Ceramic Fiber Textiles Cloth with Fire and Flame Proof

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

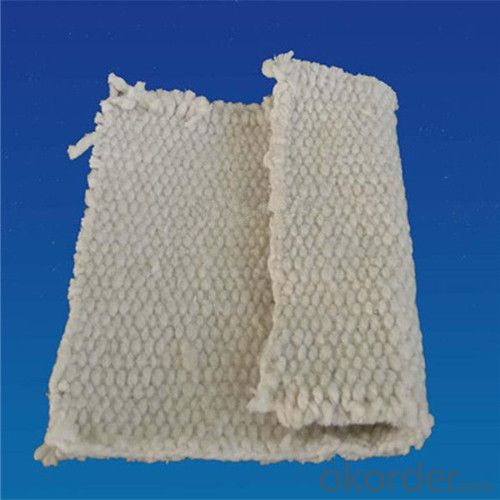

General Information of Ceramic Fiber Cloth

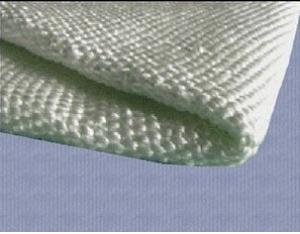

Ceramic fiber cloth is a woven fabric that is manufactured from high purity alumino-silicate based ceramic fiber, reinforced with fiberglass filament and optional alloy steel wire. The ceramic fiber cloth is white and odorless, suitable for high temperature applications up to 2300°F.

Characteristics of Ceramic Fiber Cloth

Low thermal conductivity, low heat storage, high temperature stable, thermal shock resistant

Fire and flame proof

Chemical resistant, compatible with most corrosive chemicals, commonly used acid and alkali (exceptions are hydrofluoric, phosphoric acids and concentrated alkalis)

Lightweight, woven texture with excellent handling strength,

Size of Ceramic Fiber Cloth

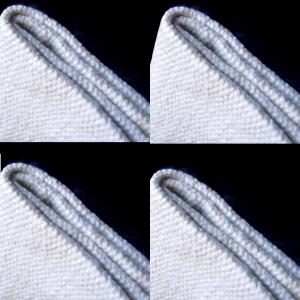

Thickness: 2mm-10mm (2/25”-3/8”)

Application of Ceramic Fiber Cloth

Safety and protective insulation cover, curtains, blanket, welding blanket

Expansion joint fabric

Insulation wrapping material for cable, wire, pipe, exhaust, etc

Gaskets, tadpole gasket and other high temperature insulation seal

Image of Ceramic Fiber Cloth

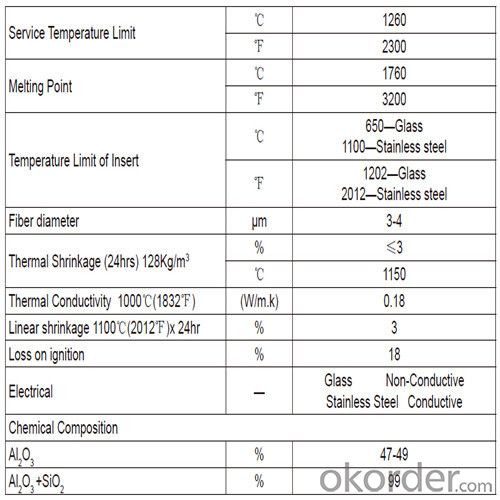

Technical Data of Ceramic Fiber Cloth

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

FAQ

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

- Q: Is aluminum silicate fiber completely insulated from heat transfer?

- Aluminum silicate fiber module in the well sealed at the same time, the thickness of heat insulation protection cases, can be isolated from the transfer of hot air to the maximum, complete isolation is not possible, the total fiber trolley furnace as an example, long-term use temperature of one thousand degrees, in addition to the door is sealed by the ceramic fiber packing do seal

- Q: What is the function of (ceramic) ceramic powder?

- According to different porcelain stent materials are divided into: metal porcelain powder, pure titanium porcelain powder, casting porcelain powder, two alumina porcelain powder, zirconia porcelain powder, etc.. According to the temperature is divided into: high temperature porcelain powder, medium temperature porcelain powder, low temperature porcelain powder.

- Q: Is everybody's ceramic fiber cloth poisonous?

- Aluminum silicate fiber textiles can replace asbestos textiles, widely used in metallurgy, chemical industry, ceramics. Glass, refractories, shipbuilding, aerospace, automotive, machinery, electronics, building materials, light industry and other industrial sectors of the fire-resistant, heat insulation, fire prevention, friction, sealing, silencing, labor protection, high temperature filtering etc..

- Q: Can ceramic fibers be spun?

- The utility model can also achieve higher strength by increasing metal wire reinforcement, and finally can be made into products such as yarn, cloth, belt, rope, packing, etc., and the utility model has wide application.

- Q: What are the uses of ceramic fiber blankets?

- Ceramic fiber blanket is mainly used for high temperature, tough, self bearing high strength of the place, but also used for high airflow speed, mechanical destruction of large places. Ceramic fiber blanket can be used in these occasions.

- Q: What are the differences between digital textile printing ink and printing ink?

- Under the new economic environment, the textile industry will enter a short process, digital production mode. Nowadays, more and more printing and dyeing mills use wide format inkjet printing to produce.

- Q: What are the man-made fibers polluting the environment?

- Fibers are roughly divided into natural fibers, man-made fibers, and synthetic fibers[natural fiber] refers to the natural growth or formation of fiber, including plant fiber (natural cellulose fiber), animal fibers (natural protein fiber) and mineral fiber. Plant fibers include: seed fiber, phloem fiber, leaf fiber, and fruit fiber. Seed fiber is the unicellular fiber that grows from the epidermal cells of some plant seeds. Such as cotton, kapok. Bast fiber is a single fiber or process fiber obtained from the phloem of some plants. Such as: linen, ramie, jute. Leaf fiber is the process fiber obtained from the leaves or sheaths of some plants. Such as: sisal, abaca. Fruit fiber is the fiber obtained from the fruit of some plants. Coconut fiber. An animal fiber (natural protein fiber) that includes hair, fiber, and gland fibers. Hair follicles: fibers of the hair follicles that have multicellular structures and are composed of keratin. Such as: wool, cashmere, camel hair, rabbit hair, Ma Haimao. Silk fibers: fibers formed from the glands of some insects, especially those produced by lepidopteran larvae, and fibers formed by secretions of some mollusks. Such as: silk.

- Q: The difference between ceramic fiber cloth and ceramic fiber paper

- 1. appearance. The ceramic fiber cloth has an obvious grid like appearance, and the ceramic fiber paper is very few or even mesh like.2. density. The density of ceramic fiber paper is greater than that of ceramic fiber cloth.3. thickness. Ceramic fiber paper, the thinnest can do 0.5mm, ceramic fiber paper can not do so thin, generally thin, there are also 2mm.4. stand erect. Ceramic fiber paper can be like in our life that can be placed on the A4 paper, mold, stand up. Ceramic fiber cloth is like the fabric used in our 5. lives. It's soft and doesn't stand upright.6. tear resistance. The toughness of the ceramic fiber paper is not as good as that of the ceramic fiber cloth.

- Q: Which is better, ceramic fiber or spray velvet?

- Different applications of two kinds of ceramic fiber cotton:In 1, production of HLGX ceramic fiber module: rejection due to thick and long silk fiber is better than spraying silk carpet, in the block made of the folding process, blowing fiber blankets easily broken and torn, and thrown silk fiber blanket can be folded very closely and not easy to damage, the quality will directly affect the block lining quality;The vertical layer 2, large boiler insulation blanket shop carpet fiber application: rejection due to long and thick, has better tensile resistance, more durable, so the rejection is better than spray carpet carpet;3, application of ceramic fiber textile, silk fiber thick and long and has good spinnability, the ceramic fiber thrown silk became the production of ceramic fiber textiles (cloth, tape, rope, pipe and other special materials);

- Q: Does the component of textiles contain 70% acrylic? Does it hurt the body?

- Acrylic may sound strange, because it is a new word that has appeared on the mainland in the last two years. It was not until 2002 that the advertising industry, furniture industry and handicraft industry were gradually understood by a few. "Acrylic" is a transliteration of foreign words, English is ACRYLIC, it is a chemical material. The chemical name is called "PMMA", which belongs to propylene alcohol, commonly known as "specially treated organic glass". In the application industry, its raw materials usually appear in the form of particles, plates, pipes and so on.

Send your message to us

Ceramic Fiber Textiles Cloth with Fire and Flame Proof

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords