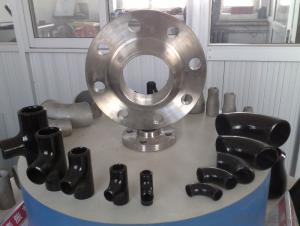

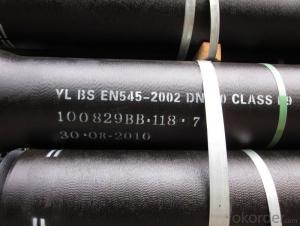

CNBM ISO2531/EN545 DI PIPE & FITTINGS,HIGH QUATITY

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Ductile Iron pipe Fittings:

1.Material Iron ,made in China

2.Technics Casting

3.Model Number DN80-DN2000

4.Brand Name CMAX

CNBM manufactures Ductile Iron Push-on Joint & Mechanical Joint Fittings which conform to Product standards: EN 545:2002, ISO-2531:1998, ANSI/AWWA C153/C110 & GB13295. The fittings are made with the most modern casting technique known as Vacuum Lost Foam Process.

Ductile Iron fittings without branches conform to class-K12. Ductile Iron fittings with branches conform to class-K14. For calculating thickness e= K(0.5 + 0.00IDN).

Some Fabricated Fittings are also available from us

1. Composition of raw material:

l C: 3.4 - 3.7%

l Si: 2.0 - 2.4%

l P: ≤0.08%

l S: ≤0.015%

l Mg: 0.03 - 0.08%

l Mn: ≤0.30%

Average Density of Metal is approximate 7050kg/m

2. Mechanical Properties of ductile iron pipe fittings

Item | Tensile Strength N/mm2 | Elongation % | Proof Stress N/mm2 | Hardness HB | ||

DN80 to DN2000 | DN80 to DN1000 | DN1100 to DN2000 | DN80 to DN1000 | DN1100 to DN2000 | ||

Fittings | ≥420 | ≥5 | ≥300 | ≤230 | ||

3. Works Test Pressure of ductile iron pipe fittings

DN | Minimum hydraulic test pressure (bar) |

Fittings | |

60 to 300 | 25 |

350 to 600 | 16 |

700 to 1000 | 10 |

1100 to 2000 | 10 |

5. Internal Lining

Fittings | |

Standard Coatings | Cement mortar |

Reinforced protections | Epoxy Resin/Epoxy Powder |

Special coatings | Please consult us |

6. External Coatings

Fittings | |

Standard Coatings | Basic protection |

Zinc rich paint + Bituminous paint | |

Reinforced protections | Basic protection + |

Epoxy Resin/Epoxy Powder | |

Special coatings | Please consult us |

- Q: How is steel pipe threaded for plumbing applications?

- Steel pipe is threaded for plumbing applications using a threading machine or a manual pipe threader. The pipe is clamped securely, and a die is used to cut threads into the pipe's surface. The process ensures a tight and secure connection between pipes, allowing for leak-free plumbing systems.

- Q: What are the uses of steel wire mesh in agriculture?

- Steel wire mesh has several uses in agriculture. It is commonly used as fencing to protect crops and livestock from external threats such as animals or trespassers. Additionally, steel wire mesh is used as a trellis system for supporting climbing plants like tomatoes, beans, or grapes, ensuring their proper growth and maximizing yield. It can also be utilized as a protective covering for fruit trees or vegetable beds, preventing damage caused by birds or insects. Overall, steel wire mesh is a versatile tool that aids in securing and enhancing agricultural practices.

- Q: How is steel wire galvanized for fencing applications?

- Steel wire is galvanized for fencing applications by immersing it in a bath of molten zinc. This process, known as hot-dip galvanizing, creates a protective coating on the wire. The wire is first cleaned to remove any impurities, then dipped into the zinc bath, ensuring complete coverage. The zinc coating prevents corrosion and extends the lifespan of the wire, making it suitable for fencing applications.

- Q: How are steel products used in the construction of airports and terminals?

- Steel products are extensively used in the construction of airports and terminals due to their strength, durability, and versatility. Steel is used for structural frameworks, such as beams and columns, providing the necessary support and stability for large-scale airport buildings and terminals. It is also used for roofing systems, hangars, and canopies, ensuring protection from the elements and creating functional spaces. Additionally, steel is commonly employed in the construction of runways, aprons, and taxiways, as it can withstand heavy loads and provide a smooth surface for aircraft operations. Overall, steel products play a crucial role in the construction of airports and terminals, contributing to their safety, efficiency, and long-lasting performance.

- Q: What are the common uses of steel in the food processing industry?

- Steel is commonly used in the food processing industry for various purposes, including the construction of machinery and equipment, storage tanks, and food preparation surfaces. It is preferred due to its strength, durability, and resistance to corrosion, making it ideal for ensuring food safety and maintaining hygiene standards.

- Q: What are the properties of carbon steel for industrial use?

- Carbon steel is a type of steel that primarily consists of iron and carbon, with small amounts of other elements. It possesses several properties that make it highly suitable for industrial use. Firstly, carbon steel is known for its exceptional strength and durability, making it capable of withstanding heavy loads and high temperatures. It is also highly malleable and can be easily shaped into various forms, making it versatile for different industrial applications. Additionally, carbon steel exhibits good thermal and electrical conductivity, allowing it to efficiently transfer heat and electricity. Moreover, it has excellent corrosion resistance when properly coated or treated, making it suitable for use in harsh environments. Lastly, carbon steel is relatively cost-effective and readily available, making it a popular choice in various industries such as construction, manufacturing, and transportation.

- Q: What are the different types of steel sheet and plate materials?

- There are various types of steel sheet and plate materials, including carbon steel, stainless steel, alloy steel, and tool steel. Each type has its unique properties and characteristics, making them suitable for different applications and industries.

- Q: What are the properties of weather-resistant steel?

- Weather-resistant steel, also known as corten steel, possesses several properties that make it ideal for withstanding harsh weather conditions. Firstly, it forms a protective oxide layer on its surface, which acts as a barrier against corrosion and prevents the steel from rusting. Additionally, this steel has high tensile strength, allowing it to withstand strong winds and impacts. It also has good weldability, making it easy to fabricate and work with. Moreover, weather-resistant steel is durable and requires minimal maintenance, making it a cost-effective choice for outdoor structures and buildings.

- Q: How are steel products used in the manufacturing of machinery?

- Steel products are used extensively in the manufacturing of machinery due to their strength, durability, and versatility. They are commonly used to construct machine frames, gears, shafts, and other components that require high strength and resistance to wear and tear. Additionally, steel is often utilized in the manufacturing of molds and dies, which are essential for shaping and forming various machine parts.

- Q: What are the different types of steel products used in the manufacturing of packaging materials?

- There are several different types of steel products used in the manufacturing of packaging materials. Some common examples include steel strapping, steel drums, steel cans, and steel sheets. These steel products provide durability and strength to packaging materials, making them suitable for various industries such as food and beverage, pharmaceuticals, and shipping.

Send your message to us

CNBM ISO2531/EN545 DI PIPE & FITTINGS,HIGH QUATITY

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords