CMAX Profile,Pipe, WPC Series Special Use Strong Crusher

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1.can solve the problem of width of sheet,platesand foam coil materical.

2.this serice add a set of haul-off device,two sets of press roller,air press controller.

3.the line speed can reach 30m/min

4.capacity is higher

5.main axis is processed with high quality steel after verifying the balance.

6.the rotor adopts 'V''type cutting technology

7.the CMAX-FP adopts box water cooling system,which avoid sticking the blade because of the heating of materical.

8.we can provide material collection device and powder separation system according to customer's requirements

Specifications

Certification: CE SGS,ISO9001,UL,TUV

1.High capacity

2.Good quality and reasonable price

Our Services

1) Presale service: Freely provide project designing, process designing, choosing suitable equipment for you.

2) Mediumsales service: Accompany you to complete the acceptance of the equipment,draft the construction scheme and detailed process, and complete process of export

3) Aftersales service: We sent engineer to the scene to guide installation, debugging and training operators.

4) we provide engineers available to service machinery overseas

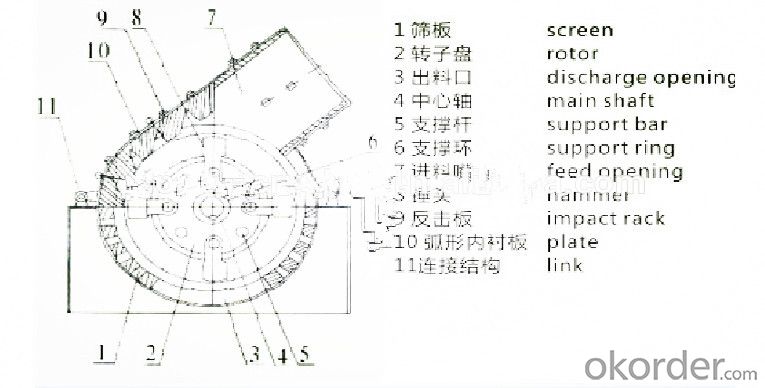

product show

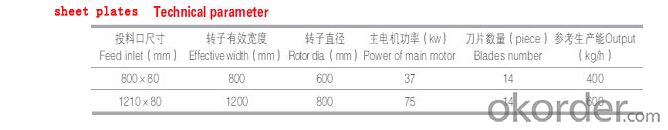

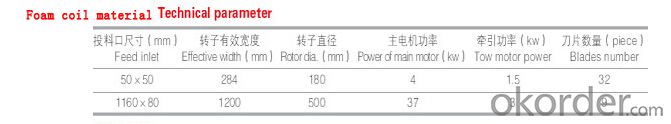

technical data

sheet plates technical

foam coil materical

FAQ:

*Q: What’s the price of this machine please?

*A: Dear customer, for each kind of our machines, we have lots of models.

Generally speaking, we design the production lines according to

different requirements of different machines from different customers.

Therefore, the prices are different. So please kindly inform us your requirements.

For example, the raw material, the output product size, capacity and etc.

The more detailed, the better. Our Engineers will design a suitable production line for you.

- Q: Plastic crusher blade easily broken, because what?

- Third, heat treatment of hardness control, and proper tempering treatment.

- Q: What is the noise produced by a plastic crusher?

- Low noise, mainly used for all kinds of thick wall plastic industry waste material, recycling scrap pieces, the thick and tough, large material (large head materials, large plastic pipe fittings, large diameter thick wall PE pipe, plastic packaging barrels, large bundles of plastic film,

- Q: How to calculate the crushing capacity of a coal crusher?What's the formula?

- What are the main factors that affect the work of the jaw crusher?Generally, the main factors affecting the operation of jaw crusher are meshing angle and RevolutionIs the angle between the meshing angle of moving jaw and fixed jaw. According to the 32 degree calculation of the maximum meshing angle up. The actual use are less than 25 degrees, generally 1820 degrees. The meshing angle is too large, would break up the ore out of the cavity, sand production line, resulting in injury or damage to other equipment. At the same time as the meshing angle increases (crushing ratio increase) decreased productivity. Adjust the size of the mouth of discharge, will change the size of the nip angle. In real life, to adjust the size of the mouth of discharge according to the ore granularity requirements. Therefore, to ensure product size requirements, as far as possible amplification of discharge mouth is reasonable. Gape size can be adjusted by adjusting the block, on the relation between the regulation of discharge should pay attention to broken mouth size ratio and productivity.

- Q: How do you make plastics into particles?

- Then, the plastic granule is obtained by heating, melting and granulating through the plastic extruder.

- Q: How to operate a plastic crusher correctly?

- Ji made machinery for you to answer your questions.I wish you a happy life!!

- Q: Plastic crusher does not eat what is the reason?

- You can check the rotation direction of the rotor is correct.

- Q: How many categories are there in the cutter type of plastic crushers?

- 1 、 all steel welded frame, durable2, easy disassembly design, easy cleaning and maintenance3 、 imported steel cutting tools, sharp blade, easy to change, durable4, grinding all kinds of soft and hard plastic, easy and easy5. It is equipped with motor winding and interlock protection system to ensure safe use6. The minicomputer is equipped with pulleys for easy movement. The large machine has a water cooling system for easy time operation7, you can choose different tools and different hole through the screenClaw knife plastic crusher is suitable for all kinds of plastic pieces of recycle, especially for all kinds of rigid plastic (such as material, shoe material) better.Flat knife plastic crusher

- Q: How should the plastic crusher blade be ground?

- At this time, do not want to quickly disposable grinding good; should be sub polished

- Q: Packing belt above hasp can't get rid of buy a crusher can I directly broken is broken belt

- In the recycling process of waste plastics, waste a lot of it contains a lot of iron

- Q: How often does the plastic crusher get rid of the knife?

- After the machine is used for a period of time, the screw is often removed, it may hurt the thread, the pressure plate is not tight, it is recommended to replace the big steel cap screw.

Send your message to us

CMAX Profile,Pipe, WPC Series Special Use Strong Crusher

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches