Polyimide Non Woven dust Bag Filters for power cement plant

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

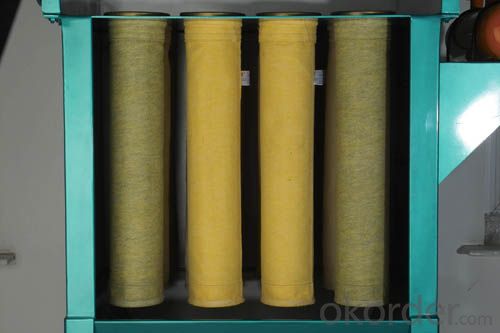

Polyimide Non Woven Bag Filters

Overview:

Our company can supple all kinds of Polyimide non woven bag filters.

Duo to the irregular cross section, the specific surface area of the fiber is relatively large, thus it has relatively good dust catching capability, its catching capability for ultra fine dust is higher than other fiber.

The quality of the filter bag determines the result of filtration to a great extent. Our company follows strict standards in sourcing raw materials and in the manufacturing process of all filter bags to ensure that they are 100% good quality. The polyimide fiber of tianyu filter bag is selected from world-famous enterprises

Application: cement, coal burning boiler, concrete mixing, waste incineration industry.

Features:

High tensile strength

High abrasive resistance

Easy for cleaning

High precision of filtration

Good air permeability

Good chemical corrosion resistance

Good thermal resistance

Long service life

We pursue quality products, reasonable price and excellent service.

When you choose to use the products of our company, you only need to call or write to the company, we will solve all you troubles and give you a satisfactory results.

Specification:

Material | 100% Polyimide |

Weight | 550±30g/m2 |

Air Perm | 160-240L/m²S |

Warp Tensile Strength | >800N/5×500px |

Weft Tensile Strength | >800N/5×500px |

Warp Elongation | <35%< span=""> |

Weft Elongation | <45%< span=""> |

Continuous Temperature | 230℃ |

Surge Temperature | 250℃ |

Moist Temperature | 195℃ |

Finishing | Singed, smooth , stabilization |

Chemical Resistance: | Acid good |

Alkalis fair | |

Oxidizing Agents good |

Polyimide media may be attacked by moist heat hydrolysis, strong acids, or strong alkalis. The PTFE scrim enhances the media integrity in these conditions. To avoid such occurrences, please operate in an environment in according with the above recommendations.

- Q: Mass production process, equipment and budget for industrial calcium chloride

- Zinc Oxide calcium chloride as main material composite mineralizer, and 600 to 1500 DEG C / min heating rate series combustion method to produce cement clinker. The composite mineralizer content generally between 1-7% (weight percentage). The use of the invention can be in high quality of Portland cement clinker burning is lower than 1000-1250 DEG C and low energy consumption.

- Q: Introduction of iron and manganese filter

- The device uses the aeration oxidation, iron and manganese and manganese sand principle catalysis, adsorption and filtration

- Q: The reason for the great pressure difference of the mechanical filter

- . The function of filtration is to remove suspended or colloidal impurities in water, especially to remove micro particles and bacteria that can not be removed by precipitation technology. BODs and COD also have some degree of removal effect.

- Q: How to choose air filter

- The purification effect of four, the workshop is influenced by the type of air inlet and outlet of the air filter: 360 degree circular design, also has a one-way inlet and outlet air, if not by restrictions on products placed on the pattern of a room, you should choose different import wind design products, mainly have two kinds, including the development of air HEPA filter and ordinary HEPA tuyere.

- Q: Could you tell me how to make the filter, and mine is also very delicious and urgent. Thank you

- he smell is mainly activated carbon filtration, but before it to filter out dust or activated carbon will soon be buried on the dust.. by two or three layers, a layer of coarse filter with acrylic foam

- Q: What are the imported brands, industrial filters and filter elements?. Both Chinese and English are best written. Thank you very much!

- , models, sizes, brands, if not listed on what brand equipment,

- Q: Do you have to drink alcohol for industrial power purification and filtration equipment?

- This depends on how you leaders, and occasionally go,

- Q: Method for treating manganese sand filter

- And used in the swimming pool circulation treatment system, cooling circulating water purification system and so on.

- Q: How is the flow rate of an industrial automatic water filter calculated?

- The filter screen is made of 3-6mm stainless steel sheet, and the core shall be able to withstand the differential pressure of 150 kPa without deformation or damage.

- Q: How to calculate the air volume required for industrial oil mist filters?

- In order to cover the closed machine (a machine only kept opening up and down material) for example,

Send your message to us

Polyimide Non Woven dust Bag Filters for power cement plant

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords