Ceramic Fiber Paper 1260 Alumina Silicate Heat Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The ceramic fiber are manufactured from high purity raw material alumina powder ,silica sand for the high temperature grades and zircon sand is also used. The ceramic mixture is heated in an high temperature electric furnace and the stream of molten material is drawn into fibers by either spinning or blowing .It is produced by advanced “blown” and “spun” processes .

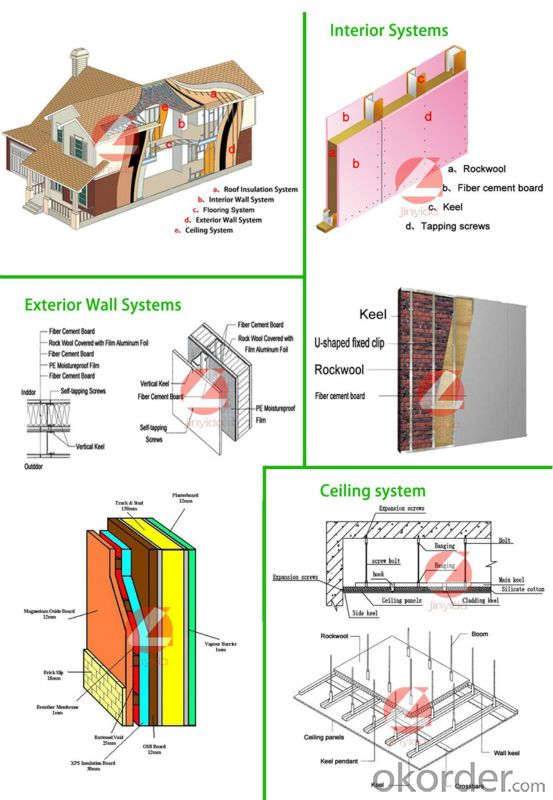

Product Applications:

Ceramic Fiber Bulk are ideal for use in the below applications

The industry kiln, heating device, high temperature pipe lining

Power boiler,gas turbine and heat and nuclear power insulation

Chemical industrial high temperature equipment and heating

equipment lining

Product Advantages:

CNBM has success in its ceramic fiber products due to their cost-effectiveness and excellent insulating properties. CNBM also has experience in ceramic fiber blankets application and would like to assist you in product selection, system design, and installation techniques.

Main Product Features:

•Easy twisting, shaping and cutting

•Excellent machining performance

•Excellent tensile strength

•Acoustic performance

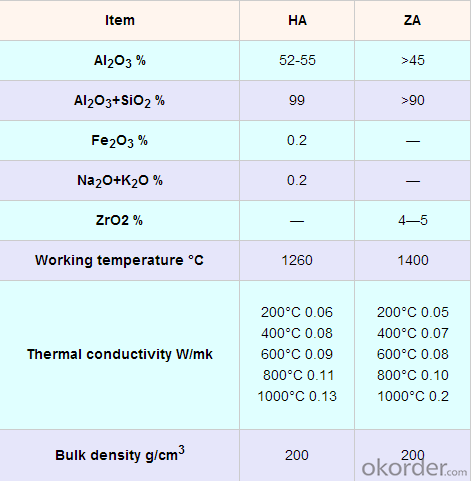

Product Specifications:

FAQ:

Q1.What is your MOQ?

A1 :MOQ may vary by customer's special requirement; we try our best to meet your business requirement.

Q2.Can you provide sample?

A2: Yes, we can offer sample , and some samples are free

Q3:Can you delivery by express?

A3: Yes, we can delivery by any express

Q4.Can you accept OEM ?

A4: YES! We can according your demand to produce.

Product Picture

Produce Processing

- Q: Expert answer. What is the difference between ceramic fiber paper and ceramic fiber cloth?

- Ceramic fiber paper is made from high purity ceramic fiber and a small amount of binding agents which are scientifically selected and tightly controlled. The wet vacuum forming process makes the fiber distribution very uniform, and the thickness and volume density of the aluminosilicate fiber paper can be strictly controlled. The binder will be completely ablated during use.

- Q: Ceramic fiber insulation moisture-proof, but also play a cooling effect?

- Then use the compressed air jet or use the wire throwing machine to turn the yarn into a fiber. After the cotton collector sets the cotton, it forms the ceramic fiber cotton.Fiber cotton can be further processed into fiber blanket, board, paper, cloth, rope and other products.

- Q: Which is the best insulation effect of ceramic fiber paper and XPE insulation film?

- The insulation effect depends on the temperature. The same material, the temperature is different, thermal conductivity is not the same. At low temperatures, I suggest you use XPE. Ceramic fiber paper is generally used for hundreds of degrees or even thousands of degrees of high temperature.

- Q: Is everybody ceramic fiber cotton poisonous?

- No poison, carpet fiber silk if coarse, there is a little prick, make the skin may itch.

- Q: Aluminum silicate blanket is used for heat preservation tube or aluminium silicate ceramic fiber paper

- The stomatal density can know, aluminum silicate fiber blanket rate is much higher than that of aluminium silicate ceramic fiber paper, because the aluminum silicate fiber blanket belongs to pure inorganic products, and the pipe wall fits more closely, so the aluminum silicate fiber blanket thermal insulation on the pipeline used in large quantity, because the aluminum silicate ceramic fiber paper with organic ingredients, better insulation aluminum silicate fiber blanket. If you have a large number of pipes to do heat preservation, you can refer to the following fire pipe insulation thickness selection experience table.

- Q: What are the features of ceramic fiber gaskets?

- 1) the continuous use temperature can reach 1000 DEG C, and the service temperature can reach 1260 DEG C for a short time.2) has good acid and alkali corrosion resistance and aluminum, zinc and other molten metal melting ability.3) good high temperature strength and heat insulation performance (refer to physical and chemical indexes).4) having a higher level of electrical insulation and high temperature electrical insulation than glass fibers.5) non-toxic, harmless and odorless.

- Q: What fiber glass made of ceramic fiber paper?

- Ceramic fiber paper production process is:Beat out - pulp - pulp - long mesh forming - vacuum dehydration - drying - cutting - winding - packaging

- Q: Carbon fiber and aluminum alloy material in the end what is the difference?

- Aluminum alloy advantages: air oxidation resistance, cost-effective, easy to manufacture. The disadvantage is that the elasticity is poor and the strength is low.

- Q: Why doesn't the insulation effect of ceramic fiber compound reflect the insulation board well?

- And although the ceramic fiber high temperature resistance, but in 1400 degrees when the use of life will be greatly reduced, and the thermal conductivity of the beginning as compound reflection insulation board, high temperature is higher than the compound reflection insulation board greatly.

- Q: How high is the temperature resistance of the ceramic fiber gasket?

- Generally divided into standard type and high profile, the standard temperature of 1260 degrees to 1000 degrees of long-term use of high alumina long-term use of 1200 degrees.

Send your message to us

Ceramic Fiber Paper 1260 Alumina Silicate Heat Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords