Carbon Welding Electrode /Titanium Welding

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Carbon Welding Electrode /Titanium Welding

Quick Information for Carbon Welding Electrode:

Class: ER1100

AWS: A5.10

Conforms to Certification: AWS A5.10 ASME SFA A5.10

Weld Process: Tig (GTAW)

Specifiaction of Carbon Welding Electrode:

AWS Chemical Composition Requirements | |

Cu = 0.05 – 0.20 | Al = 99.0 min |

Mn = 0.05 max | Si + Fe = 0.95 max |

Zn = 0.10 max | Be = 0.0003 max |

Other = 0.05 each – 0.15 total | |

Available Sizes:

Upon Request, call for more information

Characteristics of Carbon Welding Electrode:

Type ER1100 can be used to weld base materials types 1060, 1070, 1080, and 3003.

Welding Filler Wire

Heat Exchangers

Food Handling Equipment

Rivets

Main Features of Carbon Welding Eletrode:

The proper choice of aluminum filler metal mainly depends on the base metal properties to be achieved and welding technique. Post weld cracking, corrosion resistance and behavior under elevated temperature also need to be taken into consideration. Cracking usually can be minimized by choosing a filler metal alloy of higher alloy content then the base metal.

Deposited Chemical Composition % (Typical)

Deposited chemistry is influenced by many factors so no typical analysis can be reported.

Deposited All Weld Metal Properties %

As-Welded

Deposited all weld metal properties are influenced by many factors such as weld process used, so no typical weld metal properties can be reported.

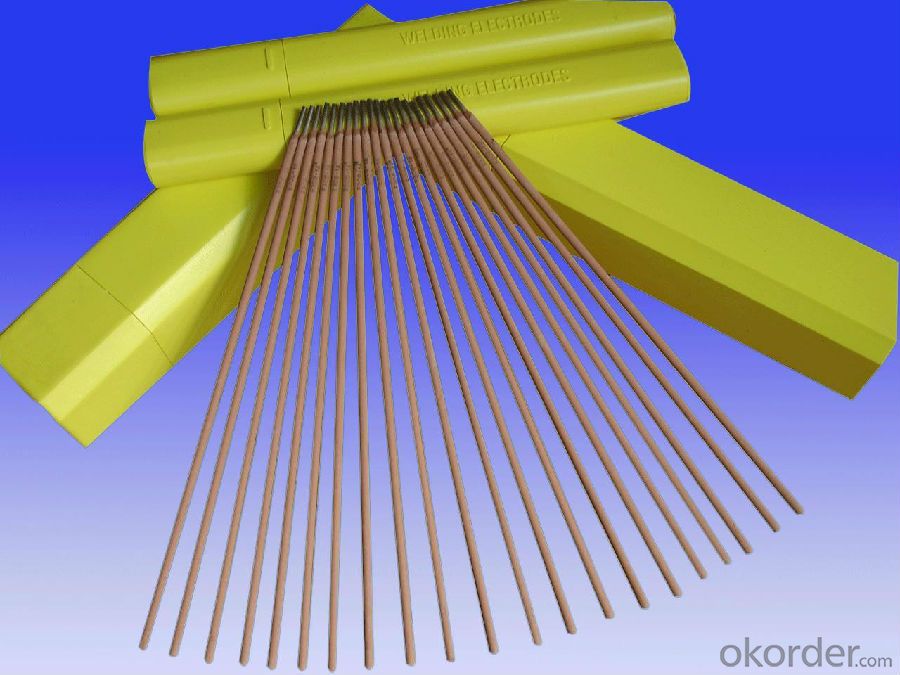

Pictures:

- Q: Is stainless steel wire suitable for heat exchangers?

- Stainless steel wire proves to be a fitting option for heat exchangers. Renowned for its outstanding corrosion resistance, robustness, and durability, stainless steel emerges as a perfect material for heat exchangers. It exhibits remarkable tolerance towards high temperatures and extreme surroundings, guaranteeing dependable and effective heat transfer. Furthermore, stainless steel wire facilitates effortless cleaning, rendering it appropriate for heat exchangers necessitating routine upkeep. All in all, stainless steel wire enjoys widespread preference in heat exchangers owing to its exceptional performance and enduring nature.

- Q: Can stainless steel wire be magnetized?

- Yes, stainless steel wire can be magnetized to a certain extent. However, compared to other materials like iron or nickel, stainless steel has a lower magnetic permeability, meaning it is less responsive to magnetism. Therefore, it requires a stronger magnetic field to be magnetized and does not retain magnetism as strongly as other ferromagnetic materials.

- Q: Can stainless steel wire be used for making wire rope?

- Yes, stainless steel wire can be used for making wire rope. Stainless steel has excellent corrosion resistance and high tensile strength, making it a popular choice for applications where durability and longevity are required. Stainless steel wire rope is commonly used in industries such as marine, construction, and aerospace, as it can withstand harsh environments and heavy loads. Additionally, stainless steel wire rope is also resistant to temperature variations, making it suitable for both high and low temperature applications.

- Q: How are stainless steel wire brushes used for cleaning grills?

- Stainless steel wire brushes are commonly used for cleaning grills due to their durability and ability to effectively remove stubborn grease and food residue. To use a stainless steel wire brush for cleaning grills, it is recommended to preheat the grill first. Once the grill is heated, the brush should be used to scrub the grates in a back and forth motion, applying moderate pressure to remove any buildup. The wire bristles are able to penetrate and dislodge the grime, while the stainless steel construction ensures the brush remains intact and rust-free. After scrubbing, it is important to thoroughly rinse off any remaining debris and clean the brush itself to maintain its effectiveness. Regular use of a stainless steel wire brush for grill cleaning helps to maintain hygiene, prevent cross-contamination, and extend the lifespan of the grill.

- Q: 201 stainless steel 667 and 669 difference

- Common stainless steel wire with good corrosion resistance and high performance price ratio is 304 and 316 stainless steel wire. Usually in accordance with Austenitic, Ferritic, two-way stainless steel and martensitic stainless steel...

- Q: Can stainless steel wire be used for HVAC ductwork?

- Yes, stainless steel wire can be used for HVAC ductwork. It is a commonly used material due to its durability, resistance to corrosion, and ability to withstand high temperatures. Additionally, stainless steel wire provides excellent structural integrity, making it suitable for HVAC ductwork installations.

- Q: Can stainless steel wire be used for hanging artwork or decorations?

- Yes, stainless steel wire can be used for hanging artwork or decorations. Stainless steel is a strong and durable material that can support the weight of various artworks or decorations, making it a suitable choice for hanging purposes.

- Q: Why do stainless steel screws still rust?

- The stainless steel screws on the shore should be made of 316 stainless steel, which can resist the corrosion of sea water.The stainless steel screws with decorative function should be cleaned and scrubbed frequently so as not to affect the appearance.Consumers should go to reputable manufacturers to choose stainless steel screws. Some of the stainless steel screws on the market do not meet the requirements of the national standards and can not meet the requirements of anti rust.

- Q: How are stainless steel wire mesh trays used in industrial drying?

- Due to their numerous advantages, stainless steel wire mesh trays find wide usage in industrial drying processes. These trays are engineered to withstand high temperatures, rendering them suitable for heat-involved drying applications. In the realm of industrial drying, stainless steel wire mesh trays are conventionally employed as holders and supporters of materials that require drying. The wire mesh construction allows for proper airflow, ensuring uniform and effective drying. The trays' open design enables the circulation of hot air through the material, facilitating quicker drying and preventing the formation of moisture pockets. Industries such as food processing, pharmaceuticals, chemicals, and textiles commonly employ these trays, as thorough and prompt drying of materials is imperative. They can be utilized in various drying methods, including convection drying, where heated air is circulated around the material, or infrared drying, where the trays are subjected to targeted drying through infrared radiation. Stainless steel wire mesh trays are favored over alternative materials like plastic or aluminum due to their durability and resistance to corrosion. They can withstand harsh chemicals, high temperatures, and heavy loads without warping or deforming, ensuring a lengthy lifespan and dependable performance. Moreover, these trays are easily cleaned and maintained, a crucial aspect in industries where hygiene is of utmost importance. The wire mesh design enables effortless removal of any debris or residue, minimizing the risk of contamination during subsequent drying cycles. In conclusion, stainless steel wire mesh trays play an indispensable role in industrial drying processes. Their ability to endure high temperatures, facilitate efficient airflow, and resist corrosion makes them highly suitable for diverse drying applications. These trays contribute to expedited drying times, enhanced product quality, and improved overall productivity in industrial settings.

- Q: Can stainless steel wire be used for safety barriers?

- Yes, stainless steel wire can be used for safety barriers. Stainless steel is known for its durability, corrosion resistance, and strength, making it an excellent choice for safety barriers that require long-term reliability and protection.

Send your message to us

Carbon Welding Electrode /Titanium Welding

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords