Ceramic Fiber Paper 1260C (2300F) - 1430C (2600F) Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Fiber Paper 1260c (2300F) -1430c (2600F) Refractory

The ceramic fiber are manufactured from high purity raw material alumina powder ,silica sand for the high temperature grades and zircon sand is also used. The ceramic mixture is heated in an high temperature electric furnace and the stream of molten material is drawn into fibers by either spinning or blowing .It is produced by advanced “blown” and “spun” processes .Ceramic fiber bulk shows a high temperature stability ,low weight and heat capacity and an outstanding sound absorption is complemented by their resistance to oxidation and reduction

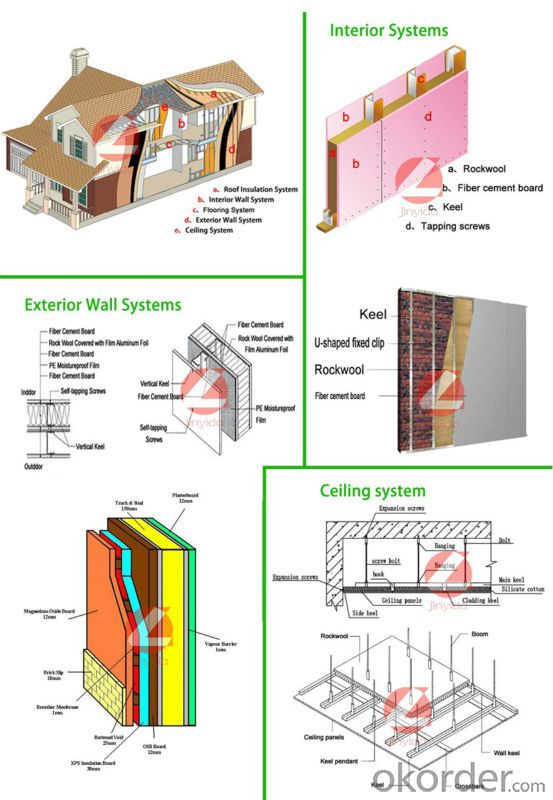

Product Applications:

Ceramic Fiber Bulk are ideal for use in the below applications

The industry kiln, heating device, high temperature pipe lining

Power boiler,gas turbine and heat and nuclear power insulation

Chemical industrial high temperature equipment and heating

equipment lining

Fireproof and heat insulation for high building

Heat insulation for Kiln door and roof.

High-grade household appliances thermal insulation device

High temperature filtration etc

Product Advantages:

CNBM has success in its ceramic fiber products due to their cost-effectiveness and excellent insulating properties. CNBM also has experience in ceramic fiber blankets application and would like to assist you in product selection, system design, and installation techniques.

Main Product Features:

•Easy twisting, shaping and cutting

•Excellent machining performance

•Excellent tensile strength

•Acoustic performance

•Good anti-spalling properties

•Low thermal conductivity, low thermal capacity

•Resistance to wind and erosion, long service life

•Excellent thermal insulation, fire protection,

•Thermal insulation and acoustic performance

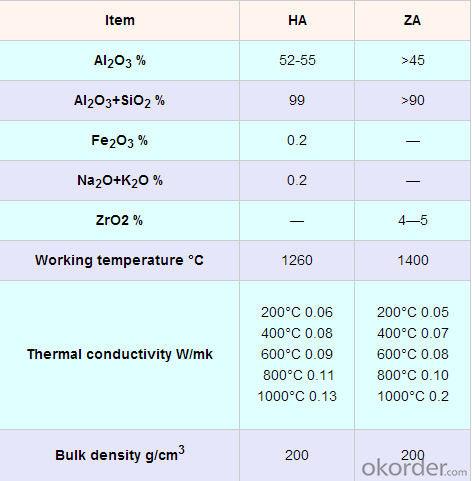

Product Specifications:

FAQ:

Q1.What is your MOQ?

A1 :MOQ may vary by customer's special requirement; we try our best to meet your business requirement.

Q2.Can you provide sample?

A2: Yes, we can offer sample , and some samples are free

Q3:Can you delivery by express?

A3: Yes, we can delivery by any express

Q4.Can you accept OEM ?

A4: YES! We can according your demand to produce.

Product Picture

Produce Processing

- Q: Expert answer. What is the difference between ceramic fiber paper and ceramic fiber cloth?

- Ceramic fiber cloth is made of heat-resistant gold wire or non alkali glass yarn reinforced spun wire ceramic fiber yarn. The ceramic fiber cloth has high strength, good flexibility and processability. It not only has high temperature insulation property, but also has the flexibility of ordinary textile. Fire retardant clothing, fire blankets, insulation and other industrial and civilian fire insulation products.

- Q: Which is the best insulation effect of ceramic fiber paper and XPE insulation film?

- I used to work in the ceramic fiber factory for two years, and the main contact was fiber. There is not much contact with paper products and so is the understanding of fiber paper.The use of heat insulation material can not be considered temperature, as well as environmental, economic, atmosphere and many other factors to consider.

- Q: Is the slag ball of the ceramic fiber useful?

- According to the technical staff of Ji'nan Huolong thermal ceramics limited liability company, their company production of ceramic fiber paper and ceramic fiber board using slag ball dregs is removed, usually as raw materials into a new round of melting silk is melted again.

- Q: What are the materials for making ceramic fibers?

- In recent years, because of the global energy prices continue to rise, energy saving has become a China national strategy background, than the insulation bricks and other traditional refractory pouring material such as 10-30% ceramic fiber has been more and more widely used in the domestic Chinese, development prospect is very promising. Throw carpet and spray carpet difference

- Q: Can ceramic fibers be spun into fibers, please?

- The utility model can also achieve higher strength by increasing metal wire reinforcement, and finally can be made into products such as yarn, cloth, belt, rope, packing, etc., and the utility model has wide application.

- Q: What are the prospects for ceramic fiber paper and how much investment will be needed?.

- It's a good prospect. I have friends around here who specialize in this. Not much investment.

- Q: What are the features of ceramic fiber gaskets?

- Mifso-11 ceramic fiber gasket is Xin Xing sealing material factory is composed of ceramic fiber products through precise cutting, punching, die stamping process (part of the product after ultra high pressure adhesive bonding) produced.

- Q: How to paste the ceramic fiber paper on the iron plate?

- Not used in high temperature industry, then with double-sided adhesive can be.

- Q: Why doesn't the insulation effect of ceramic fiber compound reflect the insulation board well?

- Tianjin solid composite reflective insulation board, he has one of the biggest advantages of long-term high temperature, the use of chemical stability, and can be used for a long time.

- Q: How high is the temperature resistance of the ceramic fiber gasket?

- Generally divided into standard type and high profile, the standard temperature of 1260 degrees to 1000 degrees of long-term use of high alumina long-term use of 1200 degrees.

Send your message to us

Ceramic Fiber Paper 1260C (2300F) - 1430C (2600F) Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords