High Temperature Refractory Ceramic Fiber Paper 1430C

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The ceramic fiber are manufactured from high purity raw material alumina powder ,silica sand for the high temperature grades and zircon sand is also used. The ceramic mixture is heated in an high temperature electric furnace and the stream of molten material is drawn into fibers by either spinning or blowing .It is produced by advanced “blown” and “spun” processes . It is featured with high temperature resistance and heat insulation and high anti-melt capability, very low thermal conductivity, chemical corrosion resistance and thermal shock stability.Product coverage areas including petrochemical industry, steel industry, aluminum industry, metallurgy industry.

Product Applications:

Ceramic Fiber Bulk are ideal for use in the below applications

Industial thermal insulation and sealing corrosion resistance material, such as industrial furnace and steel pipe or metal casting

Thermal and electiical insulation meterial

Instrument equipment inslution material

Kiln cr deck covering for insulaiton

Product Advantages:

CNBM has success in its ceramic fiber products due to their cost-effectiveness and excellent insulating properties. CNBM also has experience in ceramic fiber blankets application and would like to assist you in product selection, system design, and installation techniques.

Main Product Features:

Low thermal conductivity , low thermal capacity,and excellent thermal insulation property.

High chemical stability ,resistance to corrosion ,excellent eletric insulation property

Good flexibility and toughness,easy to cut or install quickly

Good thermal stability and resistance to thermal shock.

Good sound absorption and mechanism strength

Non-asbestos,low slag ball content

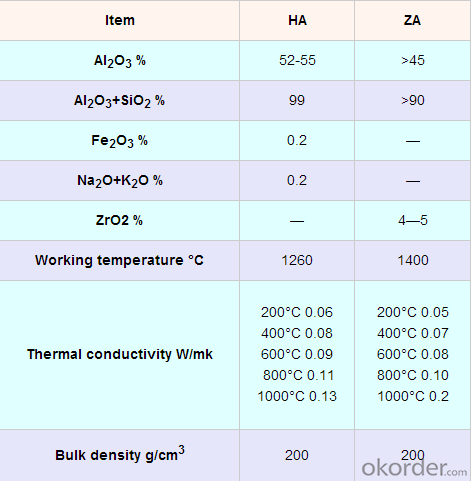

Product Specifications:

FAQ:

Q1.What is your MOQ?

A1 :MOQ may vary by customer's special requirement; we try our best to meet your business requirement.

Q2.Can you provide sample?

A2: Yes, we can offer sample , and some samples are free

Q3:Can you delivery by express?

A3: Yes, we can delivery by any express

Q4.Can you accept OEM ?

A4: YES! We can according your demand to produce.

Product Picture

- Q: Expert answer. What is the difference between ceramic fiber paper and ceramic fiber cloth?

- Ceramic fiber paper is made from high purity ceramic fiber and a small amount of binding agents which are scientifically selected and tightly controlled. The wet vacuum forming process makes the fiber distribution very uniform, and the thickness and volume density of the aluminosilicate fiber paper can be strictly controlled. The binder will be completely ablated during use.

- Q: Is the slag ball of the ceramic fiber useful?

- Slag balls are basically useless, just like raw ore.

- Q: What are the materials for making ceramic fibers?

- The main raw material for the production of ceramic fiber cotton is mainly three two aluminum oxide, and silicon dioxide production process through the silk process, Wuhan, Kyrgyzstan rnd-digital ceramic fiber and ceramic foam with instructions on

- Q: The condition of ceramic glass fiber at high temperature

- Glass and ceramic fibers are inorganic non-metallic materials, they are silicate, can be used as structural materials that emphasize mechanical properties, but also can be used as functional materials that emphasize photoacoustic magnetic properties, but the 1. general glass is amorphous substance, the fibers are formed by melting under drawing while; ceramics is a crystal structure of the fiber by solution or melt into the crystal growth out of course, can also be formed by chemical synthesis or decomposition method;

- Q: How are ceramic fiber papers attached to the interior wall?

- There are two ways to apply ceramic fiber paper to the wall. The first is to buy ceramic fiber paper with single-sided adhesive tape, and the second is to paste it directly with double-sided adhesive tape. From Ji'nan dragon hot ceramics limited liability company, refractory materials chapter

- Q: Do ceramic fiber paper smell at high temperature?

- Ceramic fiber paper is made from high purity ceramic fibers, with a small amount of scientifically selected and tightly controlled binders, and binders will evaporate during use. If the ceramic fiber paper in a high temperature environment, the bond will gradually volatile, volatile initial will have a certain odor, and so volatile, there will be no flavor. The binder is a series of organic rubber, and the smell remains as little as possible.

- Q: Aluminum silicate blanket is used for heat preservation tube or aluminium silicate ceramic fiber paper

- The heat preservation of the pipe is usually made of aluminium silicate fiber blanket. The heat preservation of the base is made of aluminium silicate ceramic fiber paper. The insulation of the pipe is very little.

- Q: Do fiberglass or ceramic fiber paper have insulation effect?

- Second, in the case of temperature can be met, glass fiber cotton insulation better. The main advantage of ceramic fiber is to make gaskets and the like.

- Q: How to paste the ceramic fiber paper on the iron plate?

- Not used in high temperature industry, then with double-sided adhesive can be.

- Q: Why doesn't the insulation effect of ceramic fiber compound reflect the insulation board well?

- And although the ceramic fiber high temperature resistance, but in 1400 degrees when the use of life will be greatly reduced, and the thermal conductivity of the beginning as compound reflection insulation board, high temperature is higher than the compound reflection insulation board greatly.

Send your message to us

High Temperature Refractory Ceramic Fiber Paper 1430C

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords