Carbon Steel Welding Wires Electrodes Carbon

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

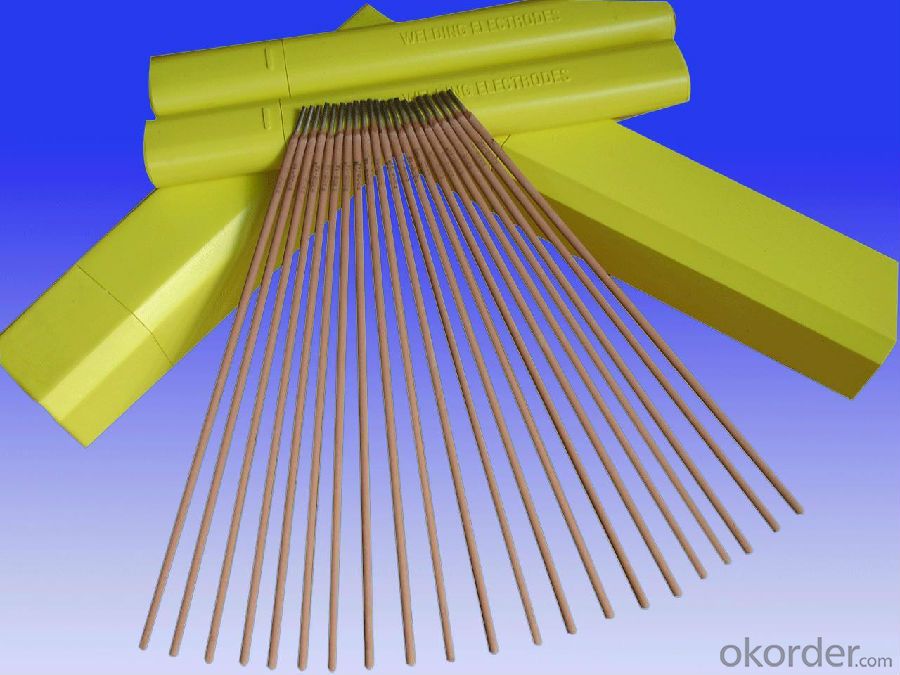

Structure of Carbon Steel Welding Wire Electrodes

1) Specially for Vertical-down welding

2) Perfect welding performance.

3)Operating current: 2.5MM:30-50,32.MM:70-100,4.0MM:90-140, 5.0MM: 150-200

4)Diameter:2.5mm-5.0mm

5)Material:Carbon Steel

6)Length:300-400mm

7)Delivery Time: 15-30 days after receiving L/C or pre-paid

Main Feature of Carbon Steel Welding Wire Electorde

Detail Package:All products will be standard export package, will be wooden boxes or bundled by steel strips, or as per customer's requirement

steel wire is a high cellulose potassium type welding rod for mild steel.

It is suitable for vertical -down welding and lap welding for sheet structures.

Such as smoke pipes, wind pipes ,oil tanks of teansformer, outside cover of vehicles.

FAQ

Why should you choose us?

Chose happens because of quality, then price, we can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents),

Quick goods delivery, our factories locate near the seaport, which is very convenient for transportation.

Datas Information of Carbon Steel Welding Wire Electorde

Chemical Composition of Deposited Metal(%)

| C | Mn | Si | S | p | Ni | Cr | Mo | V |

| ≤0.2 | ≤1.2 | ≤1.0 | ≤0.035 | ≤0.040 | ≤0.3 | ≤0.2 | ≤0.3 | less than 0.08 |

Pictures:

- Q: Can stainless steel wire be used for outdoor applications?

- Yes, stainless steel wire can be used for outdoor applications. Stainless steel is known for its excellent corrosion resistance, making it highly suitable for outdoor use where it will be exposed to moisture, humidity, and other environmental elements. It is commonly used for various outdoor applications such as fencing, wire mesh, clotheslines, outdoor sculptures, marine applications, and many others. Stainless steel wire's ability to withstand harsh weather conditions and maintain its strength and durability makes it a popular choice for outdoor projects.

- Q: What are the different types of stainless steel wire ropes used in marine applications?

- There are several different types of stainless steel wire ropes that are commonly used in marine applications. These wire ropes are specifically designed to withstand the harsh conditions and corrosive environment of the marine industry. Here are some of the most commonly used types: 1. 316 Stainless Steel Wire Rope: This is the most widely used stainless steel wire rope in marine applications. It is highly corrosion resistant and can withstand exposure to saltwater and other corrosive elements. It is also known for its high strength and durability. 2. 304 Stainless Steel Wire Rope: This type of stainless steel wire rope is also commonly used in marine applications. It offers good corrosion resistance, although not as high as 316 stainless steel. It is also known for its high tensile strength and resistance to abrasion. 3. 316L Stainless Steel Wire Rope: This is a low carbon version of 316 stainless steel wire rope. It offers similar corrosion resistance and strength properties as 316 stainless steel, but with lower carbon content, it is more resistant to sensitization and intergranular corrosion. 4. 7x19 Stainless Steel Wire Rope: This type of wire rope consists of 7 strands, each containing 19 individual wires. It offers excellent flexibility and is commonly used in applications where high flexibility and corrosion resistance are required, such as marine rigging, lifelines, and fishing nets. 5. 1x19 Stainless Steel Wire Rope: This wire rope consists of a single strand with 19 individual wires. It is known for its high tensile strength and is commonly used in standing rigging applications on sailboats, such as shrouds and stays. 6. 7x7 Stainless Steel Wire Rope: This wire rope consists of 7 strands, each containing 7 individual wires. It offers good flexibility and is commonly used in applications where moderate flexibility and corrosion resistance are required, such as guardrails and balustrades. 7. 6x19 Stainless Steel Wire Rope: This wire rope consists of 6 strands, each containing 19 individual wires. It offers a good balance between flexibility and strength and is commonly used in marine applications, such as winches, cranes, and hoists. These are just a few examples of the different types of stainless steel wire ropes used in marine applications. The specific type of wire rope used will depend on the requirements of the application, such as the desired level of corrosion resistance, strength, flexibility, and durability.

- Q: Elevator hairline stainless steel and wire drawing stainless steel what is the difference between the two costs which expensive ah?

- Lift the hairline stainless steel as mentioned above, is a short wire drawing process, the price a little expensive, of course, the price of the elevator itself and less material. The price mainly depends on the level of the elevator: 1, brand and technology, 2, traction machine control cabinet door machine system etc. the advantages and disadvantages of the 3, is the (decoration material is only a small part of the decoration)

- Q: 201 stainless steel 667 and 669 difference

- Stainless steel wire and stainless steel wire, various specifications and models of silk production as raw materials of stainless steel, the origin of the United States, Holland, Japan, the general section is round or flat.

- Q: What are the different types of stainless steel wire ropes for rigging?

- There are several types of stainless steel wire ropes commonly used for rigging purposes, including 1x19, 7x7, and 7x19 constructions. 1x19 wire rope is made up of a single strand with 19 wires, offering high tensile strength and minimal flexibility, making it suitable for straight line applications. 7x7 wire rope consists of 7 strands, each with 7 wires, providing moderate flexibility and strength, making it suitable for general purpose rigging. Lastly, 7x19 wire rope is made up of 7 strands, each with 19 wires, offering excellent flexibility and strength, making it ideal for applications requiring a combination of both.

- Q: Is stainless steel wire suitable for wire rope swivels?

- Yes, stainless steel wire is suitable for wire rope swivels. Stainless steel is known for its high strength, durability, and corrosion resistance, making it an ideal material for applications that require reliable and long-lasting performance, such as wire rope swivels. Stainless steel wire provides excellent flexibility and resistance to rust, making it a suitable choice for various industrial and marine applications.

- Q: Is stainless steel wire suitable for filtration applications?

- Yes, stainless steel wire is suitable for filtration applications. Stainless steel wire has excellent corrosion resistance and high strength, making it ideal for filtering out particles and contaminants in various industries such as oil and gas, food and beverage, and pharmaceuticals. Its durability and ability to withstand high temperatures and pressure make it a reliable choice for filtration systems.

- Q: Is stainless steel wire suitable for architectural mesh applications?

- Yes, stainless steel wire is highly suitable for architectural mesh applications. It offers durability, strength, and corrosion resistance, making it ideal for both indoor and outdoor use. Additionally, stainless steel wire can be woven into various intricate patterns, providing aesthetic appeal and allowing for creative designs in architectural projects.

- Q: Can stainless steel wire be used for wire rope fences?

- Wire rope fences can indeed utilize stainless steel wire. The strength, durability, and corrosion resistance of stainless steel wire make it an ideal choice for outdoor applications like fences. When enhanced security and strength are necessary, wire rope fences are commonly employed in industrial sites, farms, and high-security facilities. Not only do stainless steel wire rope fences provide security and strength, but they also boast a sleek and contemporary design that adds aesthetic appeal. Furthermore, these fences require minimal maintenance due to their resistance to rust and ability to withstand harsh weather conditions. All in all, stainless steel wire rope is a dependable and enduring material for constructing fences, guaranteeing the safety and protection of the surrounding area.

- Q: What's the effect of soapy water used to soak stainless steel wire?

- If you look carefully, the bubbles will be colorful in the sun. This is because the sun is actually a colorless: seemingly complex light consists of red, orange, yellow, green, green, blue, purple and other seven kinds of monochromatic light, if somewhere in the soap film that two shares of the reflected light offset, in this place can not see the red and blue green. The same way, in the other part, a light has been strengthened, showing is another color. Soap bubbles are made of a thin layer of transparent cellophane, and when the sun shines on the soap film, it reflects both inside and outside.

Send your message to us

Carbon Steel Welding Wires Electrodes Carbon

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords