Stainless Steel Wire Drawing Machine manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

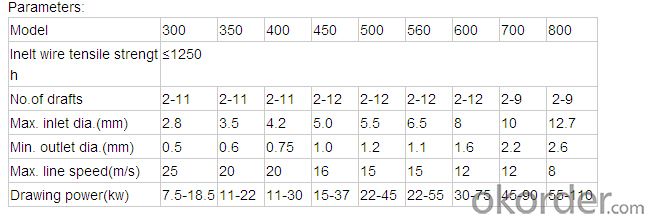

Specifications for Wire Drawing Machine

Straight Line Stainless Steel Wire Drawing Machine

1.electric parts adopt first-class brand at home and abroad.

2.PLC control.

Straight Line Stainless Steel Wire Drawing Machine

Description:

Straight Line stainless steel Wire Drawing Machine is mainly used for drawing various of metal wire from 6mm to 0.5mm , particularly suitable for drawing steel wire(high,medim,low carbon steel,stainless steel wire,prestressed wire,bead wire, rubber tube wire,spring steel wire,),welding wire(gas protection welding wire, submerged arc welding wire, flux-cored wire),alloy wire etc.

Technological process:

Pay-off---- Shell cleaning(pre-processing) ---- Wire rod pointing----(Buttering)----Drawing wire ---- Annealing ---- Take-up(spool or trunk take-up).

|

Main characteristics:

Reliability:Field bus technology was adopted to electrical control system,all digital control, electrical components are all international famous brand.Electrical control system is stable and reliable operation.

Energy saving: It adopts AC frequency regulator dragging which can reduce the impact of machine commission caused by motor start.

Security:It has multiple protection function, shield will open when the equipment high speed commission,or slow down to stop when meet other trouble.

High efficiency:It reduces the failure rate,average high working speed,greatly improve production efficiency.

Image for Wire Drawing Machine

|

| | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

.

- Q: What are the types of cleaning equipment

- The question you ask is unscientific, and there is no way to answer it at all At least a small class

- Q: What are the benefits of sanitation

- Love, what do you say is the advantage of washing your car every day

- Q: What are the cleaning facilities for the hotel?

- Hotel cleaning tools mainly dry off dust, mop/broom, trash, shovel, cleaning brush, pushing water scraping, telescopic rod, clean glass suits, spray bottle, safety rope, dust bag and so on. Again, we need to know some of the right ways to make a hotel clean. First, the items of different materials should take the corresponding hotel cleaning products for cleaning and maintenance. For example, if be glass ornament, should choose glass cleaner and glass cleanness tool; Stainless steel accessories, stainless steel maintenance agent; Wooden furniture, adorn article should choose the cleanness such as the household candle and so on. Moreover, the inside of the room health including bath crock, toilet, wash basin, cup, bed top grade, and so on, these equipment and facilities come into direct contact with the guest, must insist on a day after the guest use, cleaning, disinfection, replacement and maintenance, this will make the guest used more and more feel at ease.

- Q: What are the sanitation facilities?

- Hello: Solid waste collection and processing, sewage treatment, waste gas treatment, roller, mower, water jet many. Hope to adopt

- Q: What is the pool cleaning equipment

- Disinfection system (water treatment of swimming pool is very important, the water quality is not up to the standard to affect the opening) : Metering pump Drug delivery; Ozone generator. Lighting system (underwater lamp beautification swimming pool) : Pool wall lamp; Waterproof cable. Fully automatic thermostat (the temperature of the water in the swimming pool) : Fully automatic heating furnace; Water and water heat exchanger (commonly known as plate change); Temperature controller; Electric valve. Cleaning equipment (pool brush, leaf net, telescopic rod, suction head, wire brush). 5, the pool bank facility (escalator, departure stage). Water quality monitoring equipment (water quality monitor, test water box, water temperature meter). Water treatment pipe fittings.

- Q: How often do the reverse osmosis of pure water equipment wash the search?

- Generally 3 ~ 12 months clean, if every month had to be cleaned once, this explanation should improve the pretreatment system, adjust the running parameter. If you need to clean it once or three months, you will need to improve the operating level of the equipment, and it is difficult to determine if you need to improve the pretreatment system.

- Q: What cleaning equipment does the factory clean equipment need?

- A, plant, Workshop area mainly include workshop and warehouse, the characteristics of the environment is that difficult to clean and dirty, the area is large, the environment need to be efficient driving type washing machine, charge can clean the tens of thousands of square meters area, effectively improve the level of clean. Second, office space The office area usually is laid carpet according to need, so general can not use the ground machine. We need to use a vacuum cleaner for the daily cleaning of the carpet, and if we are not careful with the carpet, we need to use the suction machine. Carpet in the middle of care we need to use dry foam carpet cleaning machine, foam carpet cleaning machines and carpet washing machine and spray carpet smoking machine equipment, such as carpet of general and one month to do a thoroughly clean, can effectively remove dirt. When the carpet is cleaned in the long run, it is difficult to clean thoroughly in the middle and late stage, and then you need to use a carpet washing machine. The carpet washing machine can be used in the middle and later of the carpet to clean the carpet effectively, can make carpet the refurbishment work, the surprise that can surprise unexpectedly! Outdoor squares and open Spaces These places usually area is large, open, open, although it is difficult to clean, but not general cleaning requirements is very high, you just need to keep the floor clean. We recommend sweeping machines to remove dirt and dirt from the ground and keep it clean.

- Q: Article 84 in GMP, the production equipment shall be cleaned according to the operating procedures specified in detail. Production equipment cleaning procedures shall stipulate detailed and complete cleaning methods, cleaning with the name of the equipment or tools, cleaning agents and preparation method, to remove the previous batch identification methods, protect already clean equipment before use from pollution methods, already clean equipment for the longest time limit, preserved...

- This time is dirty time, oneself according to the production requirements for 3 days, 3 days after completing equipment use clean, if qualified, cleaning validation then SOP can regulation equipment should be used in within 3 days from the end of the cleaning.

- Q: What are the appliances cleaning equipment

- A steam engine, a steam engine Air conditioning cleaning machine Water heater cleaning machine Water cooler Multi-function sterilizer Geothermal cleaning machine Also not commonly used: suction blower, the hotel oil and smoke machine washing machine, washing machine ultrasonic cleaning machine, keyboard washing machine and so on

- Q: How do you clean the inside of the electric oven? Can you use a wire ball or a detergent?

- First wear latex gloves, detachable parts are removed inside the oven, such as baking, chassis, and then with a neutral detergent washing, paying special attention to oil dirties is very heavy, can use special cleaning fluid, such as the kitchen cleaner to do the key parts of decontamination. Then put an old newspaper in the door of an embedded oven and brush the broken pieces of the oven out of the oven with a small brush. Outside of the inside of the oven to heat pipe and heat pipe shield must use dry cloth to wipe gently, can't use a wet cloth, so as not to affect the heating pipe insulation, leakage phenomenon of short circuit. Except for the removable part of the oven, it is not possible to scrub clean and water with water or a wet cloth. If found the heating tube and fence are dirty, with dry cloth to wipe clean, also can not change with the rough surface such as steel wire ball, clean ball cleaning tools to wipe. If you have wire or hard particles falling into the heating tube, light barbecue an unpleasant feeling of anxious burnt flavour, or cause the entire circuit short circuit, can try to use clean force strong nylon cloth is wiped a few times more. After cleaning the heating tube, you can begin to clean the outer shell of the oven and the inside bladder. The cloth in the diluent of neutral detergent slightly wet, wipe with wet wipe the body shell, dip again after cleaning, diluent, and wring dry, into the oven inside pumice, final reoccupy clear water rinse wipe dry after dry, wipe it twice.

Send your message to us

Stainless Steel Wire Drawing Machine manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords