Casting Manhole Cover Double with Customized Seal

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 110 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

1) Designs: based on EN124 standard and according to customer's drawing or

samples.

2) Applications: water supply and drainage, fire engineering, natural

3) Inspection: in-house or the third party as per customer's request.

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than.

Contain no metal and no recovery value, anti-theft.

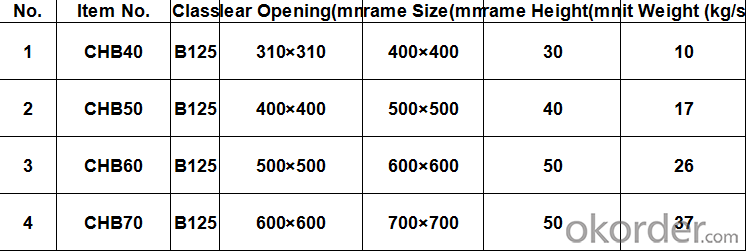

Specifications

Packaging and Shipping

Delivery Detail: 8 days if your order is 20"container

Packaging: Details Pallet with bubble film, Carton or with pallet

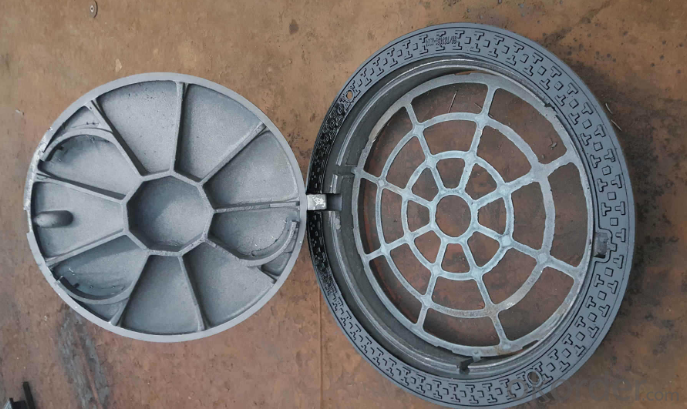

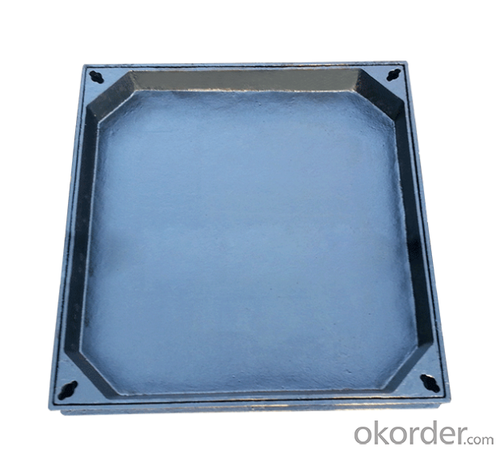

Pictures

Our Company

We take pride to introduce ourselves as the leading manufacturer and professional supplier of various Ductile Iron Manhole covers in China with total annual capacity 50,000 MT.

CNBM manhole cover regard quality as the essential factor leading to successful business. After years of efforts, CNBM manhole cover have built up great reputation in terms of quality and service among domestic and overseas customers.

Our Services

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Professional technical support with free charge.

5. After the cooperation: Any of your problem will be solved within 24 hours.

FAQ

1. How about your price?

A: As one of famous manufacturers of Ductile iron products inChina, Our prices are very favorable and competitive. The customers from all-over the world.

2. Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your requirement, but it maybe let your purchasing cost changed also.

3. Could you specially design and produce for clients?

A: Of course, we have all kinds of professional engineers. We can design and produce special products according to customers' requirements. Such as: special size, special control, OEM, etc.

- Q: What are the factors affecting the machining process of the casting material and structure?

- Medium carbon steel begins, and the casting can not be punched and tapped directlyStainless steel, ordinary grade (Fe based alloy element content, less) can not do heat treatment. But processing small holes or tapping to heat treatment (solution. In practice, the annealing treatment can also be). There are a lot of stainless steel matrix is not to say, for example, nickel, cobalt and tungsten. And so on.

- Q: How do casting parts remove stress?

- Annealing treatment, according to different casting annealing treatment, eliminate thermal stress, if need to restore hardness or increase hardness, and then quenching treatment

- Q: The difference between cement sand castings, resin sand castings and vacuum casting parts

- Vacuum casting is the process of using ventilation molds. Molten metal flows into the mold by air pressure, and then removes air to form a vacuum. The casting process is mainly used for small parts or jewelry with exquisite detailsCompared with the traditional clay sand casting, heat hardening resin sand casting production with low surface roughness, high precision, good quality characteristics, dimensional accuracy of resin sand mold after hardening with good rigidity and high, and not easy to deform, so in the choice of process parameters, mechanical processing you can select a smaller margin, thereby reducing the consumption of metal solution and machining cost, which can improve the dimensional accuracy of castings.

- Q: What should I pay attention to when designing a casting structure?

- (2) in the prevention of metal mold casting misrun and cold partition should pay attention to the following problems: the structure of A casting thickness should be appropriate not too thin, especially when casting size when not too thin; the B should avoid a big level, because it makes the liquid metal in the casting. Rise slowly, and the air contact surface, easy oxidation, and because the metal type liquid metal heat quickly, quickly lose liquidity, easy to cause misrun and cold lap, slag and other defects; C casting shape should be streamlined to avoid sharp corners and has sharp change connection structure in order to facilitate the flow of liquid metal. 2 in the design of metal castings in a complex shape, if the production process is very difficult, should not affect the casting conditions, try to make the casting has simple shape, strong structure change, removed from metallic die for.

- Q: How can the casting be quenched and tempered?

- Another is the result of pre heat treatment (quenching or annealing) after quenching and tempering treatment, suitable for ZG35SiMNMo, ZG35CrMo and so on. Please tell the casting process is your product and material and then set tempered.: shutup:

- Q: Why do casting parts have air holes?

- First, from the source, tools, raw material drying, in the process of melting into the reaction gas, another influence is pouring process, such as high temperature solidification gas dissolved too much after not excluded. The method can adjust the pouring temperature properly, control the source of gas (drying and controlling the inoculant, especially the content of magnesium), and add cooling iron to change the solidification mode. It depends on what kind of casting you are. You can't make it clear at once. And molding sand relationship is mainly water content and permeability, brush coating resin content.

- Q: My parts complex, machining costs are relatively high, so want to cast, but the surface needs anodizing, what material will be better?

- The common material that can be anodized is aluminum alloy. It is recommended to use casting aluminum alloys, such as ZL102 and ZL105, which are commonly used as cast aluminium alloys. The processing of aluminum casting is easy. After processing, the surface of the whole part can be anodized. The color can be chosen.

- Q: What do you mean by "proofing" in the casting? Do you charge for the proofing?

- Proofing refers to making the first sample to confirm to the customer

- Q: Lathe processing stainless steel casting parts to use what type of tool, the speed into the amount of how much tool angle

- Processing stainless steel materials, you can use YG class tools, such as YG8, YG8N. The tool geometric parameters g0=15 degrees to 18 degrees, a0=6 degrees to 8 degrees, kr=75 degrees, ls=-5 degrees to -8 degrees; cutting amount is Vc=43 m/min, ap=0.3 to 0.5 mm, f=0.16mm/r.

- Q: The difference between sheet metal and casting parts

- Casting parts are made by casting (followed by a variety of processing), the shape can be simple, can also be very complex, usually large parts, as a base, bed, work table, and so on, good seismic performance.

Send your message to us

Casting Manhole Cover Double with Customized Seal

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 110 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches