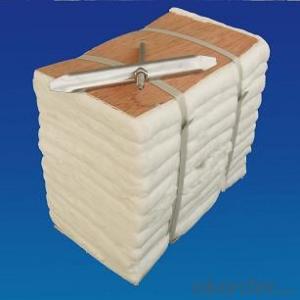

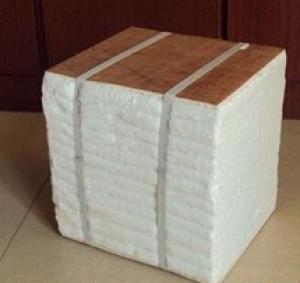

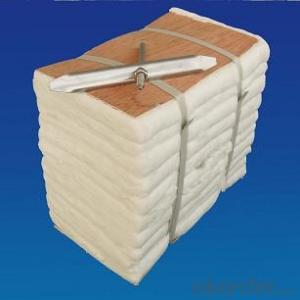

Ceramic Fiber Module Refractory Anchor Product

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Material: SS310,SS304

Ingredient: 1Cr18Ni9Ti, Cr25Ni20

Working temperature 1260/1400 °C

For installation of ceramic fibre modules and block

U-form penetration nail

Instant card, rotation card

penetration rod

screw, nut

v-form rame

angle iron anchor

butterfly anchor

diamond anchor

hole suspending anchor, corner, anchor,etc

Wide temperature range,from800C to 1400C

Various shapes

Reasonable structure

Firm, reliable anchor

Install easily and quickly

Type | Anchor Products | |

Classification Temp.(°C) | 1260 | 1400 |

Name/Type | U-form penetration nail, Instant card, rotation card, penetration rod, screw, nut v-form rame, angle iron anchor, butterfly anchor, diamond anchor, hole suspending anchor, corner, anchor,etc | |

Textures | 304S Series | 310S Series |

Working Temp. (°C) | 1260 | 1430 |

Size | The anchor can be designed according to the application and the size of modules. | |

Packing | Carton | |

Technical Criteria | 1Cr18Ni9Ti | Cr25Ni20 |

- Q: Can stainless steel wire be used for automotive springs?

- Yes, stainless steel wire can be used for automotive springs. Stainless steel has excellent corrosion resistance and high tensile strength, making it a suitable material for springs that are exposed to harsh environments or require high durability.

- Q: Can stainless steel wire mesh trays be used for baking?

- Yes, stainless steel wire mesh trays can be used for baking. Stainless steel is a durable and heat-resistant material that can withstand high temperatures, making it suitable for baking purposes. The wire mesh design allows for proper heat circulation, resulting in even baking and browning of the food. The trays are also non-stick, which makes them easy to clean and prevents food from sticking to the surface. Additionally, stainless steel is a non-reactive material, meaning it does not interact with acidic or alkaline ingredients, ensuring that the taste and quality of the baked goods remain intact. Thus, stainless steel wire mesh trays are an excellent choice for baking various items such as cookies, pastries, bread, and more.

- Q: What are the different types of stainless steel wire brushes?

- There are several different types of stainless steel wire brushes available, each designed for specific applications and purposes. Some of the most common types include: 1. Crimped wire brushes: These brushes have a crimped wire pattern, which helps to increase the flexibility and surface coverage. They are commonly used for light to medium-duty cleaning and deburring tasks. 2. Knotted wire brushes: These brushes have wire knots that are twisted together, providing a more aggressive brushing action. They are ideal for heavy-duty tasks such as removing rust, weld scale, and corrosion from metal surfaces. 3. Cup brushes: Cup brushes have a cylindrical shape with bristles arranged in a cup-like configuration. They are typically used for cleaning large flat surfaces, such as removing paint or rust from metal parts. 4. Wheel brushes: Wheel brushes are similar to cup brushes but have a wheel-shaped design. They are often used for cleaning and finishing applications on curved or irregular surfaces. 5. End brushes: End brushes have bristles arranged in a circular pattern at the end of the brush. They are commonly used for reaching tight or hard-to-reach areas, such as cleaning threads, grooves, or crevices. 6. Miniature brushes: These brushes are small in size and are often used for precision cleaning or detailing work. They are commonly used in industries like jewelry making, electronics, or dental applications. 7. Strip brushes: Strip brushes consist of a strip of stainless steel wire bristles held together by a metal or plastic backing. They are frequently used for industrial applications, such as sealing gaps, dust or debris removal, or conveyor belt cleaning. Each type of stainless steel wire brush has its own unique characteristics and applications, so it's important to choose the right brush for the specific task at hand.

- Q: What are the different types of stainless steel wire rope terminations available?

- Different types of stainless steel wire rope terminations are available, each with its own advantages and suitability for various applications. Some commonly used types include: 1. Wire Rope Clips, also known as wire rope clamps, consist of a U-bolt, saddle, and nuts. They offer an easy installation process and create a strong and secure connection. These terminations are typically used for applications that require light to medium-duty usage. 2. Swage Fittings involve permanently attaching a fitting to the wire rope by compressing it with specialized tools. This method ensures a clean and streamlined termination, providing excellent strength and durability. Swage fittings are commonly used in heavy-duty applications and critical load-bearing situations. 3. Thimbles are metal sleeves inserted into the eye or loop of the wire rope to protect it from abrasion and wear. They help maintain the rope's shape and increase its longevity. Thimbles can be used in combination with wire rope clips or swage fittings to provide additional reinforcement. 4. Turnbuckles are adjustable fittings consisting of two threaded eye bolts connected by a metal body. They enable easy tensioning and adjustment of the wire rope, making them ideal for applications that require periodic tightening or fine-tuning. 5. Nicopress Sleeves, also known as compression sleeves, are made of aluminum or copper and are used in conjunction with a special tool to compress and secure the wire rope. They offer a reliable termination option for light to medium-duty applications and are commonly used in marine and architectural settings. To ensure the appropriate termination is selected for your application, it is crucial to consider specific requirements such as load capacity, environmental conditions, and desired level of permanence. Seeking advice from a knowledgeable supplier or engineer can help ensure the right choice for your stainless steel wire rope termination needs.

- Q: Can stainless steel wire be coated for additional protection?

- Stainless steel wire has the ability to be coated in order to provide additional protection. By coating stainless steel wire, an extra layer of protection is added to prevent corrosion, wear, and other environmental factors from compromising its durability. There are several methods available to apply the coating, including electroplating, powder coating, and chemical coatings. These coatings not only improve the wire's resistance to rust and other forms of corrosion, but they also enhance its appearance and make it easier to handle and work with. In some cases, certain coatings can even provide insulation or enhance the wire's heat resistance, allowing it to be used in specific applications. Overall, coating stainless steel wire is a widely practiced technique in various industries and applications to enhance its protective properties and extend its lifespan.

- Q: Can stainless steel wire be used for woven wire cloth?

- Yes, stainless steel wire can be used for woven wire cloth. Stainless steel wire is commonly used in the production of woven wire cloth due to its durability, resistance to corrosion, and high tensile strength. It is an ideal material for applications that require a strong and long-lasting wire cloth, such as filtration, sieving, and separation processes. Stainless steel wire can be woven into various mesh sizes and patterns to suit specific requirements, making it a versatile choice for many industrial and commercial applications.

- Q: Can stainless steel wire be used for springs in the electronics industry?

- Indeed, springs in the electronics industry can make use of stainless steel wire. The outstanding corrosion resistance, impressive strength, and commendable elasticity of stainless steel make it a favored option for springs. These characteristics render stainless steel wire suitable for a multitude of applications in the electronics sector, encompassing connectors, switches, relays, and other electronic components that necessitate dependable and long-lasting springs. Moreover, stainless steel springs exhibit the ability to endure high temperatures and possess commendable electrical conductivity, thereby making them an optimal choice for incorporation in electronic devices.

- Q: Is stainless steel wire resistant to chemicals?

- Yes, stainless steel wire is generally resistant to chemicals. Stainless steel is known for its corrosion-resistant properties, which make it highly resistant to various chemicals. It has a high resistance to acids, alkalis, solvents, and other chemical substances, making it suitable for use in environments where exposure to chemicals is common. However, it is important to note that the level of resistance may vary depending on the specific grade and composition of the stainless steel wire. Additionally, prolonged exposure to certain aggressive chemicals or extreme conditions may still cause some corrosion or damage. Therefore, it is recommended to consult the manufacturer or supplier for specific information on the resistance of stainless steel wire to the chemicals you intend to use it with.

- Q: Stainless steel tapping easily broken wire attack, how to do?

- In tapping, to tap with people's daily consumption of vinegar, tapping the silk will be quite a lot. In addition, if the tap is not too sharp, do not use it reluctantly, so it is easy to break tap.

- Q: What are the different types of stainless steel wire ropes used in aerospace industries?

- There are several different types of stainless steel wire ropes that are commonly used in aerospace industries. These wire ropes are specifically designed to meet the stringent requirements and standards of the aerospace sector. Some of the different types include: 1. 1x19 Stainless Steel Wire Rope: This type of wire rope consists of 19 individual strands, each consisting of a single wire. It offers high tensile strength and excellent resistance to corrosion, making it suitable for various aerospace applications such as control cables and suspension systems. 2. 7x7 Stainless Steel Wire Rope: This wire rope is constructed with seven strands, each consisting of seven wires. It provides good flexibility and durability, making it ideal for applications that require repetitive bending and twisting motions, such as aircraft control cables and safety harnesses. 3. 7x19 Stainless Steel Wire Rope: With seven strands, each containing 19 wires, this wire rope offers a balance between flexibility and strength. It is commonly used in aerospace industries for applications such as lifting and rigging, as well as for aircraft control cables and suspension systems. 4. 6x19 Stainless Steel Wire Rope: This wire rope consists of six strands, each containing 19 wires. It provides excellent flexibility and fatigue resistance, making it suitable for applications that require repeated bending and twisting, such as overhead crane systems and cargo handling equipment in aircraft. 5. 6x36 Stainless Steel Wire Rope: This type of wire rope is constructed with six strands, each containing 36 wires. It offers high strength and flexibility, making it ideal for heavy-duty applications in aerospace industries, such as aircraft landing gear cables and winch systems. These are just a few examples of the different types of stainless steel wire ropes used in aerospace industries. Each type is selected based on the specific requirements of the application, including load capacity, flexibility, and resistance to corrosion. The aerospace industry relies on these specialized wire ropes to ensure the safety and reliability of various aircraft components and systems.

Send your message to us

Ceramic Fiber Module Refractory Anchor Product

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords