High Temperature Furnace Ceramic Fiber Paper

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Fiber Paper for High Temperature furnace

The ceramic fiber are manufactured from high purity raw material alumina powder ,silica sand for the high temperature grades and zircon sand is also used. The ceramic mixture is heated in an high temperature electric furnace and the stream of molten material is drawn into fibers by either spinning or blowing .It is produced by advanced “blown” and “spun” processes .Ceramic fiber bulk shows a high temperature stability ,low weight and heat capacity and an outstanding sound absorption is complemented by their resistance to oxidation and reduction

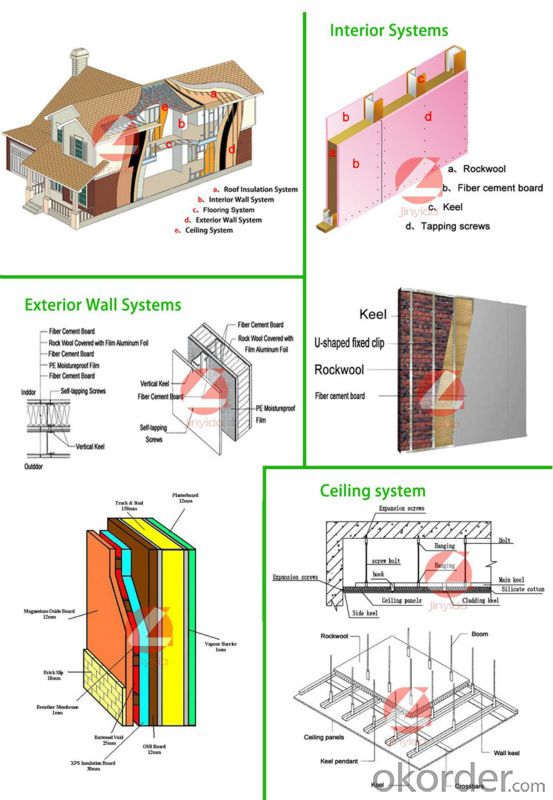

Product Applications:

Ceramic Fiber Bulk are ideal for use in the below applications

The industry kiln, heating device, high temperature pipe lining

Power boiler,gas turbine and heat and nuclear power insulation

Chemical industrial high temperature equipment and heating

equipment lining

Fireproof and heat insulation for high building

Heat insulation for Kiln door and roof.

High-grade household appliances thermal insulation device

High temperature filtration etc

Product Advantages:

CNBM has success in its ceramic fiber products due to their cost-effectiveness and excellent insulating properties. CNBM also has experience in ceramic fiber blankets application and would like to assist you in product selection, system design, and installation techniques.

Main Product Features:

•Easy twisting, shaping and cutting

•Excellent machining performance

•Excellent tensile strength

•Acoustic performance

•Good anti-spalling properties

•Low thermal conductivity, low thermal capacity

•Resistance to wind and erosion, long service life

•Excellent thermal insulation, fire protection,

•Thermal insulation and acoustic performance

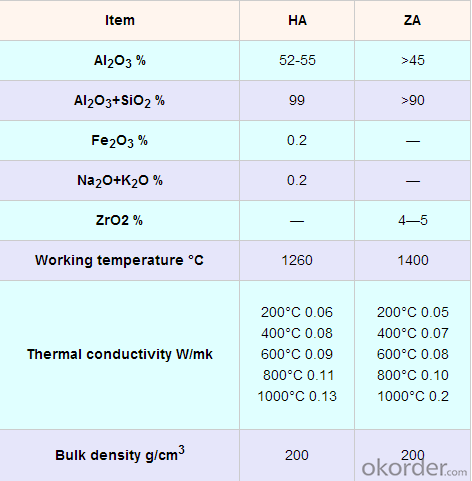

Product Specifications:

Product Picture

Produce Processing

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

- Q: Ceramic fiber insulation moisture-proof, but also play a cooling effect?

- Then use the compressed air jet or use the wire throwing machine to turn the yarn into a fiber. After the cotton collector sets the cotton, it forms the ceramic fiber cotton.Fiber cotton can be further processed into fiber blanket, board, paper, cloth, rope and other products.

- Q: Is the slag ball of the ceramic fiber useful?

- Slag balls are basically useless, just like raw ore.

- Q: The condition of ceramic glass fiber at high temperature

- Generally speaking, the glass fiber has low temperature resistance, and the biggest use is glass fiber reinforced plastic; the ceramic fiber has higher temperature resistance, and the biggest purpose is to be used as the structural material of refractory bricks, but generally it does not form fabric;

- Q: What's the fire resistance of the ceramic fiber?

- The most important index of porcelain refractory fiber is the diameter and thermal stability of the fiber. Al2O3SiO2 fiber is commonly used in ceramic industry. It is divided into different application range according to the content of Al2O3, and Cr2O3 material is introduced into it to improve its refractory and oxidation resistance. Generally high alumina content, iron oxide and other impurities of low fiber products are pure white, the introduction of chromium oxide fiber is sold with milk yellow tone color. The average diameter of the ceramic fiber is 24 microns. High fiber, small density, low thermal conductivity, high temperature. If the fiber is coarse and dense, the use is not satisfactory. The thermal stability index of fiber is more important. Al2O3-SiO2 fiber products range between 1260 and 3588% in line shrinkage. The amount of shrinkage is also directly related to thermal stability.

- Q: Do ceramic fiber paper smell at high temperature?

- Ceramic fiber paper is made from high purity ceramic fibers, with a small amount of scientifically selected and tightly controlled binders, and binders will evaporate during use. If the ceramic fiber paper in a high temperature environment, the bond will gradually volatile, volatile initial will have a certain odor, and so volatile, there will be no flavor. The binder is a series of organic rubber, and the smell remains as little as possible.

- Q: Aluminum silicate blanket is used for heat preservation tube or aluminium silicate ceramic fiber paper

- The heat preservation of the pipe is usually made of aluminium silicate fiber blanket. The heat preservation of the base is made of aluminium silicate ceramic fiber paper. The insulation of the pipe is very little.

- Q: What is the essential difference between the standard of ceramic fiber and ordinary aluminium silicate?

- High fiber, small density, low thermal conductivity, high temperature. If the fiber is coarse and dense, the use is not satisfactory. The thermal stability index of ceramic fiber products (aluminum silicate fiber products) is more important. The range of Al2O3SiO2 fiber contraction in various products of 1260 C line is 35 - 88%. The amount of shrinkage is also directly related to thermal stability. Ceramic fiber products (aluminum silicate fiber products) as ceramic fiber products (aluminum silicate fiber products) with low thermal conductivity, low density, light weight, light steel frame are used in the design and construction of kilns supporting structure, so that the development of ceramic kiln kiln into the "lightweight" era. The fiber has small heat storage and is suitable for quick heating and cooling firing. Flexible fibers can be processed into products with grooves or openings, and has good resistance to mechanical shock and impact ability, chemical stability is good, these advantages for the development of new kiln, and spread to the development of ceramic industry, have an important role in promoting. Ceramic fiber products (aluminum silicate fiber products) the ceramic fiber products (aluminum silicate fiber products) products: carpet, blanket, block, a variety of products like fiber, dispersion of fiber paper and vacuum forming, the work is generally in the range 871 to 1427 DEG C, under special circumstances can be short-term in the limit of high temperature above the use.

- Q: What are the features of ceramic fiber gaskets?

- 1) the continuous use temperature can reach 1000 DEG C, and the service temperature can reach 1260 DEG C for a short time.2) has good acid and alkali corrosion resistance and aluminum, zinc and other molten metal melting ability.3) good high temperature strength and heat insulation performance (refer to physical and chemical indexes).4) having a higher level of electrical insulation and high temperature electrical insulation than glass fibers.5) non-toxic, harmless and odorless.

- Q: How to paste the ceramic fiber paper on the iron plate?

- Not used in high temperature industry, then with double-sided adhesive can be.

- Q: The difference between the ceramic fiber blanket and rock cotton blanket?

- The heat capacity (heat storage capacity) of ceramic fiber lining is low: the heat capacity of ceramic fiber is only about l/10 of light heat resistant lining and light castable lining, and the heat capacity of lining material is proportional to the weight of lining. Low heat capacity means the furnace in the reciprocating operation absorb less heat and heating speed, greatly reducing the operational control of the temperature in energy consumption, especially for heating furnace and furnace, furnace shutdown has obvious energy saving effect.

Send your message to us

High Temperature Furnace Ceramic Fiber Paper

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords