Casting Defect Cold Welding Machine XKS-02

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 1000 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

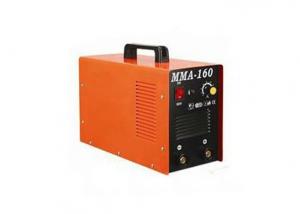

XKS-02 Casting Defect Cold Welding Machine, Spot Welder

1.Repair holes, burring,bump, scuffing, edge chipping,

2.crackle, abrasion, wear and tear

3.weld mold with no deformation

Cast iron repair/ XKS-02 Casting defect cold welding machine, Spot welder

Characteristics:

1. Not only resurfacing the metal, but also strengthen the surface coating of hard alloy such as tungsten carbide.

2. Simple operation and multi-function

3. Normal temperature welding, the structure near the welding point won't change. There is no influence in the performance of mechanic machining.

4. No any pollution in the work process, no hazardous gas, can be manually operating and look at by eyes when welding. Accurate welding position and small revision after welding.

5. The electrodes has a wide range of sources, economic and practical.

Model | XKS-02 |

Input voltage(V) | 220V Single-phase 50hz/ 60hz |

Maximum power | 2000 |

Second output voltage(V) | 20-160 |

Maximum capacity(UF) | 560 |

Frequency Variable Range(Hz)(Discharge Times/Second) | 40-2100(HZ) |

workpiece temperature in replating °C | 20-85 |

Spot Temperature (° C) | 8000-10000 |

Welding wire (Mm) | 1.0-3.2 |

Overall Dimensions (L*W*H) | 485*315*365 |

Net weight(KG) | 30 |

Application Range:

*Dies, forging dies, injection dies, die-casting, pressure casting dies, metal products, machine spare parts and other tools.

*Suitable material of all the machines

Aluminum material, aluminum alloy, copper material, copper alloy, low carbon steel, medium carbon medium, die steel, stainless steel, casting steel, cast iron, cast aluminum, tungsten carbide alloy, and all electrical conductor.

*Suitable defect of all the machines can repair

Pin holes, gas hole, burring, flash, bump, scuffing, edge chipping, pinhole porosity, crackle, abrasion, wear and tear, miscalculation in manufacture, defect in manufacture, welding defect.

*The position of all the machines can repair:

Sharp corner, sharp-edged orifice plate, groove or furrow, side wall or jamb, bottom, deep cavitiy, flat surface, and etc.

- Q: How much is 315 dual voltage welder store reallink. How much is the Taobao store?

- There are many types of action, ARC315S and ARC315 are the Vulcan series, a dual voltage (about more than 1000), is a single, there is ZX7-315GS welding dual-purpose voltage (about 1500-1800, WSME-315B is a multi) welding of Al Cu Fe three argon arc welding machine (this is expensive. Five thousand or six thousand).

- Q: 250 double voltage welding machine on two power lines, how to meet the voltage of 380?,

- If it is determined to be double voltage welding machine, two power lines: 101 fire is 220V, two are connected to the FireWire, that is, 380V.

- Q: Manual welding 250 double voltage welding machine, boot is normal, no output voltage is what is wrong

- Most of the pre - field tubes are burned, and the transformer is measured with the meter

- Q: Can pulse welding machine be changed into pulse hot welding machine?

- Pulse argon arc welding machine is an argon arc welding machine which realizes welding by pulse current. It can effectively control the heat input of welding, the penetration depth is great, and the welding seam strength is high. The better argon pulse arc welding machine is the NEBULA series digital welding machine of the nebula. The current control precision is high, the product consistency is good, and the arc concentrates.

- Q: I'd like to weld the 5mm line steel at several points on the iron plate of 3mm. What welding machine will be used?

- Just use spot welder

- Q: What are the advantages of pulse heat welding machine?

- Pulse hot welding machine adopts advanced temperature control system, which can flexibly set the heating status of each section. Temperature and time parameters can be controlled accurately; the stability of the rapid warming, local transient heating can be a good way to suppress the thermal effect on the surrounding elements; display the temperature at various stages; feedback control to improve the accuracy of temperature closed-loop thermocouple; welding pressure, welding time, welding temperature can be accurately adjusted; can store 20 set of welding parameters very convenient replacement products; more than one spot, high efficiency, good consistency, and high strength welding, solder joint appearance, simple operation; welding head life 100 thousand times, creating value for your customers.

1. Manufacturer Overview

| Location | Suzhou, Jiangsu, China (Mainland) |

| Year Established | 2006 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Mid East Western Europe |

| Company Certifications | BM TRADE;CE;SGS Certification |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Casting Defect Cold Welding Machine XKS-02

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 1000 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords