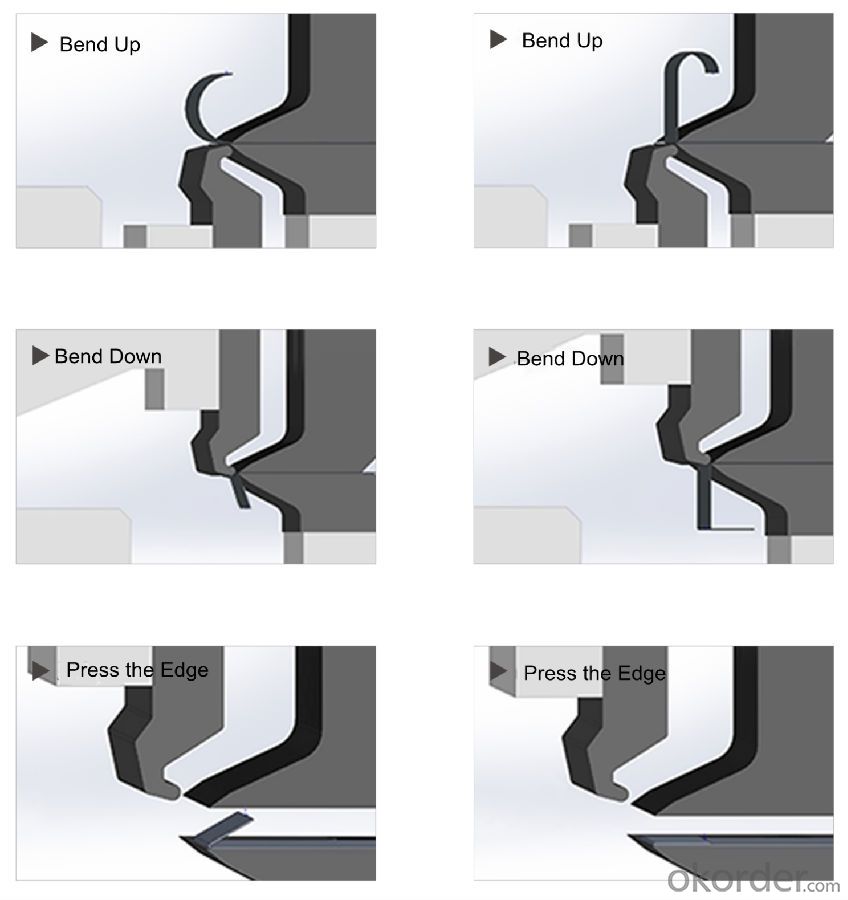

Various Bending Shapes

The bending tool can complete the shape of non-right angle, right angle, circular arc, pressing dead edge, etc.

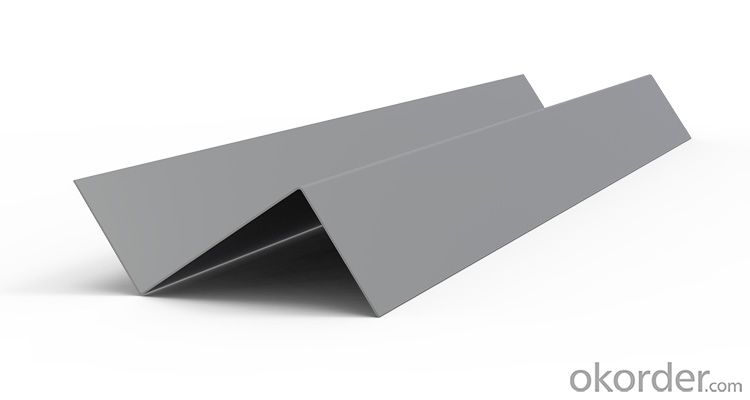

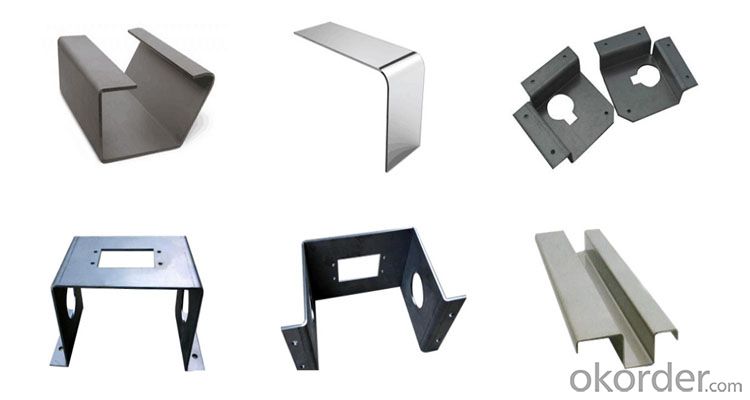

Samples Show

This bending machine is a high-tech product developed and produced for the sheet metal industry to improve productivity, reduce the labor intensity of operators, improve product quality, widely used in refrigeration, medical treatment, building materials, kitchen utensils, environmental protection, wind turbines and other industries.

Steel | Maximum Thickness |

Carbon steel(mm) | 1.5 |

Stainless steel(mm) | 1.2 |

Aluminum (mm) | 2.5 |

- Q: Which industries need laser equipment?

- Laser marking technology can be used in industry such as marking, welding, cutting, surface heat treatment and internal crystal carving.

- Q: Is the sale of laser equipment good?

- direct equipment sold to demand manufacturers, individual equipment can also recruit agents.

- Q: What are the manufacturers of laser welding equipment?

- Then most of them will soon run away.

- Q: What are the laser hair removal equipment?

- At present, most high-end optical equipment brand agent is America Lumenis and Israel feidun company. The two companies brand in the industry are very

- Q: Sales channels for laser equipment?

- Run a few large energy and technology companies, and be familiar with communicating their purchases!

- Q: Excuse me, how can you install the laser tube of the laser equipment?

- When the first oxide layer of the anode and the cathode terminal of the 3. terminal polished off the laser tube, and then use the metal thin copper wire two wiring column wrapped on the tin, then tin anode wire butt welding laser tube. Requirements: no burr. The laser tube anode terminal by silica gel seal 705 and all the lines, water pipes can be fixed in order.

- Q: How much is the cutting thickness of laser cutting machine?

- This is because the laser cutting cutting width is narrow, generally between 0.1 to 0.5mm; the cutting precision is very high, and the error is less than 0.05mm, from the centre of the hole between 0.1 and 0.4mm, the error profile size between 0.1 to 0.5mm; the cutting section incision smooth, roughness of less than 25 m, after the completion of the workpiece cutting then, without processing, can be directly welded.

- Q: What should be used in laser welding equipment?

- to heat the area of small products. (ie a fine line)

- Q: Principle of laser rust removal

- A) the beam emitted by the laser is absorbed by the contaminated layer on the surface to be processed.

- Q: What are the main industries for laser equipment?

- China's laser industry market foresight and investment strategy planning analysis report in 2015-2020

Send your message to us

Automatic metal steel sheet plate cnc bending machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 SET

- Supply Capability:

- 10000 SET/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords