China Diamond Embossed Aluminum Coil - Best Quality Prepainted Aluminum Coil Hot Demanded

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Aluminium Prepainted Coil Best Quality and Hot Demanded Description:

Aluminium Prepainted Coil Best Quality and Hot Demanded are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Prepainted Coil Best Quality and Hot Demanded:

1)High flexibility.

2)Impact resistance.

3)Excellent weather-proof durablity.

4)Anti-ultraviolet.

5)Hight erosion resist.

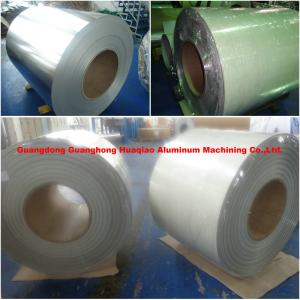

Images of Aluminium Prepainted Coil Best Quality and Hot Demanded:

Aluminium Prepainted Coil Best Quality and Hot Demanded Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Are aluminum coils suitable for architectural cladding?

- Architectural cladding can indeed utilize aluminum coils. Aluminum, a versatile and aesthetically pleasing material, is widely used in the construction industry due to its lightweight nature and durability. Aluminum coils can be easily shaped into various forms and sizes, making them perfect for architectural cladding applications. One of the notable advantages of using aluminum coils for cladding is their resistance to corrosion. Aluminum naturally develops a protective oxide layer, preventing rusting and deterioration over time. Consequently, aluminum proves to be a durable and low-maintenance option for architectural cladding. Moreover, aluminum coils offer a wide array of finishes and colors, providing greater design flexibility. Architects and designers can paint or coat them to match any architectural style or design concept, making aluminum coils a favored choice. Furthermore, aluminum is an environmentally friendly material. It is fully recyclable and has a significantly lower carbon footprint compared to cladding materials like steel or concrete. This makes aluminum coils a sustainable option for architectural projects. To sum up, aluminum coils are indeed suitable for architectural cladding due to their durability, corrosion resistance, design flexibility, and environmental benefits.

- Q: Is it possible to recycle old aluminum coils as scrap metal?

- <p>Yes, old aluminum coils can be used as a source of scrap metal for recycling. Aluminum is a highly recyclable material, and recycling it helps conserve resources and energy. Old aluminum coils can be melted down and repurposed into new aluminum products. It's important to ensure that the coils are clean and free of contaminants before recycling to maintain the quality of the recycled aluminum. Always check with local recycling centers or scrapyards for specific guidelines on recycling aluminum coils.</p>

- Q: A magnet will not attract a aluminum bar, but if you have an electromagnetic field made by an transformer it will interact.Why is that?Why iron is attracted and wood is not?

- Aluminum is not a magnetic material and will not be affected by stationary magnets. However, if a changing magnetic field is present, an electrical voltage will be induced in the aluminum ring and an electric current will flow as a result. This current will produce a magnetic field which will interact with the externally produced magnetic field. The key here is a changing magnetic field - because the voltage induced in the aluminum ring will be proportional to the rate of change of the field. If an aluminum disk is passed between the poles of a powerful magnet, eddy currents will be induced in the aluminum producing a magnetic field that will tend to retard the motion of the aluminum relative to the magnet. The changing field in this case is due to the motion of the aluminum. Iron is attracted to a magnetic field because it is a ferro-magnetic material. Wood is not a magnetic material, and it is not an electrical conductor, so it will not behave as aluminum does in a magnetic field.

- Q: We had a BBQ a few days ago and left our pack of aluminum foil on the table out side. It rained that night and the following night. I went out to take the trash out and heard a odd noise. It was the pack of foil boiling hot. The water from the rain was steaming out of it. When I picked it up you could feel the warmth coming from the center of it.It was 2 days after the BBQ, was never near the heat of that. It was on a separate table.The table is shaded all day, so it didn't heat from the sun. Plus aluminum does not transfer heat.It just don't make since to me. I unrolled some of it and it is dark grey from being heated so hot. I never heard of it and tried to find info, but to no avail. So out of curiosity I am asking.

- Aluminium is one of the best conductors of heat so the effect may have been a rare entropic incident where the water rapidly evaporated due to the warmth of the air. What's more likely is that the aluminium was exposed to the water and the rain was slightly penetrative. Aluminium usually has aluminium oxide protection to protect against corrosion and reaction but something may have depleted that layer causing a reaction and the gas you saw steaming wasn't water but hydrogen gas.

- Q: What are the disadvantages of using aluminum coils?

- One of the disadvantages of using aluminum coils is their susceptibility to corrosion. Aluminum is a reactive metal and can easily oxidize when exposed to moisture and certain chemicals, leading to corrosion and degradation of the coils over time. Additionally, aluminum coils may be more expensive compared to other coil materials such as copper, which can impact the overall cost of HVAC systems or other applications that utilize coils.

- Q: Can aluminum coils be used in transformer windings?

- Yes, aluminum coils can be used in transformer windings. Aluminum is a commonly used material for transformer windings due to its low resistivity, high conductivity, and cost-effectiveness compared to copper. It offers several advantages such as lighter weight, better thermal conductivity, and lower manufacturing cost. However, there are some considerations when using aluminum coils in transformer windings, such as the need for larger cross-sectional area to compensate for its lower conductivity compared to copper. Additionally, special techniques may be required to prevent galvanic corrosion when aluminum is in contact with other metals in the transformer. Overall, aluminum coils can be a suitable alternative to copper coils in transformer windings, offering benefits in terms of efficiency and cost.

- Q: Are aluminum coils suitable for air conditioning systems?

- Yes, aluminum coils are suitable for air conditioning systems. Aluminum coils offer excellent heat transfer properties, durability, and resistance to corrosion, making them a popular choice in air conditioning systems. They are lightweight, efficient, and can withstand high-pressure applications, making them a reliable option for cooling and refrigeration purposes.

- Q: This question asks about the impact of aluminum coils on the quality of welding. It seeks to understand the relationship between the material properties of aluminum coils and the outcomes of the welding process.

- <p>Aluminum coils can significantly affect welding quality due to their unique properties. Aluminum has a high thermal conductivity, which requires more energy to weld, and can lead to rapid heat dissipation, affecting the weld's uniformity. Oxides on the aluminum surface can also interfere with the welding process, causing porosity and poor joint strength if not properly cleaned. Additionally, aluminum's low melting point can lead to distortion and warping if not managed correctly. The use of appropriate filler materials, proper cleaning, and precise control of welding parameters are crucial to achieve high-quality welds with aluminum coils.</p>

- Q: Can aluminum coils be used for nameplates and labels?

- Yes, aluminum coils can be used for nameplates and labels. Aluminum is a versatile and durable material that can be easily shaped, engraved, or printed on. It is commonly used for manufacturing nameplates and labels due to its resistance to corrosion, lightweight nature, and ability to withstand harsh environments.

- Q: How do aluminum coils contribute to thermal management?

- The exceptional heat transfer capabilities of aluminum coils are crucial in thermal management. Aluminum possesses a high thermal conductivity, allowing it to efficiently transfer heat from one area to another. This quality plays a vital role in applications that require effective thermal management, including air conditioning systems, refrigeration units, and heat exchangers. In air conditioning systems, aluminum coils are commonly employed in the condenser and evaporator coils. The condenser coil releases heat from the refrigerant to the surrounding air, while the evaporator coil absorbs heat from the indoor air to cool it down. The high thermal conductivity of aluminum ensures efficient heat transfer between the refrigerant and the surrounding air, resulting in faster and more effective cooling. Similarly, refrigeration units utilize aluminum coils in the evaporator coils to extract heat from the interior space. The aluminum coils assist in removing heat from the refrigerated area and transferring it to the outside environment, maintaining a lower temperature inside the unit. Heat exchangers, which are utilized in various industries like automotive, power generation, and HVAC, also benefit from aluminum coils. Heat exchangers are devices that transfer heat between multiple fluids with different temperatures. Aluminum's high thermal conductivity enables efficient heat exchange between the fluids, enhancing overall system performance and energy efficiency. Furthermore, aluminum coils possess lightweight properties and are resistant to corrosion, making them durable and suitable for long-term use in harsh environments. These characteristics further contribute to effective thermal management by ensuring reliable heat transfer and reducing the risk of system failure or decreased efficiency. In conclusion, aluminum coils play a crucial role in thermal management systems by facilitating efficient heat transfer, expediting cooling or heating processes, and improving overall system performance. Their high thermal conductivity, lightweight nature, and corrosion resistance make them the preferred choice in various applications requiring effective thermal management.

Send your message to us

China Diamond Embossed Aluminum Coil - Best Quality Prepainted Aluminum Coil Hot Demanded

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords