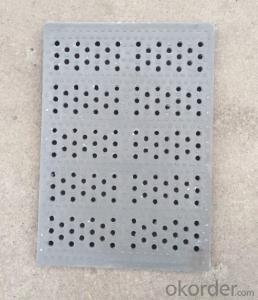

Casting Ductile Iron Manhole Covers with EN124 Standard D400 and B125

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron

3) Type: round type and Square type, triangle

4) Sand casting

5).we can produce as per customers' drawings

6)ISO9001:2008

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| TD1221 | D400 | 1220*675 | 1378*831 | 100 | 190 |

| TD1222 | D400 | 1220*675 | 1370*830 | 150 | 216 |

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1.Can I get free samples?

A: Yes, we can provide you the free sample, but you need to bear their own delivery costs.

2.Can I request to change the form of packaging and transportation?

A:Yes,We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

3.Can I request to advance the shipment?

A: It should be depends on whether there is sufficient inventory in our warehouse.

4.Can I have my own Logo on the product?

A: Yes, you can send us your drawing and we can make your logo, but you have to bear their own the cost.

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- Buffing should be better, to see how your embryo, but a bit difficult

- Q: What is normalizing, annealing, tempering, quenching? What is the difference between forging parts and casting parts?

- For the nodular cast iron, the hardness, strength and wear resistance are improved, such as used in the manufacture of automobile, tractor, diesel engine crankshaft, connecting rod and other important parts. A normalizing and hypereutectoid ball annealing before, can eliminate the mesh two cementite spheroidizing annealing, to ensure that all spheres of cementite. Annealing is a metal heat treatment process, which means the metal is slowly heated to a certain temperature, sufficient for a long time, and then cooled at an appropriate speed. The purpose is to reduce hardness, improve machinability, eliminate residual stress, stabilize size, reduce deformation and crack tendency, refine grain, adjust microstructure and eliminate tissue defects. Its purpose: (1) reduce hardness and improve machinability; (2) eliminate residual stress, stabilize size, reduce deformation and crack tendency; (3) refine grain, adjust microstructure and eliminate tissue defects. In production, annealing process is widely used.

- Q: What's the effect of casting copper?

- Riga. Copper is copper components, promote the graphitization of the copper element, make dense tissue, and to refine and improve the uniform distribution of graphite, which can reduce the chilling tendency of the cast iron, but also can promote the formation of pearlite, has a favorable effect on the section sensitivity. Copper has the tendency to strengthen cast iron, ferrite and pearlite, so it can increase the strength of cast iron. The tensile strength and bending strength of cast iron almost increase with the amount of copper in it, especially in low carbon cast iron.

- Q: Why do cheap cars like stamping parts instead of casting parts?

- The difference between automobile stamping parts and castingsAs the saying goes, there will be progress in comparison. In fact, through comparison, we can find the advantages and disadvantages of both. Next, we will talk about the difference between car stamping parts and castings.Looking for national casting orders, ductile iron castings, purchasing castings, foundry orders, and consulting foundry technology issuesCasting order networkAutomotive stamping parts are widely used in every field of our life, including some electronic components, auto parts, decorative materials and so on.

- Q: What is the difference between forging parts and casting parts?

- No, it's called die castingDifference: the die casting parts are simple in structure and large in batch sizeCasting: the use of a wide range of structures without restrictions

- Q: It is generally said that cast iron is re smelted by pig iron. My question is..:1 pig iron for melting iron, is directly cast into products (such as bed cover, etc.); or that is just the first pig iron smelting iron casting, such as to cover, bed and other products, will once again cast iron melt to casting?2, there are many castings to the engine. Are these castings made by the engine manufacturer themselves or bought by others?There is no need to answer all. Thank you!!!

- As a pig iron smelting, iron smelting belongs to physical, two belongs to the chemical refining, smelting, smelting generally not as a product after use, the product can be used as a chemical composition and casting the two refining, in general is to scrap as additional material after melting making products; engine castings have professional manufacturers making castings. You can own professional production of engine castings.

- Q: Casting parts have poor surface finish. What sand is used to make them?

- Manual coal dust, clay sand is a little worse. Mechanical styling is not bad either.

- Q: The difference between cement sand castings, resin sand castings and vacuum casting parts

- Vacuum casting is the process of using ventilation molds. Molten metal flows into the mold by air pressure, and then removes air to form a vacuum. The casting process is mainly used for small parts or jewelry with exquisite detailsCompared with the traditional clay sand casting, heat hardening resin sand casting production with low surface roughness, high precision, good quality characteristics, dimensional accuracy of resin sand mold after hardening with good rigidity and high, and not easy to deform, so in the choice of process parameters, mechanical processing you can select a smaller margin, thereby reducing the consumption of metal solution and machining cost, which can improve the dimensional accuracy of castings.

- Q: Can the casting part be phosphating with the phosphating solution of the pickling board?

- Like stainless steel casting, duplex stainless steel casting is phosphating, ductile iron gray iron is not required

- Q: Lathe processing stainless steel casting parts to use what type of tool, the speed into the amount of how much tool angle

- What kind of work, what kind of material, 204201304316, how big live ah? You ask?Can the 201 pieces of material and 304 of the pieces fit in a single car? Can I use the universal YG8 knife? Straight, knife, pipe thread?You should live to say, understand, say, do not understand, draw a simple drawing with Baidu doodle, marking the important size, this is good to answer ah!

Send your message to us

Casting Ductile Iron Manhole Covers with EN124 Standard D400 and B125

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches