Cheapest Decent General Purpose Crepe Paper Masking Tape

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 880 roll

- Supply Capability:

- 90000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General purpose of General Purpose Crepe Paper Masking Tape

1) good adhesive

2) good flexibility

3) No residual left

4) Different sizes are available

Feature of General Purpose Crepe Paper Masking Tape

general purpose masking tape, adhesive tape, paper tape.

1) good adhesion. 2) good flexibility.

-General purpose masking tape is made of crepe paper coated with natural rubber adhesives.

-It is designed for interior paint masking, light-duty packaging, holding, bundling, splicing and packaging.

-Practical for construction, building, home, office or industrial applications.

-Jumbo roll, log roll and cut roll are available.

-The width of jumbo roll is from 980mm - 1250mm

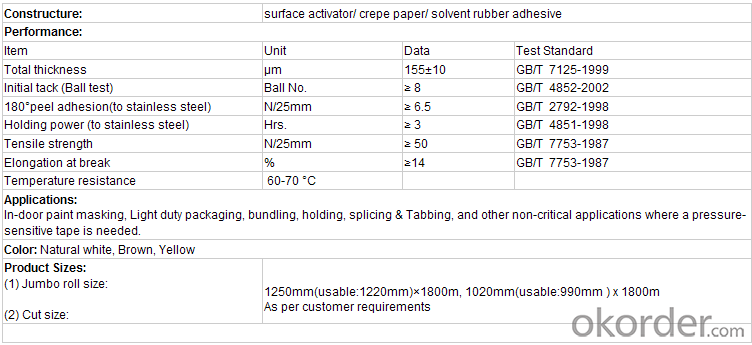

Specifications of General Purpose Crepe Paper Masking Tape

Advantages of General Purpose Crepe Paper Masking Tape :

Different temperature resistance with good adhesion

High tensile strength, good resistance of damage, no residue, eco-friendly

Accept custom design

SGS, ISO, BV, CTI certificates approved

Professional teamwork for orders

No.267 on the 2014 Fortune Global 500

Professional manufacturer with 31 years experiences of adhesive tapes

Special size, color can be made according to customer's requirement.

Our Services

Your inquiry related to our product & price will be replied within 24 hours.

Well-trained & experienced staff can answer all your inquiries in English or other language

Your business relationship wit us will be confidential to any third party

Good after-sale service offered please free feel to contact us for more information

FAQ

Q 1: Do you have any MOQ of Wonder Masking Tape?

A: Yes, according to the size you need.

Q 2: What is the delivery time?

A: Sample time 7 days, 30 days for the mass production.

Q 3: Can we put our logo on the products?

A: Yes, welcome.

Q 4: How should I pay for you if I place order to you?

A: Usually, 30% T/T deposit in advance, 70% balance against the copy of B/L.

- Q: Can packaging tape be used for outdoor applications?

- Outdoor applications can indeed make use of packaging tape. However, it is vital to recognize that not all packaging tapes are designed for outdoor use. Regular packaging tapes may not endure extreme weather conditions or UV ray exposure, leading to deterioration or loss of adhesive properties. To guarantee the durability and efficiency of packaging tape for outdoor applications, it is advisable to opt for specialized outdoor or weather-resistant packaging tapes. These tapes are engineered with stronger adhesives and materials that can withstand outdoor elements like rain, heat, cold, and sunlight. They are often composed of materials such as acrylic or rubber, which offer superior resistance to moisture, temperature changes, and UV rays. When selecting packaging tape for outdoor applications, it is crucial to take into account the specific requirements of the intended use. This may involve factors like the duration of exposure to outdoor conditions, the weight and size of the package, and the surface to which the tape will be applied. By choosing the appropriate outdoor packaging tape, you can ensure that your packages remain securely sealed and protected, even when subjected to outdoor environments.

- Q: Can packaging tape be used for sealing protective packaging materials like bubble wrap?

- Yes, packaging tape can be used for sealing protective packaging materials like bubble wrap. Packaging tape is designed to provide a strong and secure seal on various types of materials, including bubble wrap. It is commonly used in packaging and shipping industries to ensure that the contents of a package are well-protected and secure during transit. When using packaging tape to seal bubble wrap, it is important to apply the tape along the edges of the bubble wrap to create a tight seal and prevent any potential damage or exposure.

- Q: Is packaging tape resistant to chemicals?

- Packaging tape typically exhibits resistance against a broad array of chemicals. Commonly, packaging tapes are crafted from materials like polypropylene or polyvinyl chloride (PVC), renowned for their chemical-resistant properties. These materials possess the capacity to endure exposure to different chemicals, including solvents, acids, and bases. Nevertheless, it is crucial to acknowledge that the degree of chemical resistance can vary depending on the specific type and quality of the packaging tape utilized. Certain tapes may display higher chemical resistance compared to others. Furthermore, the tape's resistance can be influenced by the duration and intensity of chemical exposure. To guarantee the tape's chemical resistance, it is advisable to review the manufacturer's specifications and guidelines concerning chemical compatibility. If you are handling exceedingly harsh chemicals or engaging in specialized applications, it may be necessary to seek out packaging tapes explicitly designed for those specific conditions.

- Q: What are the considerations for using packaging tape on painted surfaces?

- When considering using packaging tape on painted surfaces, there are several important considerations to keep in mind. Firstly, it is crucial to assess the type and condition of the paint on the surface. If the paint is old, flaking, or in poor condition, using packaging tape may cause further damage such as peeling or chipping off the paint. In such cases, it is advisable to avoid using tape directly on the painted surface. Another important consideration is the adhesive strength of the packaging tape. Some tapes have strong adhesives that may stick firmly to the painted surface, making it difficult to remove without damaging the paint. It is recommended to test a small, inconspicuous area with the tape to ensure it can be safely removed without leaving residue or causing any harm. Furthermore, it is crucial to consider the duration for which the tape will be applied. If the tape is intended to be left on the painted surface for an extended period, there is a higher risk of it causing damage. Over time, the adhesive may bond more strongly with the paint, making it harder to remove without causing any harm. Additionally, the surface texture plays a role in determining the suitability of using packaging tape. Rough or uneven surfaces may not allow the tape to adhere properly, leading to lifting or peeling, which can damage the paint. Lastly, it is essential to consider the purpose of using packaging tape on the painted surface. If the objective is to protect the paint from scratches or damage during transportation or storage, alternative methods such as using protective sheets or bubble wrap may be more suitable and less likely to harm the paint. In conclusion, when considering using packaging tape on painted surfaces, one must assess the type and condition of the paint, adhesive strength, duration of application, surface texture, and the purpose of using the tape. By taking these considerations into account, one can ensure that the tape is used safely without causing any damage to the painted surface.

- Q: What are the benefits of using double-sided packaging tape?

- There are several benefits of using double-sided packaging tape. Firstly, it provides a strong and secure bond between two surfaces. This makes it ideal for packaging applications where you need to ensure that the contents stay in place during transit or storage. The double-sided tape creates a strong adhesive bond that holds the packaging materials together, minimizing the risk of items shifting or becoming damaged. Secondly, double-sided packaging tape is versatile and can be used for various purposes. It can be used to seal boxes, attach labels or documents, or even mount lightweight objects. This versatility makes it a valuable tool for both personal and professional packaging needs. Another benefit is that double-sided packaging tape is easy to use. Unlike traditional packaging tapes that require you to apply adhesive on both surfaces, double-sided tape already has adhesive on both sides, making it a convenient option. It saves time and effort as you simply need to peel off the backing and apply the tape to the desired surface. Furthermore, double-sided packaging tape offers a neat and clean appearance. Since the tape is hidden between the surfaces it is bonding, it creates a seamless look without any visible tape lines. This can be particularly useful when packaging gifts or products that need to maintain a professional and presentable appearance. Lastly, double-sided packaging tape is often designed to be durable and long-lasting. It can withstand various environmental conditions, such as temperature changes, humidity, or exposure to moisture, without losing its adhesive properties. This ensures that your packaging remains intact and secure for an extended period. In summary, the benefits of using double-sided packaging tape include strong adhesion, versatility, ease of use, a clean appearance, and durability. Whether you are packaging items for personal or professional purposes, double-sided packaging tape can provide a reliable and efficient solution.

- Q: Does packaging tape have any specific certifications or standards?

- Yes, packaging tape can have specific certifications or standards. There are various organizations and standards that set guidelines for packaging materials, including packaging tape. One of the most common certifications for packaging tape is the International Organization for Standardization (ISO) certification. ISO sets standards for quality management systems, and packaging tape can be certified under ISO 9001:2015, which ensures that the product meets certain quality criteria. In addition to ISO certification, packaging tape can also adhere to specific industry standards such as ASTM International standards or European Union directives. ASTM International develops and publishes technical standards for a wide range of materials, including packaging tape. These standards ensure that the tape meets specific requirements related to strength, adhesion, and durability. Furthermore, some packaging tapes may have certifications related to their environmental impact. For example, certain tapes may be certified as recyclable, biodegradable, or made from sustainable materials. These certifications can be obtained from organizations like the Forest Stewardship Council (FSC) or the Sustainable Forestry Initiative (SFI), which promote responsible forestry practices. It is important to note that not all packaging tapes will have certifications or adhere to specific standards. However, if a packaging tape does have certifications or complies with certain standards, it signifies that the product meets certain quality, performance, or environmental criteria.

- Q: Can packaging tape be used for sealing plastic clamshell packaging?

- Indeed, plastic clamshell packaging can be effectively sealed using packaging tape. Tailored to securely seal a wide range of packaging materials, packaging tape boasts a robust adhesive bond that effectively binds the clamshell packaging, thereby preventing any unwanted opening during the transportation or handling stages. Moreover, the durability and tear resistance of packaging tape guarantee the continuous protection and sealing of the clamshell packaging throughout the entirety of its distribution journey.

- Q: Does packaging tape come in different widths for different applications?

- Yes, packaging tape does come in different widths to cater to various applications.

- Q: The tape is left on the door. The glue has dried for a long time. What chemicals can be used to remove it without damaging the paint?

- 3, buy a bottle of glue only 20 yuan, a lot of places can use. Also can use for a long time4, use strong adhesive tape to put some decorations on the door, and then remove, visible, the door left a piece of glue mark. Use gasoline or kerosene can erase the tape, buy 1200 water sandpaper to wipe water speckle trace, buy a pot of transparent varnish, banana oil to dilute, brush brush once a response to light. Do not use nail polish brush to wipe, can go to the gum stains, but the door will become a misty white spot.5. First scrape the sticky tape with a knife, then wipe it with petroleum essence. Then the frosted glass will be wiped off with the turpentine and then wipe with turpentine.

- Q: How do I prevent packaging tape from becoming too loose?

- To prevent packaging tape from becoming too loose, it is important to ensure that the surface being taped is clean and free from any dirt or debris. Additionally, applying firm and consistent pressure while securing the tape can help create a stronger bond. If the tape still becomes loose, using a wider tape or applying multiple layers can provide better adhesion and prevent it from coming undone.

Send your message to us

Cheapest Decent General Purpose Crepe Paper Masking Tape

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 880 roll

- Supply Capability:

- 90000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords