Clean Room Cotton Swabs SF-005 BB-003

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

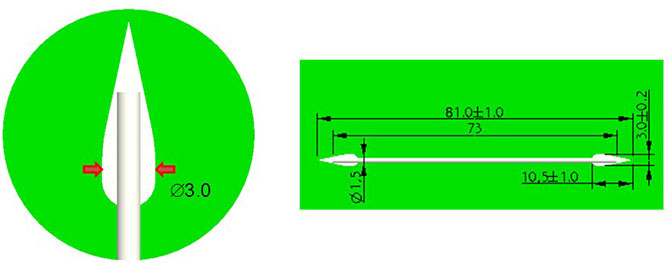

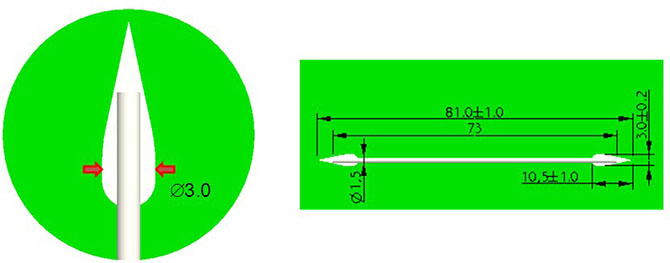

Product No.:SF-005 (BB-003)

Stick:3” Paper

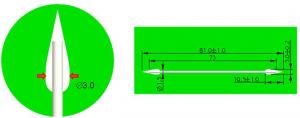

Stick Diameter:1.5mmØ

Tip Diameter:3.0+/-0.2mm

Tip Length:10.5+/-1.0mm

Total Length:81.0+/-1.0mm

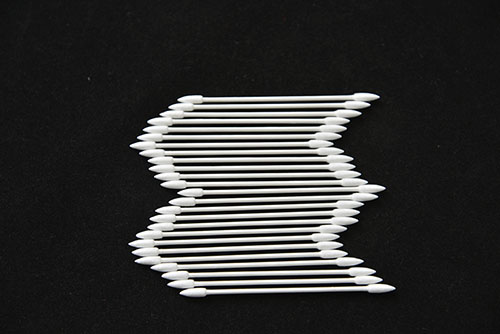

Packing Way:25pcs*100packs*10boxes

Carton Size:52*43*17cm

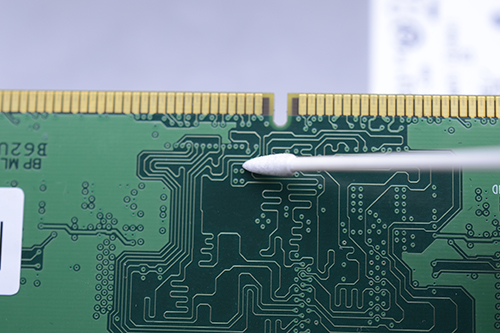

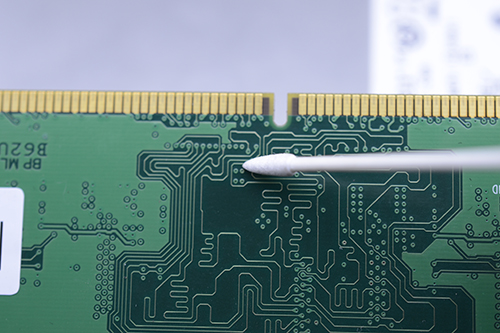

The clean room cotton buds are widely used in cleaning precise electronic components, laser, semi-conductor, optics lens, and magnetic read head etc. Our clean room cotton swabs can dip with DI Water, alcohol, IPA, and acetone solution. SF-005 is the perfect replacement of BB-003 in HUBY340 series.

- Q: What are the types of cleaning equipment

- That is too much There are all kinds of homes, there are all kinds of business, and there are all kinds of special things

- Q: What is the cleaning equipment?

- Cleaning equipment as the name suggests is designed for cleaning machinery and equipment, cleaning equipment play an effective cleaning effect, it reduces the labor cost of cleaning, and also improves the work efficiency and cleanness is indispensable to modern society.

- Q: What is the issue of cleaning equipment? Is there a difference between industrial cleaning equipment and common equipment?

- The highest rated working pressure of the industrial high pressure cleaning machine is much higher than the highest rated working pressure of the commercial high pressure cleaning machine. 2: under the same technical parameters (pressure flow), industrial high pressure cleaner can effectively continuously working time is more than commercial grade high pressure cleaner can effective working hours continuously. 3: under the same technical parameters (pressure flow), industrial high pressure cleaner of the pump head and the whole machine volume is greater than that of commercial grade high pressure cleaner pump head and engine volume. 4: under the same technical parameters (pressure flow), the value of industrial high pressure cleaner and service life is far greater than the value of commercial grade high pressure cleaner and service life. The pump head material of the industrial high pressure cleaning machine must be made of alloy steel, and the pump head of the commercial class high pressure cleaning machine usually USES copper or aluminum. Generally, the price is determined by several parameters. After all, it is more complicated, considering your needs and consulting the manufacturers. The company used in the previous company is the washing equipment made by chengdu power feng, the pre-sale and after-sale service is very good, you can also consult.

- Q: Introduction of geothermal cleaning equipment

- With the rapid development of geothermal energy market, people for the use of geothermal heating is also more and more widely, according to the statistics, pipeline scaling 1 mm, can to lower the water temperature is 6 ℃, therefore to geothermal users inconvenience caused damage to property and life. While geothermal heating and heating are common, the cleaning and maintenance of geothermal energy has become a big problem for us.

- Q: The main parameters of ultrasonic cleaning equipment

- Frequency: greater than 20KHz, which can be divided into low frequency, medium frequency, high frequency 3 segments. 2. The power density, power density = transmission power (W)/launch area (cm2) usually acuity 0.3 W/cm2, the higher the power density of the ultrasonic and cavitation effect is stronger, the faster, the better cleaning effect. But for delicate, surface finish, the high power density of long time can be used to "cavorate" the surface of the object. 3. The ultrasonic frequency, ultrasonic frequency is lower, the easier the cavitation in the liquid, the strength is big, has the stronger, is suitable for the workpiece (coarse, dirty) at the beginning of washing. High frequency of ultrasonic direction, suitable for fine cleaning. 4. Clean temperature: generally speaking, ultrasonic at 30 ℃ and 40 ℃ when cavitation effect is best. The higher the temperature, the greater the effect. Normally when actual application of ultrasonic wave, using the working temperature of 50 ℃ to 70 ℃.

- Q: Is it ok to clean the car with a dry ice cleaner?

- It's the best way to clean it up, it's just expensive. Because of the plane, numerical control machine, precise instrument is cleaned more frequently. There is also a lot of cleaning for cars, mainly for luxury cars.

- Q: Article 84 in GMP, the production equipment shall be cleaned according to the operating procedures specified in detail. Production equipment cleaning procedures shall stipulate detailed and complete cleaning methods, cleaning with the name of the equipment or tools, cleaning agents and preparation method, to remove the previous batch identification methods, protect already clean equipment before use from pollution methods, already clean equipment for the longest time limit, preserved...

- Last year took part in the issue of dedicated to verify training on cleaning validation Wang Yanzhong teacher to explain this one is so blue font: if you don't clean immediately after the equipment use, such as when a couple of days to clean again, need to confirm according to have validated cleaning method can clean the equipment when cleaning equipment, there may be some material put a few days after has been hard on the equipment surface, not as easy as immediately when cleaning clean. So the time that the device is used up to cleaning is going to be validated.

- Q: The oil can be cleaned by the tank cleaning and the cleaning of the tank is the cleaning of the machine

- The tank cleaning industry at present, the general take artificial cleaning, mechanical equipment cleaning tank is just rise recently, really can do mechanical cleaning also does not have a few, and some manufacturers are generally abroad, prices more expensive each device also need to around 10 million, as currently on the market what the robot cleaning tank while the price is cheaper, but the technology is relatively insecure, we cleaning company is this year just at the beginning of the year on a mechanical cleaning equipment, the effect is good, the key is cheap compact result, oil recovery rate can reach 90%, in the process of cleaning is content value.

- Q: Clean the cleaning parameters of the equipment

- Judge a ultrasonic cleaning machine general technical indicators as to stay ageing degree and resonant, impedance and impedance matching are already debugged before they go out, the key lies in you to do. Of course, the sound of ultrasonic cleaning machine and generator is now being silenced. The bonding mode of the oscillator is usually made of special cement, and the bolt fastening effect is good, but it is not suitable for maintenance. Frequency selection is cleaned according to the workpiece to decide, general material or on the surface is not very high, with 28 KHZ, more strict for cleaning, or had better choose high precision parts. This is because, the lower the frequency of the bubbles, the greater the when ultrasonic frequency is greater than 800 KHZ, there is no cavitation bubbles, this to be the effect of cleaning the surface of the cavitation corrosion is the lowest. In addition, the ultrasonic cleaning is the effect of the high pressure produced by an empty bubble in the instantaneous blast.

- Q: It is best to wash mechanical equipment using that cleaner

- It is recommended that the blue flying machine will be used for cleaning the surface of the equipment, cleaning the surface of the equipment and not damaging the paint on the surface of the equipment.

Send your message to us

Clean Room Cotton Swabs SF-005 BB-003

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords