Custom Packaging Tape South Africa - Clear BOPP Tape Colorful Adhesive Tape for Packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 5000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

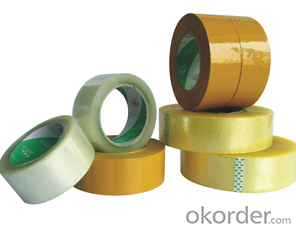

Clear BOPP Tape Colorful Adhesive Tape for Packing

1. Description of Clear BOPP Tape:

1.Carrier: BOPP film

2.Adhesive: Water based acrylic

3.Standard Size: 48mm*66m,50mm*50m,1.28*4000m etc.

4.Color: According to your request

5.Application: Widely sed for etc.

carton sealing and packing,light duty packing,bounding,holding and other office and household use.

2. Advantages of Clear BOPP Tape:

1 ) Different temperature resistance with good adhesion.

2 ) High tensile strength, good resistance of damage,no residue, eco-friendly.

3 ) Printing logo on paper core and carton mark as customers' need

4 ) SGS, ISO,BV, CTI certificates approved

5)Professional teamwork for orders

6)No.365 on the 2012 Fortune Global 500

7) Professional manufacturer with 31 years experiences of adhesive tapes

Special size,color can be made according to customer's requirement

3. Application of Clear BOPP Tape:

1) Used for normal masking, such as indoor painting, car painting, car decoration painting.

2) Used in electronic industry and electric appliances for fixing and protection purposes.

3) Mainly designed for ordinary wrapping ,craftwork, lightduty masking.

4) Furniture, appliance automobile /shoes spray painting, color making, decoration and labels.

4. Details of Clear BOPP Tape:

Material | BOPP film |

Used | Widely sed for etc. carton sealing and packing,light duty packing,bounding,holding and other office and household use. |

Printing | Offer printing |

Color | Red, milky, green, white , yellowish, blue, black, or at will. |

Packaging | 6rolls/shrink,12rolls/shrink,72rolls/ctn,144rolls/ctn. |

MOQ | 20ft container or as you need. |

Payment terms | 30% in advance,70% balance the copy of B/L. |

Delivery time | 15workdays except the affirming date of logo on paper core and carton after receiving the deposit. |

Jumbo rolls size

| 1260mm*1800m, 1260mm*1000m |

Width | 3mm~1260mm normal width:12mm,18mm,24mm,36mm

|

Length | 10m~1800m normal length: 20m,33m,50m,100m |

Port | Shenzhen |

Certifications | ISO.9001.2008. and SGS. |

Certification:

- Q: Can packaging tape be used for sealing protective packaging materials like bubble wrap?

- Yes, packaging tape can be used for sealing protective packaging materials like bubble wrap. It provides a secure and effective way to seal the packaging, ensuring that the contents remain protected during transportation or storage.

- Q: Does packaging tape come in different thicknesses?

- Yes, packaging tape does come in different thicknesses. Packaging tape is available in a variety of thicknesses to accommodate different needs and requirements. Thicker tapes are typically more durable and are suitable for heavy-duty applications where extra strength and resistance are necessary. On the other hand, thinner tapes are often used for lighter packages or general everyday use. The choice of thickness depends on the weight and size of the package being secured, as well as the level of reinforcement desired.

- Q: Does packaging tape come in different lengths for convenience?

- Packaging tape indeed comes in various lengths for ease of use. Different packaging tasks can be accommodated with packaging tape of different lengths. The commonly found lengths for packaging tape are 55 yards (50 meters) and 110 yards (100 meters). These lengths are specifically chosen to address diverse packaging needs and to ensure that there is an ample amount of tape to securely seal multiple packages without any shortage. Furthermore, the availability of different lengths provides the flexibility of selecting the most appropriate quantity of tape for individual packaging requirements, ensuring both convenience and cost-effectiveness.

- Q: Can packaging tape be used for sealing glass containers?

- Indeed, glass containers can be sealed using packaging tape. Packaging tapes are specifically engineered to offer a robust and reliable seal on diverse surfaces, glass included. When applied correctly, the tape adheres firmly to the glass, forming a secure seal that safeguards the container's contents. Nonetheless, it is crucial to acknowledge that not all packaging tapes are suitable for glass containers. It is advisable to utilize a tape explicitly designed for glass or a heavy-duty packaging tape with exceptional adhesive properties to guarantee an effective seal.

- Q: How does packaging tape perform in high-temperature conditions?

- Packaging tape generally performs well in high-temperature conditions, but its effectiveness may vary depending on the specific type and quality of the tape. Most packaging tapes are designed to withstand a range of temperatures and are typically heat-resistant up to a certain degree. However, it is important to note that extreme temperatures, particularly those exceeding the tape's specified heat resistance limit, can affect its adhesive properties and overall performance. In high-temperature conditions, the adhesive on packaging tape may soften or weaken, leading to reduced bonding strength and potential tape failure. This can result in packages opening or becoming less secure during transit or storage. Furthermore, heat can cause the tape to become less flexible, making it more prone to cracking or breaking. Hence, it is crucial to select packaging tape that is specifically designed for high-temperature environments if you anticipate exposure to extreme heat. Certain types of packaging tape, such as fiberglass-reinforced or high-temperature resistant tapes, are better suited for withstanding high temperatures. These tapes are often made with special adhesives and materials that offer enhanced heat resistance and improved performance in extreme conditions. They are designed to maintain their adhesive strength, bonding capability, and structural integrity even when exposed to elevated temperatures. In summary, while packaging tape can generally withstand high-temperature conditions, its performance may be compromised if subjected to extreme heat. Using tapes specifically designed for high-temperature environments can help ensure optimal performance and securely seal packages even in challenging conditions.

- Q: Can packaging tape be used for securing pallet loads?

- Yes, packaging tape can be used for securing pallet loads. It is commonly used to reinforce and stabilize palletized goods by securing them together, preventing shifting or toppling during transportation or storage.

- Q: How does packaging tape perform when exposed to chemicals or solvents?

- Packaging tape generally performs well when exposed to chemicals or solvents, but the specific performance may vary depending on the type of tape and the nature of the chemicals or solvents involved. Most packaging tapes are designed to have good resistance to common household chemicals such as cleaning agents, oils, and water-based solvents. They are typically made from materials like polypropylene or PVC, which have excellent chemical resistance properties. This allows the tape to maintain its adhesion and integrity even when exposed to moderate amounts of chemicals or solvents. However, it is important to note that some aggressive chemicals or solvents, such as strong acids or organic solvents, may have a detrimental effect on the performance of packaging tape. These highly corrosive substances can cause the tape to degrade, lose its adhesive properties, or even dissolve completely. To ensure optimal performance, it is recommended to check the specific chemical resistance properties provided by the manufacturer of the packaging tape. They may offer guidance on the suitability of the tape for different types of chemicals or solvents. Additionally, it is advisable to conduct small-scale tests or trials to assess the tape's performance when exposed to specific chemicals or solvents before using it for critical packaging applications. In summary, packaging tape generally performs well when exposed to common household chemicals or solvents. However, its performance may be compromised when exposed to aggressive or corrosive substances. It is important to consult the manufacturer's guidelines and conduct tests, if necessary, to ensure that the tape is suitable for the specific chemical or solvent it will be exposed to.

- Q: Can packaging tape be used for sealing construction or building materials?

- Yes, packaging tape can be used for sealing construction or building materials, but it may not provide the same level of durability and longevity as specialized tapes designed for such purposes.

- Q: Can packaging tape be used for sealing cardboard boxes?

- Yes, packaging tape is commonly used for sealing cardboard boxes as it provides a strong and secure bond.

- Q: Can packaging tape be used for sealing packages with irregular or uneven surfaces?

- Indeed, when it comes to sealing packages with uneven or irregular surfaces, packaging tape comes in handy. Its design is specifically tailored to stick to diverse surfaces, encompassing those that may lack smoothness or flatness. Thanks to its robust adhesive properties, packaging tape guarantees a secure seal, even on surfaces that may not be entirely even or smooth. Furthermore, the flexibility of packaging tape enables it to mold to the shape of the package, facilitating effective sealing on irregular surfaces. Nonetheless, it is crucial to apply the tape evenly and press it firmly onto the surface to fully exploit its sealing potential.

Send your message to us

Custom Packaging Tape South Africa - Clear BOPP Tape Colorful Adhesive Tape for Packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 5000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords