Ceramic Fiber Bulk for Heat Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Ceramic fiber bulk is made of coal gangue by melting at high temperature through

resistance furnace, before being blown or spun into fiber.

As a neutral and acidic material, except reaction with the strong acid-alkali, ceramic fiber won’t

be eroded by other weak alkali, weak acids, or water, oil, steam, or be infiltrated with lead,

aluminum or copper, featuring excellent flexibility and elasticity,also lightweight,heat insulation,

low thermal conductivity etc.

Ceramic fiber bulk application

(1)Raw material for fiber blanket, board products; Raw material for fiber textile products;

(2) Joint sealing and filling insulation for industrial kilns and fuming channel and high temperature pipes

(3) Raw material wet processed products;

(4) Fiber spraying;

(5) Raw material for coatings and castables;

(6) Insulation fillings for corner and complex space.

Specifications

Refractory ceramic bulk

Low thermal conductivity

Excellent thermal stability

Excellent sound absorption

DATA SHEET

CERAMIC FIBER BULK-STD | |

Classification Temperature(℃) | 1260 |

Working Temperature (℃) | 1050 |

Melting Point ( ) ℃ | 1600 |

Color | White |

Short Content (%) | <15< span=""> |

Chemical Composition (%) | |

Al2O3 | 45-47 |

Al2O3+ SiO2 | 98.5 |

Fe2O3 | <0.4< span=""> |

K2O+Na2O | <0.3< span=""> |

CaO + MgO | <0.2< span=""> |

Note: Technical Data are typical results from test pieces. This information, subject to change, is offered solely for your consideration. Users of our products should make their own tests to determine the suitability of each product for their particular purposes

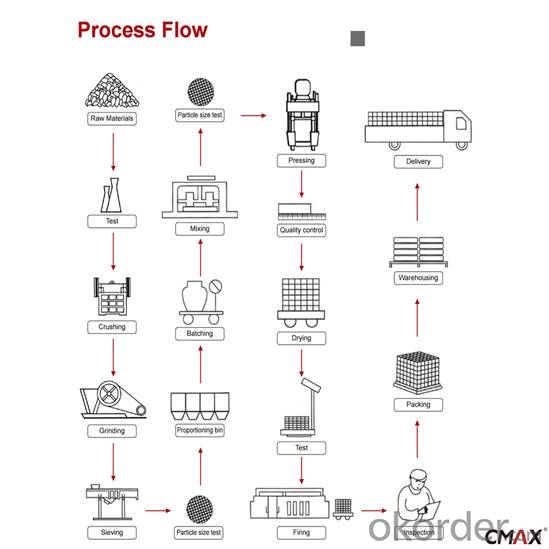

Packaging & Delivery

Packaging Details: Wrapped by plastic bag and then put into carton box designed for export.

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research, development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection, supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc. If any question, please contact us freely.

- Q: What are the main differences between an ordinary furnace and a ceramic fiber furnace?

- The main difference between ordinary furnace and ceramic fiber furnace:Refractory, heat insulation: ceramic fiber furnace low thermal conductivity, low thermal conductivity, is a better thermal insulation materials, the use of temperature within one thousand and three hundred Baidu. The heat conductivity of common furnace is higher and the heat loss is great

- Q: What is the density of ceramic fiber modules? The best insulation effect

- Ceramic fiber module density is only a standard in the world, is 220Kg/m fand, but in the actual application, according to the heat treatment furnace, furnace temperature, combustion medium, temperature rise requirement of ceramic fiber module density in 200-240Kg/m fand, ceramic fiber blanket, because the processing of ceramic fiber module uses double roller today advanced technology and technology of silk, fiber length of the ceramic fiber blanket which produced in 80-130 mm, so the maximum density of the ceramic fiber module is more than the density, 240Kg/m fand, a large amount of fiber fracture, the fracture rate is as high as 48%. So after the actual verification at home and abroad of tens of thousands of industrial furnaces, the best density of ceramic fiber module is fand 220Kg/m.

- Q: Should the ceramic fiber furnace be compacted?

- In view of the large industrial furnace, the ceramic fiber module can be chosen to be refractory, heat insulated and insulated, and the ceramic fiber module is firmly fixed on the furnace wall by the parallel mounting method, which is more reliable

- Q: What is the difference between the ceramic fiber cloth and the high silicon oxygen cloth?

- High temperature is similar to that of strength, service life, the price is high silica cloth. High silica fabric belongs to glass fiber.

- Q: Glass fiber cotton, aluminum silicate cotton, rock wool, what's the difference between these three?

- Three kinds of materials are heat insulation materials, applications and temperature resistance is different.Glass fiber cotton is a kind of excellent performance of inorganic non-metallic materials, variety, has the advantages of good insulation, strong heat resistance, good corrosion resistance, high mechanical strength, but the disadvantage is brittle, poor wear resistance, the maximum temperature of four less than Baidu.

- Q: What is the diameter of the ceramic fiber? How to mix?

- Fiber diameter: rejection fiber more coarse, rejection fiber generally 3.0-5.0 - m, spinneret fiber is generally 2.0-3.0 - m;

- Q: Is aluminum silicate fiber poisonous?

- Then use the compressed air jet or use the wire throwing machine to turn the yarn into a fiber. After the cotton collector sets the cotton, it forms the ceramic fiber cotton. In the whole process of production, it can be found that the raw material does not contain toxic substances. Compared with asbestos, it is a substitute product of asbestos and contains no carcinogens.

- Q: The difference between the ceramic fiber blanket and rock cotton blanket

- The heat capacity (heat storage capacity) of ceramic fiber lining is low: the heat capacity of ceramic fiber is only about l/10 of light heat resistant lining and light castable lining, and the heat capacity of lining material is proportional to the weight of lining. Low heat capacity means the furnace in the reciprocating operation absorb less heat and heating speed, greatly reducing the operational control of the temperature in energy consumption, especially for heating furnace and furnace, furnace shutdown has obvious energy saving effect.

- Q: Aluminum silicate needle carpet and ceramic fiber insulation performance of the good

- Aluminosilicate ceramic fiber has two different production processes, respectively, the rejection process and the blowing process. The carpet produced by the spinning process has long fiber length, high tensile strength and wide range of use. The blanket produced by blowing process is short in length and easy to break, and the scope of application is relatively narrow.

- Q: Ceramic fiber material fire shutter door how many square?

- There is no full ceramic fiber material fire shutter;

Send your message to us

Ceramic Fiber Bulk for Heat Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords