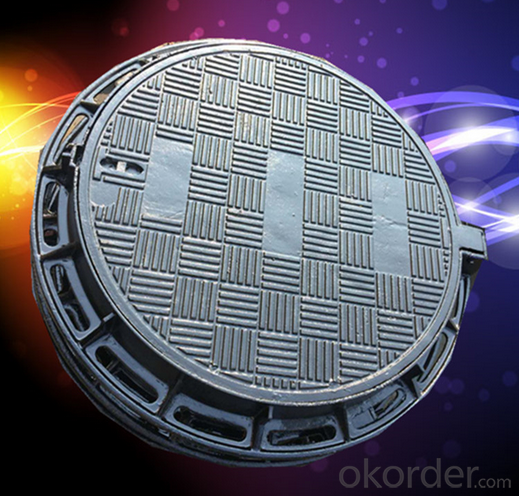

casting ductile iron manhole covers for mining and industry EN124 Standards

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron

3) Type:round type and Square type,triangle

4) Sand casting

5).we can produce as per customers'drawings

6)ISO9001:2008

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| CCUC68HK | C250 | 500*700 | 600*800 | 60 | 50 |

| CCUC70HK | C250 | 600*600 | 700*700 | 50 | 47 |

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1.Can I get free samples?

A: Yes, we can provide you the free sample, but you need to bear their own delivery costs.

2.Can I request to change the form of packaging and transportation?

A:Yes,We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

3.Can I request to advance the shipment?

A: It should be depends on whether there is sufficient inventory in our warehouse.

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- Buffing should be better, to see how your embryo, but a bit difficult

- Q: How do casting parts remove stress?

- Annealing treatment, according to different casting annealing treatment, eliminate thermal stress, if need to restore hardness or increase hardness, and then quenching treatment

- Q: Casting parts have poor surface finish. What sand is used to make them?

- V casting, EPC, precision casting of the surface is good.

- Q: What should I pay attention to when designing a casting structure?

- 1 of the casting in metal mold cooling was faster than sand, metal type and let, thus casting in metal mold casting, casting stress generated in the ratio of sand casting to crack tendency is also large, but also prone to misrun and cold lap, white (for casting casting). Defect. Usually: (1) in the prevention of metal casting casting crack aspect should pay attention to the following problems: the structure of A in wall thickness, wall transition and connection to the ease, corner fillet appropriate requirements such as should be more strict than sand casting; B should be connected vertically connected with the wall to tilt C; for the weak parts of the structure should be set to strengthen ribs, bosses, to prevent casting; D should minimize the obstacle free shrinkage of the boss, casting rib, flange and other prominent part; E in the casting arrangement of ribs, but also should consider its influence on the casting shrinkage.

- Q: How to cast iron and wrought iron collocation

- So we can only watch and ear distinction: 1, see: Iron fracture is rough, showing a bead (for the sake of coarse grain iron), and wrought iron fracture is generally more smooth; if this is a new fracture, but also to see the dark and shiny born iron wrought iron pig iron is bright; the fracture is generally irregular, because it is very brittle, mostly is interrupted, (which is processed, it is very flat and wrought iron) must not be interrupted, mostly by certain way processed separately, so the fracture is generally neat; if the fracture is that is cutting, wrought iron, iron is not cutting; iron surface will not have pores, familiar iron porosity; if a piece of iron is a significant deformation (bending) that is wrought iron because of poor plasticity It doesn't have to be so deformed, it's really bent, or it's broken, or it's obviously cracked, and it doesn't bend very much. There are some details that can not be made clear. It is necessary to have some experience.

- Q: For example, casting parts contain many holes, inclusions and other defects, the size and the number of holes exceed which limit is not qualified

- For example, the castings shall be in accordance with the requirements of the second types of castings in the technical requirements for aluminum alloy castings of GB/T9438-1999;

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: What foundry factories are used in the casting parts of China's major automobile manufacturers?

- Tangshan Yongding automobile spare parts factory also give a lot of supply, casting factory of Tangshan n to the car enterprises casting wheel gearbox etc.The team of casting experts welcome you to ask questions and accept questions!

- Q: What are the general technical requirements for casting parts?

- What kind of casting do you want to know? Copper parts, iron pieces, aluminum pieces??? Their casting conditions are different.

- Q: How to solve casting defect casting?

- Different defects, different solutions, some shortcomings, the current domestic level can not be resolved

Send your message to us

casting ductile iron manhole covers for mining and industry EN124 Standards

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches