Ceramic Fiber Textiles Cloth 1240 Grade for Hot Blast Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

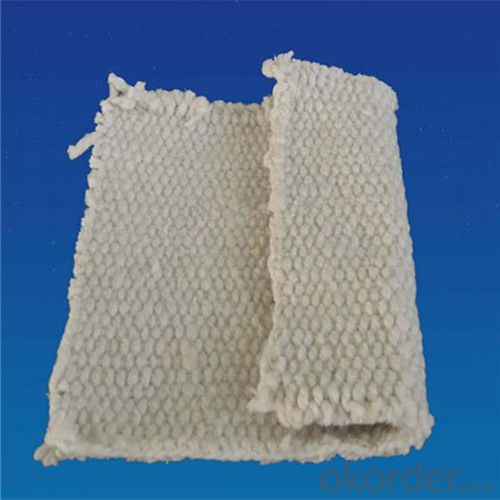

General Information of Ceramic Fiber Cloth

l Ceramic fiber cloth is a high performance industrial cloth manufactured from ceramic fiber yarn.

l Ceramic fiber cloth is reinforced by a core of glass filament or chrome-nickel wire for high strength retention at elevated temperature.

l Ceramic fiber cloth can be used as protection against high temperature, barrier to prevent fire spreading, welding curtains and blankets, furnace curtains, high temperature electricity insulation, cable and fuel line protection, fireproof wrap, etc

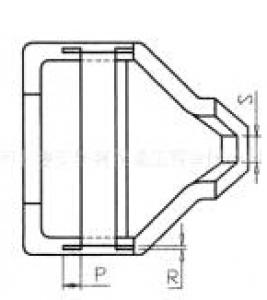

Size of Ceramic Fiber Cloth

Thickness: 2mm-10mm (2/25”-3/8”)

Characteristics of Ceramic Fiber Cloth

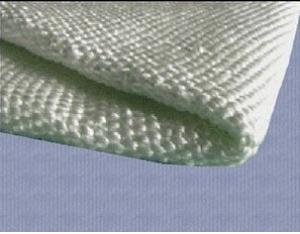

Low thermal conductivity, low heat storage, high temperature stable, thermal shock resistant

Fire and flame proof

Chemical resistant, compatible with most corrosive chemicals, commonly used acid and alkali (exceptions are hydrofluoric, phosphoric acids and concentrated alkalis)

Lightweight, woven texture with excellent handling strength,

Size of Ceramic Fiber Cloth

Thickness: 2mm-10mm (2/25”-3/8”)

Application of Ceramic Fiber Cloth

Safety and protective insulation cover, curtains, blanket, welding blanket

Expansion joint fabric

Insulation wrapping material for cable, wire, pipe, exhaust, etc

Gaskets, tadpole gasket and other high temperature insulation seal

Image of Ceramic Fiber Cloth

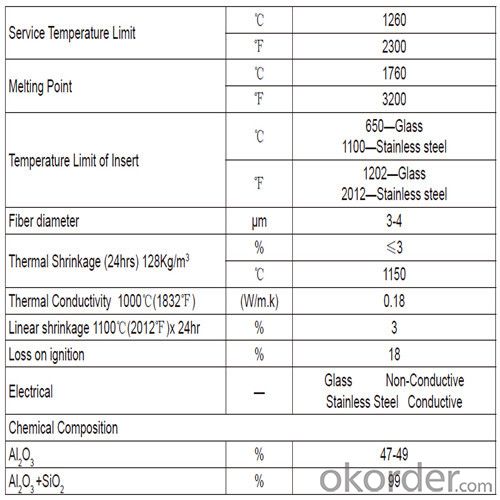

Technical Data of Ceramic Fiber Cloth

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisors.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

- Q: What is the function of (ceramic) ceramic powder?

- According to different porcelain stent materials are divided into: metal porcelain powder, pure titanium porcelain powder, casting porcelain powder, two alumina porcelain powder, zirconia porcelain powder, etc.. According to the temperature is divided into: high temperature porcelain powder, medium temperature porcelain powder, low temperature porcelain powder.

- Q: Is everybody's ceramic fiber cloth poisonous?

- With aluminum, zinc and other non-ferrous molten metal erosion capacity. Excellent high temperature strength. The bottom heat conductivity makes the product have good heat insulation performance. Excellent electrical insulation performance. Non-toxic, harmless, no adverse effects on the environment, excellent tensile properties.

- Q: Can ceramic fibers be spun?

- Ceramic fiber itself is relatively brittle, silk is relatively short, spinnability, but after adding viscose (differential polyester glass fiber, even pulp) as the heart can be spun,

- Q: What are the uses of ceramic fiber blankets?

- The ceramic fiber blanket has a strong resistance to wind erosion, and can be directly contacted with flame and high-speed airflow. Because of its excellent fire resistance, high temperature stability, high thermal shock resistance, low heat capacity and high temperature conditions, high compressive strength.

- Q: What's the temperature of the high temperature ceramic fiber cloth and ceramic drill cloth?

- The ceramic fiber cloth is only one kind of one thousand degree temperature resistance. It is reinforced cloth for steel wire.

- Q: What are the differences between digital textile printing ink and printing ink?

- 1. heat transfer ink:Transfer printing for polyester, nylon and spandex fabrics;2. active ink:Suitable for direct spray onto pure cotton, silk, nylon and other fabrics;

- Q: What are the man-made fibers polluting the environment?

- [] is a man-made fiber synthetic fiber as raw materials by using natural polymer cellulose or protein compounds in nature (such as wood, cotton, rice straw, bagasse fiber or milk, soybean, peanut protein, etc.) through a series of chemical and mechanical processing and made of cotton, wool and silk as similar to the textile fiber. Such as artificial cotton, rayon and so on.

- Q: The difference between ceramic fiber cloth and ceramic fiber paper

- Ceramic fiber paper and ceramic fiber cloth are refractory insulation materials, which can be used for insulation and heat preservation

- Q: Which is better, ceramic fiber or spray velvet?

- Ji'nan Huolong thermal ceramics limited liability company to help you analyze: thrown silk and spray cotton, which is better? Which process is more suitable for producing carpets? Fire dragon energy saving from the technical point of view is as follows:1, fiber diameter: rejection fiber more coarse, rejection filament fiber is generally 3.0-5.0 mu m, spinneret fiber is generally 2.0-3.0 mu m;2, the length of fiber yarn: rejection fiber longer, the rejection of silk fiber is generally 150-250mm, spinneret fiber is generally 100-200mm;3, the coefficient of thermal conductivity: spray cotton fiber is lower than that of the thrown silk;4, the tensile and flexural strength: thrown silk because fiber thicker than that of spraying cotton;

- Q: Does the component of textiles contain 70% acrylic? Does it hurt the body?

- Acrylic has high transparency, light transmittance of 92%, a "plastic crystal" reputation. And excellent weather resistance, especially for outdoor, in other plastic crown, and has a good surface hardness and gloss, processing plasticity, can be made into a variety of shapes and products needed. There are a wide variety of boards, rich in color (including translucent swatches), and another feature is that the plate is still able to maintain high transparency.

Send your message to us

Ceramic Fiber Textiles Cloth 1240 Grade for Hot Blast Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords