Ceramic Fiber Paper - White Heat Resistant Paper for Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The ceramic fiber are manufactured from high purity raw material alumina powder ,silica sand for the high temperature grades and zircon sand is also used. The ceramic mixture is heated in an high temperature electric furnace and the stream of molten material is drawn into fibers by either spinning or blowing .It is produced by advanced “blown” and “spun” processes . It is featured with high temperature resistance and heat insulation and high anti-melt capability, very low thermal conductivity, chemical corrosion resistance and thermal shock stability.Product coverage areas including petrochemical industry, steel industry, aluminum industry, metallurgy industry.

Product Applications:

Ceramic Fiber Bulk are ideal for use in the below applications

Industial thermal insulation and sealing corrosion resistance material, such as industrial furnace and steel pipe or metal casting

Thermal and electiical insulation meterial

Instrument equipment inslution material

Kiln cr deck covering for insulaiton

Product Advantages:

CNBM has success in its ceramic fiber products due to their cost-effectiveness and excellent insulating properties. CNBM also has experience in ceramic fiber blankets application and would like to assist you in product selection, system design, and installation techniques.

Main Product Features:

Low thermal conductivity , low thermal capacity,and excellent thermal insulation property.

High chemical stability ,resistance to corrosion ,excellent eletric insulation property

Good flexibility and toughness,easy to cut or install quickly

Good thermal stability and resistance to thermal shock.

Good sound absorption and mechanism strength

Non-asbestos,low slag ball content

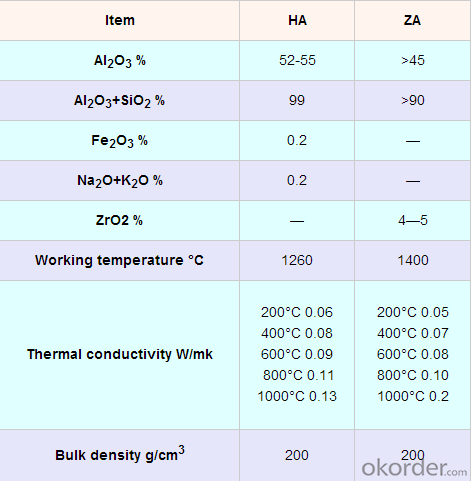

Product Specifications:

FAQ:

Q1.What is your MOQ?

A1 :MOQ may vary by customer's special requirement; we try our best to meet your business requirement.

Q2.Can you provide sample?

A2: Yes, we can offer sample , and some samples are free

Q3:Can you delivery by express?

A3: Yes, we can delivery by any express

Q4.Can you accept OEM ?

A4: YES! We can according your demand to produce.

Product Picture

- Q: Which insulation effect is better compared with ceramic fiber for STP insulation board?

- Solid energy saving STP insulation board, its insulation performance than traditional ceramic fiber insulation material is better than 3~4 times

- Q: Can ceramic fibers be spun into fibers, please?

- TolerableToday's ceramic fiber fabrics are rope, cloth, tape, yarn, clothing, etc.

- Q: How are ceramic fiber papers attached to the interior wall?

- There are two ways to apply ceramic fiber paper to the wall. The first is to buy ceramic fiber paper with single-sided adhesive tape, and the second is to paste it directly with double-sided adhesive tape. From Ji'nan dragon hot ceramics limited liability company, refractory materials chapter

- Q: Why is there no direct relationship between thermal conductivity and conductivity of ceramics?

- The concept of electrical conductivity in physics, in which the product of the quantity and the electric field intensity is equal to the conduction current density. For isotropic media, conductivity is scalar; for anisotropic media, conductivity is tensor. In ecology, conductivity is the ability to conduct current by means of a numerically expressed solution. The unit is expressed in SIEMENS per meter (S/m). The conductivity is simply the product of the measured conductivity (G) and the conductance cell constant (L/A). Here the L is the length of the liquid column between two plates and the A is the area of the plate. P l=l/ = sigma (1) definition or explanation for the reciprocal of resistivity conductivity. Sigma Rho =1/ (2): units in the international system of units, the conductivity of the unit is SIEMENS / m. (3) the physical meaning of conductivity is to indicate the conductivity of a substance.

- Q: What is ceramic fiber paper? What is ceramic fiber paper for?

- The manufacture of ceramic fiber paper was originally made of minerals! The production process is as follows: the ore is melted at high temperature, then the ceramic fiber is made by throwing the yarn, and finally, a lightweight insulating refractory material is made by wet forming process.

- Q: Do fiberglass or ceramic fiber paper have insulation effect?

- Second, in the case of temperature can be met, glass fiber cotton insulation better. The main advantage of ceramic fiber is to make gaskets and the like.

- Q: The difference between ceramic fiber cloth and ceramic fiber paper?

- 1. appearance. The ceramic fiber cloth has an obvious grid like appearance, and the ceramic fiber paper is very few or even mesh like.2. density. The density of ceramic fiber paper is greater than that of ceramic fiber cloth.3. thickness. Ceramic fiber paper, the thinnest can do 0.5mm, ceramic fiber paper can not do so thin, generally thin, there are also 2mm.4. stand erect. Ceramic fiber paper can be like in our life that can be placed on the A4 paper, mold, stand up. Ceramic fiber cloth is like the fabric used in our 5. lives. It's soft and doesn't stand upright.6. tear resistance. The toughness of the ceramic fiber paper is not as good as that of the ceramic fiber cloth.

- Q: Carbon fiber and aluminum alloy material in the end what is the difference?

- The advantages of carbon fiber are light, excellent corrosion resistance, good elasticity and outstanding vibration absorption effect. The disadvantage is that the shock resistance is poor and the high temperature resistance is poor. It is used in a lot of planes, boats, sporting goods, such as bicycles, tennis rackets and so on. But the price is much more expensive than aluminum alloy.

- Q: The difference between the ceramic fiber blanket and rock cotton blanket?

- Refractory ceramic fiber material is a lightweight and efficient thermal insulation material. It has the following advantages over traditional heat insulation materials:Ceramic fiber as lining, low volume density: ceramic fiber lining than light heat insulation brick lining light more than 75%, lighter than light castable lining light 90% to 95%. If using fiber lining, it can greatly reduce the steel structure load and prolong the service life of the furnace.

- Q: How high is the temperature resistance of the ceramic fiber gasket?

- Generally divided into standard type and high profile, the standard temperature of 1260 degrees to 1000 degrees of long-term use of high alumina long-term use of 1200 degrees.

Send your message to us

Ceramic Fiber Paper - White Heat Resistant Paper for Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords