Low Thermal Conductivity Ceramic Fiber Textiles

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m³

- Supply Capability:

- 68 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Low Thermal Conductivity Ceramic Fiber Yarn

Product Description:

Ceramic fiber yarn is made from high quality clay, high purity alumina and silica oxides by spun or blown process. Ceramic fiber yarn has a range of products: ordinary type, standard form, high-purity type, high-alumina type and containing zirconium type. Different types of products use different materials. The performance of ceramic fiber yarn is also different, and they are suitable for different working temperatures.

Ceramic fiber yarn can be used after optional cutting. When storing ceramic fiber yarn, pay attention to moisture. The high-alumina type and containing zirconium type products can be directly used as furnace linings.

Product Features:

• Low thermal conductivity

• High tensile strength

• Resilient to thermal shock

• Corrosion resistance

Product Specifications:

Al Content (%): 32-55

Type: 1260℃ STD/HP, 1350℃ HA, 1430℃ HZ

Density: 64-160kg/m³

Size: 12.5×610×14400mm, 25×610×7200mm, 50×610×3600mm

Product Packing:

Plastic bag in a carton box

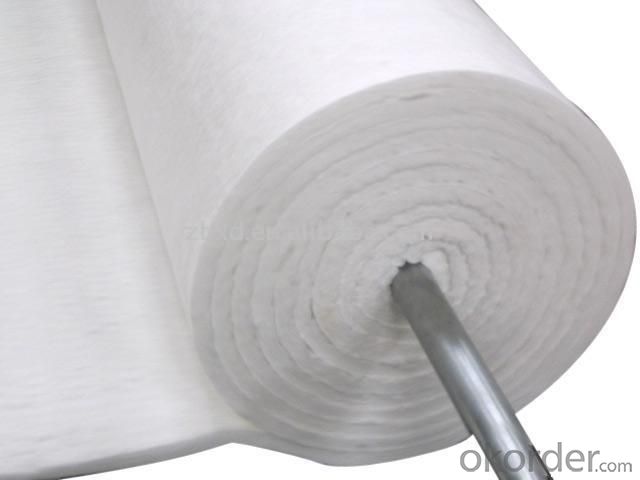

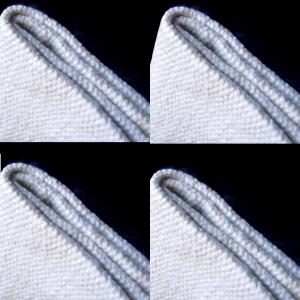

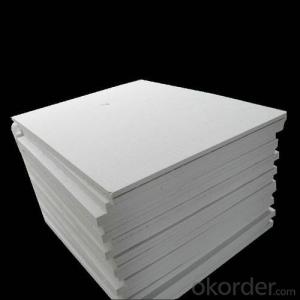

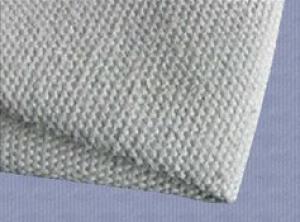

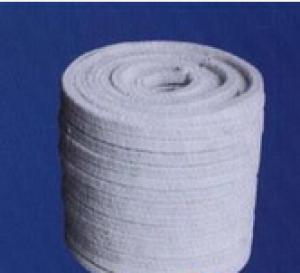

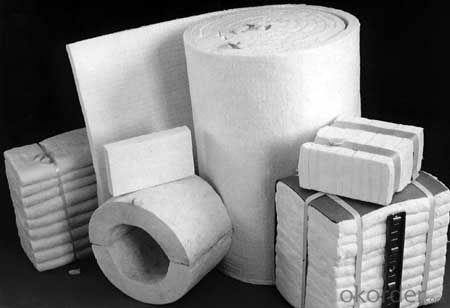

Product Images:

◆Product Process

◆Packaging

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What other products does OKorder offer?

A3: We offer a full range of refractory bricks, mortar, cement, ceramic fiber products, and more.

Q4: Where are Ceramic Fiber products used?

A4: Ceramic fiber products have many advantages, including: high temperature stability, lightweight, superior insulation, and ease of application. Fiber products are available in a variety of product forms to solve a range of thermal management application problems across various industries. The main industrial market segments that use ceramic fiber and soluble fiber products are the aluminum, iron, steel, heat treatment, power, incineration, boilers, and glass industries.

Q5: What kind of Ceramic Fiber should I use?

A5: When selecting the fiber type for a particular application, it is important to consider all factors. If the fiber/fabric will not have to support a load at temperature, the lower-cost industrial grade fibers may be appropriate. However, if the fiber will be load bearing at temperature as in ceramic matrix composites, then one of the composite grade fibers would be a better choice. Of course there may be other factors, such as corrosion, chemical resistance, or atmospheric conditions that may require trade-off in the selection process.

- Q: Is aluminum silicate fiber completely insulated from heat transfer?

- Fire-resistant insulation layer is used to make ceramic fiber module insulation, thermal insulation thickness of four hundred mm, the ceramic fiber blanket double extrusion, ceramic fiber module in parallel sorting, the trolley furnace wall temperature to plate temperature rise of forty-five degrees, which is almost a best isolation effect.

- Q: What is the function of (ceramic) ceramic powder?

- Opaque porcelain: cover the color of the base crown and increase the retentionNeck edge porcelain: also called neck porcelain, darker color, showing neck colorBody porcelain: also called dentin porcelain, the main porcelain powder, used to obtain the natural beauty of dentinEnamel porcelain: also called cut end porcelain, used for cutting ends, translucencyTransparent porcelain: reflects the natural and transparent shape of teethGlaze powder: colorless and transparent, simulating the luster of enamelThere are modified porcelain, dyed porcelain, gums, porcelain and so on, can show different colors and special restoration needs.

- Q: Is everybody's ceramic fiber cloth poisonous?

- Aluminum silicate fiber textiles can replace asbestos textiles, widely used in metallurgy, chemical industry, ceramics. Glass, refractories, shipbuilding, aerospace, automotive, machinery, electronics, building materials, light industry and other industrial sectors of the fire-resistant, heat insulation, fire prevention, friction, sealing, silencing, labor protection, high temperature filtering etc..

- Q: Can ceramic fibers be spun?

- Ceramic fiber itself is relatively brittle, silk is relatively short, spinnability, but after adding viscose (differential polyester glass fiber, even pulp) as the heart can be spun,

- Q: What are the uses of ceramic fiber blankets?

- The ceramic fiber blanket has a strong resistance to wind erosion, and can be directly contacted with flame and high-speed airflow. Because of its excellent fire resistance, high temperature stability, high thermal shock resistance, low heat capacity and high temperature conditions, high compressive strength.

- Q: What's the temperature of the high temperature ceramic fiber cloth and ceramic drill cloth?

- The ceramic fiber cloth is only one kind of one thousand degree temperature resistance. It is reinforced cloth for steel wire.

- Q: What are the differences between digital textile printing ink and printing ink?

- The advantages of ink-jet printing methods are: the traditional printing plate making process is omitted, shorten the process and reduce the cost; reduce the dye waste to obtain environmental friendly; digital image to facilitate the design and innovation of small batch flexible production and other traditional printing incomparable advantages.

- Q: What are the man-made fibers polluting the environment?

- Fibers are roughly divided into natural fibers, man-made fibers, and synthetic fibers[natural fiber] refers to the natural growth or formation of fiber, including plant fiber (natural cellulose fiber), animal fibers (natural protein fiber) and mineral fiber. Plant fibers include: seed fiber, phloem fiber, leaf fiber, and fruit fiber. Seed fiber is the unicellular fiber that grows from the epidermal cells of some plant seeds. Such as cotton, kapok. Bast fiber is a single fiber or process fiber obtained from the phloem of some plants. Such as: linen, ramie, jute. Leaf fiber is the process fiber obtained from the leaves or sheaths of some plants. Such as: sisal, abaca. Fruit fiber is the fiber obtained from the fruit of some plants. Coconut fiber. An animal fiber (natural protein fiber) that includes hair, fiber, and gland fibers. Hair follicles: fibers of the hair follicles that have multicellular structures and are composed of keratin. Such as: wool, cashmere, camel hair, rabbit hair, Ma Haimao. Silk fibers: fibers formed from the glands of some insects, especially those produced by lepidopteran larvae, and fibers formed by secretions of some mollusks. Such as: silk.

- Q: Which is better, ceramic fiber or spray velvet?

- Ji'nan Huolong thermal ceramics limited liability company to help you analyze: thrown silk and spray cotton, which is better? Which process is more suitable for producing carpets? Fire dragon energy saving from the technical point of view is as follows:1, fiber diameter: rejection fiber more coarse, rejection filament fiber is generally 3.0-5.0 mu m, spinneret fiber is generally 2.0-3.0 mu m;2, the length of fiber yarn: rejection fiber longer, the rejection of silk fiber is generally 150-250mm, spinneret fiber is generally 100-200mm;3, the coefficient of thermal conductivity: spray cotton fiber is lower than that of the thrown silk;4, the tensile and flexural strength: thrown silk because fiber thicker than that of spraying cotton;

- Q: Does the component of textiles contain 70% acrylic? Does it hurt the body?

- Acrylic has high transparency, light transmittance of 92%, a "plastic crystal" reputation. And excellent weather resistance, especially for outdoor, in other plastic crown, and has a good surface hardness and gloss, processing plasticity, can be made into a variety of shapes and products needed. There are a wide variety of boards, rich in color (including translucent swatches), and another feature is that the plate is still able to maintain high transparency.

Send your message to us

Low Thermal Conductivity Ceramic Fiber Textiles

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m³

- Supply Capability:

- 68 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords