Clear Packaging Tape MSDS - Cloth Tape Synthetic Rubber Adhesive 35micron Various Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

The Cloth Tape is of polyethylene cloth as the carrier, coating with hot melt adhesive, synthetic rubber adhesive or nature rubber. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

The thickness of the tape can be customized.

General purpose of Cloth Tape: widely used for pipe wrapping, gaffers and book binding etc.

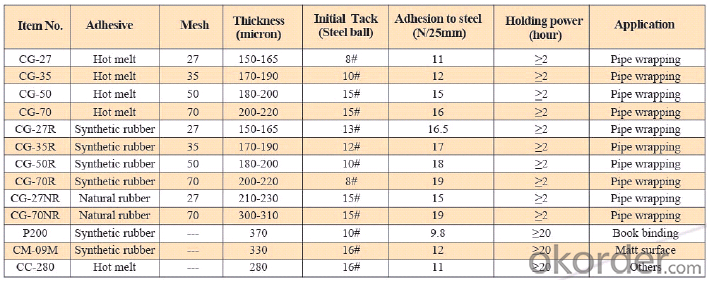

Typical Physical Reports of Cloth Tape

Packaging Detail

The thickness of the tape can be customized.

Log Roll: Length 1000mm; width 1060mm.

Cut Roll: As per customer’s requirements

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Cloth Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: Can packaging tape be used for sealing packages with jewelry or valuables?

- Yes, packaging tape can be used for sealing packages with jewelry or valuables. Packaging tape is designed to provide a secure and durable seal, making it an excellent choice for ensuring the safety of your valuable items during shipping or transportation. It is strong and adhesive enough to securely close the package and protect the contents inside. However, it is always recommended to take additional precautions when shipping valuable items, such as using bubble wrap or cushioning material to provide extra protection.

- Q: Can packaging tape be used for sealing plastic garment bags?

- Indeed, plastic garment bags can be effectively sealed using packaging tape. The primary purpose of packaging tape is to create a reliable and long-lasting seal on diverse materials, such as plastic. By utilizing packaging tape, one can ensure that the plastic garment bag remains tightly sealed, thereby safeguarding the garments inside from dust, moisture, and other harmful substances. This, in turn, prevents any potential damage or dirtiness. Furthermore, packaging tape is typically user-friendly, as it can be effortlessly cut with a dispenser or a pair of scissors, which adds to its convenience when sealing plastic garment bags.

- Q: Does packaging tape have a specific adhesive strength?

- Packaging tape possesses a specific adhesive strength, indicating its ability to adhere to surfaces effectively. This strength is commonly quantified in ounces per inch (oz/in) or pounds per inch (lb/in). Several factors contribute to the adhesive strength of packaging tape, including the adhesive type, tape thickness, and backing material quality. To meet distinct requirements, various types of packaging tape offer different adhesive strengths, suitable for lightweight parcels or robust shipments. When selecting packaging tape, it is crucial to consider the intended application and package weight to ensure an appropriate adhesive strength match.

- Q: Can packaging tape be used for sealing chemical or hazardous material containers?

- Sealing chemical or hazardous material containers with packaging tape is not advised due to its lack of necessary properties for effective containment and prevention of leakage. These substances often necessitate specialized containers and sealing methods to ensure safety and compliance with regulations. These specialized containers are engineered to withstand the corrosive or reactive nature of the substances they hold, with seals designed to provide a secure and leak-proof closure. In contrast, using packaging tape can be risky as it may result in leakage, contamination, and exposure to harmful substances. It cannot reliably serve as a barrier against leaks or spills, potentially leading to accidents, injuries, or environmental harm. To properly seal chemical or hazardous material containers, it is recommended to use specific sealing materials that are specifically designed for this purpose. This may involve utilizing specialized caps, gaskets, or seals that are compatible with the specific substance being contained. Moreover, it is crucial to adhere to the guidelines and regulations provided by relevant authorities to ensure the safe handling, storage, and transportation of these materials.

- Q: Can packaging tape be used for sealing foam or bubble wrap?

- Yes, packaging tape can be used for sealing foam or bubble wrap. Packaging tape is designed to have a strong adhesive that adheres well to various surfaces, including foam and bubble wrap. By applying packaging tape to the edges or seams of foam or bubble wrap, you can securely seal and protect your items during shipping or storage. It is important to ensure that the tape is applied properly and firmly to provide a tight seal and prevent the foam or bubble wrap from coming loose.

- Q: When the box is sealed, the tape is very noisy and very harsh. What shall I do?

- General adhesive tape is a taste, the size of the taste depends on the formula of glue, low molecular weight content, taste will be larger, once adhesive tape, it has a very small taste tape, we have been using.

- Q: Can packaging tape be used for sealing glass jars?

- Yes, packaging tape can be used for sealing glass jars. It provides a strong and secure seal, ensuring the contents remain fresh and protected. However, it is important to note that specialized jar sealants or methods, such as canning lids or rubber seals, may be more suitable for long-term storage or preserving purposes.

- Q: How do I apply packaging tape evenly?

- To apply packaging tape evenly, start by ensuring that the surface is clean and dry. Hold the tape dispenser at a slight angle, allowing the tape to come out smoothly. Apply gentle pressure while moving the dispenser along the surface, keeping the tape taut and avoiding any wrinkles or folds. It's also helpful to run a finger or a flat object along the tape as you go to ensure it adheres evenly.

- Q: Can packaging tape be used for sealing plastic storage baskets?

- Yes, packaging tape can be used for sealing plastic storage baskets. Packaging tape is designed to be strong and adhesive, making it suitable for securing and sealing various types of materials, including plastic. By using packaging tape, you can effectively seal the openings or seams of plastic storage baskets, keeping the contents secure and protected. However, it is important to note that the longevity and effectiveness of the seal may depend on the quality and durability of the specific packaging tape used. Additionally, it is recommended to clean and dry the surface of the plastic storage baskets before applying the tape to ensure proper adhesion.

- Q: Can packaging tape be used for sealing packages with sharp edges or corners?

- Yes, packaging tape can be used for sealing packages with sharp edges or corners. Its strong adhesive properties and durability make it suitable for securing boxes and ensuring that the package remains intact, even when subjected to sharp edges or corners.

Send your message to us

Clear Packaging Tape MSDS - Cloth Tape Synthetic Rubber Adhesive 35micron Various Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords