High Purity Ceramic Fiber Paper Blanket 1260 for Heating Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 8000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

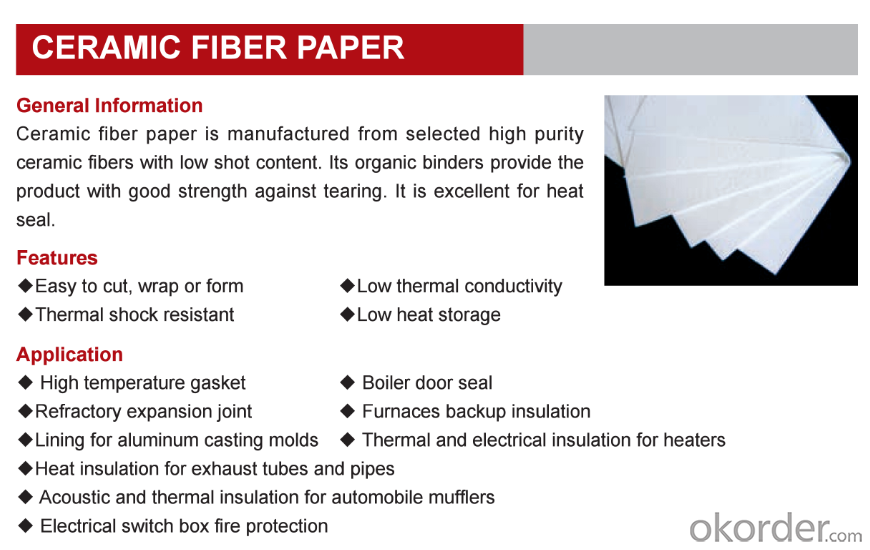

Features of ceramic fiber flexible heat refractory paper

1.light weight

2.easy to install

3.Low thermal conductivity

4.good electric insulation

5.excellent corrosion resistant

6.Free of asbesto

Application range of ceramic fiber flexible heat refractory paper

1.Industrial material for thermal insulation ,sealing and corrosion prevention.Such as high temperature thermal insulation material for industrial furnace and steel ladle, seal material for furnace expansion joints, insulation for the glass products.

2.Thermal and electrical insulation material for electric heating device. Such as industrial electrical furnace.

3.Electrical and thermal insulation material for instrument equipment and heating element, like seal the lining of the cast aluminum model.

4.Heat insulation material for auto industry, such as auto exhaust pipe.

Technical data of ceramic fiber flexible heat refractory paper

Classification Temperature(°C) | 1260 | 1450 | ||

Working Temperature(°C) | 1200 | 1400 | ||

Chemical Composition (%) | AL2O3 | 47 | 38 | |

SiO2 | 51 | 44 | ||

Fe2O3+Ti2O3 | ≤0.3 | ≤0.2 | ||

CaO+MgO | ≤0.3 | ≤0.2 | ||

Na2O+KO2 | ≤0.3 | ≤0.2 | ||

Density (kg/m3) | 180-220 | |||

Common Size | Length×Width ×thickness 60,000×610/1220×1mm 30,000×610/1220×2mm 20,000×610/1220×3mm 15,000×610/1220×4mm 12,000×610/1220×5mm 10,000×610/1220×6mm | |||

- Q: Are ceramic fiber paper permeable?

- Ceramic fiber paper is said to be paper, in fact, is relatively large density, but still cotton like, it is permeableCeramic fiber composite board is able to play a certain waterproof effect

- Q: Expert answer. What is the difference between ceramic fiber paper and ceramic fiber cloth?

- Ceramic fiber cloth is made of heat-resistant gold wire or non alkali glass yarn reinforced spun wire ceramic fiber yarn. The ceramic fiber cloth has high strength, good flexibility and processability. It not only has high temperature insulation property, but also has the flexibility of ordinary textile. Fire retardant clothing, fire blankets, insulation and other industrial and civilian fire insulation products.

- Q: Which insulation effect is better compared with ceramic fiber for STP insulation board?

- But the use of different temperature, nano microporous insulation materials used in 1000 DEG, 1600 DEG C high temperature resistant ceramic fiber.

- Q: How are ceramic fiber papers attached to the interior wall?

- Ceramic fiber paper afraid of water, and no adhesion, putty powder is difficult to hang, it is almost impossible to wallpaper, ceramic fiber paper with ceramic fiber mortar by vacuum filtration process, the surface will remain part of the fiber powder, suggest that you make ceramic fiber paper on the walls of the inner layer. From Ji'nan dragon hot ceramics limited liability company, refractory materials chapter.

- Q: Do ceramic fiber paper smell at high temperature?

- Ceramic fiber paper is made from high purity ceramic fibers, with a small amount of scientifically selected and tightly controlled binders, and binders will evaporate during use. If the ceramic fiber paper in a high temperature environment, the bond will gradually volatile, volatile initial will have a certain odor, and so volatile, there will be no flavor. The binder is a series of organic rubber, and the smell remains as little as possible.

- Q: Where is the best packing area for ceramic fibers?

- As the temperature continues to rise, the products will gradually become white, organic fiber has been completely carbonized products completely for the high temperature inorganic ceramic fiber resistant ceramic fiber (standard type) white maximum temperature ceramic fiber cloth content index color 1260 C fiber diameter 1-4 m thermal shrinkage (1232 C, 24h) 3.5% transmission rate (at 538 8pcf) three 0.130w/m.k two aluminum oxide content 45-48% 0.7-1.2% ferric oxide content of calcium oxide and sodium oxide content of 0.43% slag ball content <8.5% breakdown voltage 5 kv/mm resistance of 5 * 1010 ohm 3w.xxceramic content index white color thickness 1.5mm--6.0mm single 0.5 3kg/ square meters of organic fiber content <20% content <2% strengthening materials alkali glass fiber nichrome wire (1Cr18Ni9Ti)

- Q: What is ceramic fiber paper? What is ceramic fiber paper for?

- In order to understand what ceramic fiber paper can do, it is necessary to know what product characteristics it has. Only by knowing these advantages can we make accurate judgments about what we can do.The ceramic fiber paper is made of ceramic fiber, so the ceramic fiber paper itself contains no asbestos and can replace the carcinogenic asbestos products on the market.The raw material of the ceramic fiber paper is longer, low density, high strength, and has a certain elasticity, so it is easy to carry out stamping, cutting, winding and other construction operations. It is because of the ceramic fiber paper after high temperature firing process, so it has high temperature resistance, chemical corrosion, thermal shock, low thermal conductivity, good dielectric strength and high elastic modulus and high performance.

- Q: What are the prospects for ceramic fiber paper and how much investment will be needed?.

- In recent years, due to the global energy prices continue to rise, energy saving has become a China national strategy background, than the insulation bricks and other traditional refractory pouring material such as 10-30% ceramic fiber has been used more widely in the domestic more Chinese, development prospects are very promising.

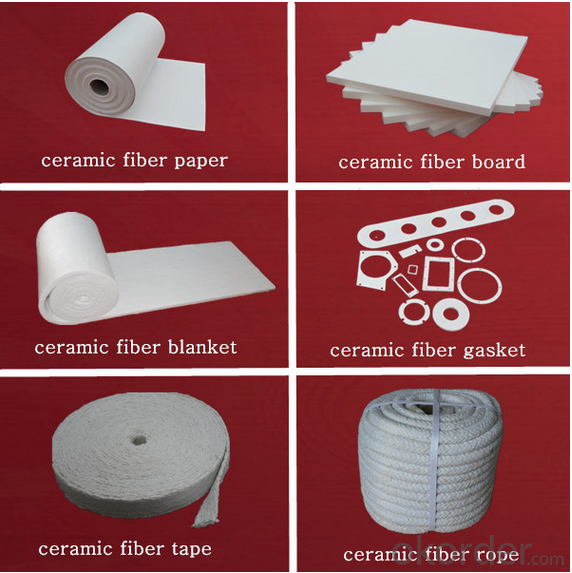

- Q: What are the features of ceramic fiber gaskets?

- 1) the continuous use temperature can reach 1000 DEG C, and the service temperature can reach 1260 DEG C for a short time.2) has good acid and alkali corrosion resistance and aluminum, zinc and other molten metal melting ability.3) good high temperature strength and heat insulation performance (refer to physical and chemical indexes).4) having a higher level of electrical insulation and high temperature electrical insulation than glass fibers.5) non-toxic, harmless and odorless.

- Q: How high is the temperature resistance of the ceramic fiber gasket?

- Ceramic fiber gasket to see what you are using material, usually refers to ceramic fiber paper made of high temperature gasket

Send your message to us

High Purity Ceramic Fiber Paper Blanket 1260 for Heating Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 8000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords