Ceramic Fiber Textiles - High Quality Standard Small Zirconia Ceramic Tube for Optical Fiber Wire with Manufactured

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Type: | Ceramic Parts | Application: | Structure Ceramic | |

| Material: | Zirconia Ceramic, zirconia ceramic | Model Number: | AV-zirconia ceramic structure | Brand Name: | AV |

| delivery time: | 30-45working days | characteristic: | high hardness/Anticorrosion/high temperature resistance | Surface: | Good Polished |

| Used in: | Textile industrial | life time: | Long service life | MOQ:: | 1Pcs |

| Payment terms: | 100%TT in advance |

Packaging & Delivery

| Packaging Detail: | Standard export packing |

| Delivery Detail: | 30-45days after receiving your payment |

Specifications

Manufacture of zirconia ceramic structure

Anticorrosion and eco-friendly

temperature resistance

Best price with good quality

Zirconia ceramic struction/Zirconia ceramic rod/aluminium ceramic struction

Zirconia grinding media is the most durable and efficient media for ball milling and attrition milling of ceramic material

Zirconia grinding media provides a virtually contamination-free ball milling solution for a variety of industries.

Advantages of Zirconia Grinding Media:

1)Ultra low wear loss as a result of the transformation-toughening mechanism unique to the yttrium stabilited zirconia(YST) material system

2)Higher grinding efficiency and reduced grinding time due to the higher density of zirconia (compared with alumina and glass)

3)Most durable grinding material, reducing operational cost in the long run. Wear rate substantially lower than Al2O3, CeO2-ZrO2, and MgO-ZrO2 grinding media.

4)Suitable for high velocity operations and wet grinding operations.

Technical Specifications:

Property | Unit | Parameter |

Content | wt% | 94.6% ZrO2 5.2%Y2O3 |

Packing density | kg/L | 3.5 (Dia5mm) |

Density | g/cm3 | 6.00 |

Hardness(HV) | GPa | >12 |

Elastic modulis | GPa | 200 |

Thermal conductivity | W/m.K | 3 |

thermal Expansion coefficient | 10×10-6/°C (20 to 400) | 9.6 |

Pressing intensity | KN | ≥25(Dia5mm) |

Fracture tenacity | MPam½ | 8 |

Grain size | µm | ≤0.5 |

Specification Available:

Ball:Dia0.8,Dia1.0,Dia1.2,Dia1.4,Dia1.6,Dia1.8,Dia2,Dia3,Dia5,Dia6.5,Dia7,Dia8.5,Dia10,Dia12,Dia15,Dia20,Dia25,Dia30,Dia35mm ect;

Cylinder:Dia5×5,Dia7×7,Dia10×10,Dia12.7×12.7,Dia15×15,Dia20×20mm, ect.

Applications:

1, For grinding wear-resistant, corrosion-resistant products: paints, textiles, paints, printing and dyeing

2, For grinding high strength, high toughness products: magnetic materials, piezoelectric ceramics, dielectric ceramics

3,To prevent pollution: medicine, food, cosmetics

4, Ceramics: Electronic ceramics, refractory ceramics, structural ceramics

- Q: Is aluminum silicate fiber completely insulated from heat transfer?

- Aluminum silicate fiber module in the well sealed at the same time, the thickness of heat insulation protection cases, can be isolated from the transfer of hot air to the maximum, complete isolation is not possible, the total fiber trolley furnace as an example, long-term use temperature of one thousand degrees, in addition to the door is sealed by the ceramic fiber packing do seal

- Q: What is the function of (ceramic) ceramic powder?

- According to different porcelain stent materials are divided into: metal porcelain powder, pure titanium porcelain powder, casting porcelain powder, two alumina porcelain powder, zirconia porcelain powder, etc.. According to the temperature is divided into: high temperature porcelain powder, medium temperature porcelain powder, low temperature porcelain powder.

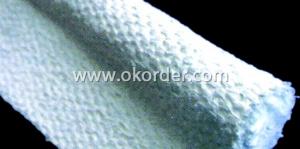

- Q: Is everybody's ceramic fiber cloth poisonous?

- Aluminum silicate fiber textiles can replace asbestos textiles, widely used in metallurgy, chemical industry, ceramics. Glass, refractories, shipbuilding, aerospace, automotive, machinery, electronics, building materials, light industry and other industrial sectors of the fire-resistant, heat insulation, fire prevention, friction, sealing, silencing, labor protection, high temperature filtering etc..

- Q: Can ceramic fibers be spun?

- The utility model can also achieve higher strength by increasing metal wire reinforcement, and finally can be made into products such as yarn, cloth, belt, rope, packing, etc., and the utility model has wide application.

- Q: What are the uses of ceramic fiber blankets?

- Ceramic fiber blanket is mainly used for high temperature, tough, self bearing high strength of the place, but also used for high airflow speed, mechanical destruction of large places. Ceramic fiber blanket can be used in these occasions.

- Q: What's the temperature of the high temperature ceramic fiber cloth and ceramic drill cloth?

- Ceramic fiber cloth, stainless steel wire, enhanced use temperature of 1050 degrees, glass fiber reinforced use temperature of 650 degrees.

- Q: What are the differences between digital textile printing ink and printing ink?

- Under the new economic environment, the textile industry will enter a short process, digital production mode. Nowadays, more and more printing and dyeing mills use wide format inkjet printing to produce.

- Q: The difference between ceramic fiber cloth and ceramic fiber paper

- 1. appearance. The ceramic fiber cloth has an obvious grid like appearance, and the ceramic fiber paper is very few or even mesh like.2. density. The density of ceramic fiber paper is greater than that of ceramic fiber cloth.3. thickness. Ceramic fiber paper, the thinnest can do 0.5mm, ceramic fiber paper can not do so thin, generally thin, there are also 2mm.4. stand erect. Ceramic fiber paper can be like in our life that can be placed on the A4 paper, mold, stand up. Ceramic fiber cloth is like the fabric used in our 5. lives. It's soft and doesn't stand upright.6. tear resistance. The toughness of the ceramic fiber paper is not as good as that of the ceramic fiber cloth.

- Q: Which is better, ceramic fiber or spray velvet?

- Different applications of two kinds of ceramic fiber cotton:In 1, production of HLGX ceramic fiber module: rejection due to thick and long silk fiber is better than spraying silk carpet, in the block made of the folding process, blowing fiber blankets easily broken and torn, and thrown silk fiber blanket can be folded very closely and not easy to damage, the quality will directly affect the block lining quality;The vertical layer 2, large boiler insulation blanket shop carpet fiber application: rejection due to long and thick, has better tensile resistance, more durable, so the rejection is better than spray carpet carpet;3, application of ceramic fiber textile, silk fiber thick and long and has good spinnability, the ceramic fiber thrown silk became the production of ceramic fiber textiles (cloth, tape, rope, pipe and other special materials);

- Q: Does the component of textiles contain 70% acrylic? Does it hurt the body?

- Acrylic may sound strange, because it is a new word that has appeared on the mainland in the last two years. It was not until 2002 that the advertising industry, furniture industry and handicraft industry were gradually understood by a few. "Acrylic" is a transliteration of foreign words, English is ACRYLIC, it is a chemical material. The chemical name is called "PMMA", which belongs to propylene alcohol, commonly known as "specially treated organic glass". In the application industry, its raw materials usually appear in the form of particles, plates, pipes and so on.

Send your message to us

Ceramic Fiber Textiles - High Quality Standard Small Zirconia Ceramic Tube for Optical Fiber Wire with Manufactured

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords