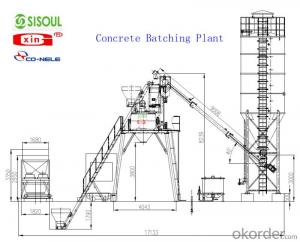

CLS-90 Concrete Mixing Plant

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Capacity: 90 m3/h.

1. Italian SICOMA twin shafts compulsory mixer, with strong mixing ability and high productivity.

2. Dynamic display of the production processes, real time monitoring and control. Various reports can be print out as request.

3. Fully enclosed mixing tower greatly reduces the pollution by dust and noise.

No. | Item | Technical Parameters | Quantity |

1 | Twin shaft mixer | 2×37KW,2m3/batch, Mixing cycle 60s/batch | 1 |

2 | Aggregate belt conveyor | 11kw, 240t/h, B=800 | 1 |

3 | Aggregate elevator | 37KW | 1 |

4 | Cement screw conveyor | φ273, Length=9m, Capacity: 70t/h | 2 |

5 | Aggregate bin | 4X12m3 | 4 |

6 | Aggregate scale | Capacity,4000kg,Accuracy ±2% | 1 |

7 | Cement scale | Capacity 900kg, Accuracy±1% | 1 |

8 | Water scale | Capacity 500kg, Accuracy±1% | 1 |

9 | Coal dust scale(optional) | Capacity 400kg, Accuracy±1% | 1 |

10 | Liquid additive scale | Capacity 50kg, Accuracy±1% | 2 |

11 | Aggregate transition hopper | V=2.5m3,with wearable scaleboard inside | 1 |

12 | Discharge hopper | Discharge height 4m, with wearable scaleboard inside | 1 |

13 | Liquid additive pump | IHG40-160 Q=6.3 m3/h, 2.2KW, 2900rpm | 2 |

14 | Water pump | GSL80-160 H=30m,Q=65m3/h 7.5KW ISG100-100 H=11m, Q=130m3/h,5.5KW | Each 1 |

15 | Water tank | 100~200t, supplied by user, the drawing is provided by seller. | |

16 | Air compressor | Q=1.6m3/min P=1MPa 15kw | 1 |

17 | Gas tank | V=0.5m3 | 1 |

18 | Top dust cleaner | SCM10 Dust collecting area 10m2 1.1KW | 4 |

19 | Mixer dust cleaner | Dust collecting area 10m2 1.1KW | 1 |

20 | Liquid additive storage tank | φ1900; 2 t | 2 |

21 | Control system | Computer control | 1 |

22 | Pneumatic parts | 1 | |

23 | Total installation power | 190KW |

- Q: What is the concrete of the mixing station?

- What else can you do to sell concrete What is the station

- Q: What type of concrete mixer is needed for each hour of concrete 90 cubic meters?

- Many manufacturers will say that the HZS90 station is the one that makes 90 square concrete. In fact, the HZS90 station is supposed to produce 90 square concrete when it is in theory, and it is actually not up to 75 square

- Q: Cement warehouse introduction, storage reserves?

- There's nothing to come, but warm and young About 200 tons

- Q: What is the concept of on-site concrete mixer station

- Concrete mixing station is mainly composed of mixing console, materials weighing system, material conveying system, material storage system and control system of large system and other ancillary facilities. Action: concrete mixing plant is used to concentrate the mixing of concrete, also called concrete precast. Because its mechanization, high degree of automation, productivity is high, and can guarantee the quality of concrete and cement, commonly used in concrete, long duration and site of quantities focus of large and medium-sized water conservancy, electric power, Bridges and other projects. Centralized with the development of municipal construction, stirring, provide commercial concrete mixing station has great advantages, and thus get rapid development, and to promote concrete pumping construction, the mixing, transportation, casting machinery joint operation to create the conditions. Basic introduction: concrete mixing station is mainly composed of mixing console, materials weighing system, material conveying system, material storage system and control system of large system and other ancillary facilities.

- Q: What are the supporting facilities for the concrete mixing stations?

- Concrete mixing equipment, concrete transport equipment, laboratory equipment, forklift, overpound equipment, ground pump, car pump etc.

- Q: How much water does a concrete mixer use every day?

- Water is an indispensable part of the concrete production industry. As an investment company in a concrete mixing station, it is also important to have control over water use. It is also an aspect of production cost control. The use of water used in concrete stations is not the main water link. Flush the blender and cement truck every day to use a lot of water. The concrete is very difficult to handle because of the condensation. So it is the most effluent project in the production standstill. And the washings of these rinsing equipment contain water slurry, aggregates and aggregates, etc. From the environmental point of view, the water of cement mortar or concrete is strong alkaline, the PH value is high, can reach about 12, free discharge can pollute the environment. Therefore, with the continuous improvement of the environmental requirements in recent years, the waste water treatment of the mixing station becomes the main concern.

- Q: What are the facilities of the concrete mixing station

- One. Stir the host The mixing machine is divided into strong mixing and self-falling stirring. The powerful mixer is the mainstream in the domestic and foreign mixers, it can stir the liquid, semi-dry hard and hard and so on. The main mixing liquid concrete of the self-falling mixer is very rarely used in the mixing station. Two. Material transport system The material transport consists of three parts. Aggregate conveying; There are two ways of conveyance and belt conveyance. The advantage of hopper promotion is that the area is small and the structure is simple. The advantage of belt transport is that the transport is large, efficient and low. The belt conveyor mainly applies to the mixing stations that have aggregate storage, thereby increasing the productivity of the mixing stations. Powder conveying; The powder used in concrete is mainly cement, fly ash and mineral powder. The most commonly used powder conveyors are conveyors of screw conveyors, and the large mixing buildings are carried by pneumatic conveyer and scraper. The advantages of screw transport are simple structure, low cost and reliable use. Liquid transport mainly refers to water and liquid admixtures, which are delivered separately by water pumps.

- Q: What are the advantages of HZS series of concrete mixing stations

- Concrete mixing plant is composed of ingredients, mixing and electric control system components made sets of fully automatic concrete mixing equipment, and equipped with a separate manual control, automatic fall compensation, sand moisture content of compensation, can automatically accomplish the tank production. The theory of productivity 75 cubic meters/hour, discharging height is 3.8 meters, the storage hopper volume of 8 cubic * 3 warehouse or 4 warehouse, supporting the host is forced JS1500 type and double shaft mixer

- Q: What is the difference between a concrete mixer and a concrete mixer

- The bone material of the mixing tower is on the top, and the aggregate is measured directly into the mixer. The concrete bin of the commercial concrete station is below, and the bone material is measured and then transported into the mixer after being transported by the inclined belt (which also has some use of the elevator). In a popular way, it is called the building, which is called the second ascent. The steel structure will be larger and the diagonal belt will be relatively longer because of the bone material in the mixing building. But in productivity, the churn is about a fifth higher than the commercial concrete station. In operation, because the inclined belt of the commercial concrete station starts frequently, the energy consumption and the failure rate will increase, and the energy consumption of the mixing building is lower than the failure rate. In the end, because the production capacity of the concrete station is small, the structure is easily disassembled and can be made into a container transfer site, which is suitable for the construction site. The mixing tower is large and high in productivity, and can only be used as a fixed mixer, suitable for the supply of large water projects or large quantities of goods. So customers in the difference between commercial concrete, concrete stand and commodity concrete mixing floor, from aggregate (material), the production efficiency and so on, to choose and buy the right equipment.

- Q: The mixing time of the concrete mixer is in which standard

- Sales missed you do this to see how. If you have any project is continuous uninterrupted production, 24 hours a day, 365 days. As long as there is live, not to stop, of course, is to rest. Want to shift work

Send your message to us

CLS-90 Concrete Mixing Plant

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords