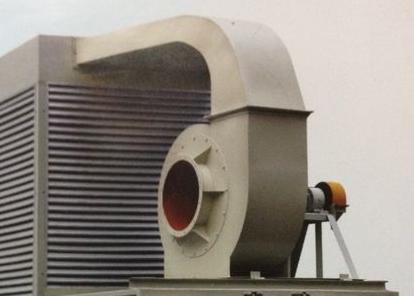

Centralized Wood Working Dust Collector MF90280

- Loading Port:

- Shunde, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 10000pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction Of Centralized Wood Working Dust Collector MF90280

1. This machine is most suitable to be installed in a small and medium size workshop. This machine can handle the paring, sawdust, sanding dust and other flotsam from 15 to 20 working points all at the same time in a centralized way, this machine can effectively absorb the flow of dusts, and directly blow it into the sealed tank, and then drain the filtered air flow out of dusts. After all, with the help of this machine, you have more working space and much cleaner environment.

2. Compared with the traditional one machine one dust collector combination method, the machine can save quite a some working space and costs in installing the costly centralized turbo collecting system.

3. Compared with the big centralized dust collector, this machine can be used in the room. When the workshop has central heating in the cold area, it can avoid to blow a great lot of the central heating, so it can reduce the cost and save the energy.

Technical Data Of Centralized Wood Working Dust Collector MF90280

Engine motor power 15kw

Rotation speed 1520 r/min

Air delivery 28258 m³/h

Air pressure 1320 pa

Inlet size Φ 550mm

Collection tank 15m³

Filter bag Φ15*180cm*110pcs

Overall size 430*220*410cm

Net weight 1670kg

Factory Details Of Centralized Wood Working Dust Collector MF90280

- Q: What are the categories of woodworking dust removal?

- The other one is in addition to paint mist, this is a little complex, because he not only to remove the paint mist dust, will smell removed, otherwise the EPA does not agree. This system has two parts, one is the dust catcher, must pulse bag, bag for special materials, not easy to be viscous paint mist that is, the two character absorption tower, to smell special, after two step treatment, clean air can be discharged arbitrarily. On the outward to smell there is still a kind of infrared heating technology, I think the technology is not mature, not Luanjiang, you can check, the best site visits.

- Q: How to determine the diameter of the suction port of the dust removal system?

- There should be no specific criteria for selecting the suction port diameter, which requires long product production times or specific tests. But according to the specific work environment, determine the dust removal system fan, according to customer demand, wind speed or ventilation, work environment or space choice.

- Q: What kind of dust collector is used in a furniture factory or a woodworking factory?

- Powerful furniture factories are set up a central vacuum cleaner, a full set of equipment down millions, mainly after the high electricity tariffs, because the power is very large, and some factories according to the rise, but can not afford.

- Q: What problems should be paid attention to during the operation of woodworking bag filter?

- Then check the mechanical components to see if the intake, exhaust and bypass valves can be fully opened, tightly closed, locked, and verified to indicate the limit switch. The ash conveying machine shall be checked for proper operation. Guan fly filter Co., Ltd., cement warehouse top dust collector, mixing station, warehouse top dust collector, professional manufacturers. Please feel free to buy. Damage in transit. Our company will re organize shipment. Unrelated to the consignee.

- Q: What kinds of dust collector can be used for dust removal in woodworking?

- Two suction tower, special to smell, and after two steps, the clean air can be arbitrarily discharged. About to smell there is still a kind of infrared heating technology, I think the technology is not mature, not Luanjiang, you can check, the best on-the-spot investigation. Power consumption depends mainly on your air volume or handling capacity, large air flow, power increases naturally. A key issue here is to the pipeline design and make scientific and reasonable, to minimize the resistance, reduce the pressure head of fan fan, so that it can reduce the useless work and play an important role in energy-saving.

- Q: How to choose dust collecting fan in woodworking room?

- First of all, find a professional woodworking central dust removal equipment company, providing the layout of the plant, mechanical placement and tuyere diameter

- Q: How to remove the dust produced in the furniture workshop? What dust remover is better?

- The biggest highlights of the sub chamber pulse dust collector in woodworking are: the new optimization of the system structure, the simplified control system improvement, the comprehensive strengthening of energy-saving and low-noise, and the optimized layout of the dust collecting pipe network. The new product line of woodworking dust catcher just meets the demand of wood manufacturer for input, operation and maintenance. Reasonable structure, concise control, for workshop workers, is more conducive to operation and use. Let workers worry, let management worry, let business owners worry. The newest carpentry factory cloth bag dust remover applies in Shandong and Langfang area, has obtained the user approval.

- Q: Woodworking dust removal centrifugal or axial flow of good?

- Because dust woodworking equipment is needed in connection with the pipe, dust collector, dust containing air travel in the pipe and pipe wall friction resistance, and the dust collector structure will also have 500-800Pa resistance, so in order to overcome this resistance, requires the fan to generate sufficient pressure to overcome the resistance that is to ensure the absolute flow pressure means.

- Q: What are the principles and operation considerations of woodworking dust collector?

- The process involves drying machine, pressure vent, boiler, hammer mill and wood camber machine operation, there are many variables, such as temperature or humidity is high, and very high dust concentration. Na Lu Xiamen environmental protection.

- Q: What should we pay attention to when we use the woodworking bag dust collector?

- Check the operation of the pulse valve regularly, whether or not the valve is leaking.

1. Manufacturer Overview

| Location | Foshan, China |

| Year Established | 2006 |

| Annual Output Value | Above US$ 100 Million |

| Main Markets | European Coutries; Southeast Countries; Russia Federation; Brazil; Peru; Chile; China |

| Company Certifications | ISO9001; CE |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Rongqi; Beijiao; Huangpu; Shenzhen |

| Export Percentage | 80% |

| No.of Employees in Trade Department | 100-501 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 220,000 square foot production plant |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Centralized Wood Working Dust Collector MF90280

- Loading Port:

- Shunde, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 10000pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords