Carbon Steel Round Bar with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Carbon Steel Round Bar with High Quality

Specification

1, Diameter: 8mm-250mm rounds

5mm-9mm rods

2, Length: 2m, 3m, 5.8m, 6m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black, Polished, Galvanized

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

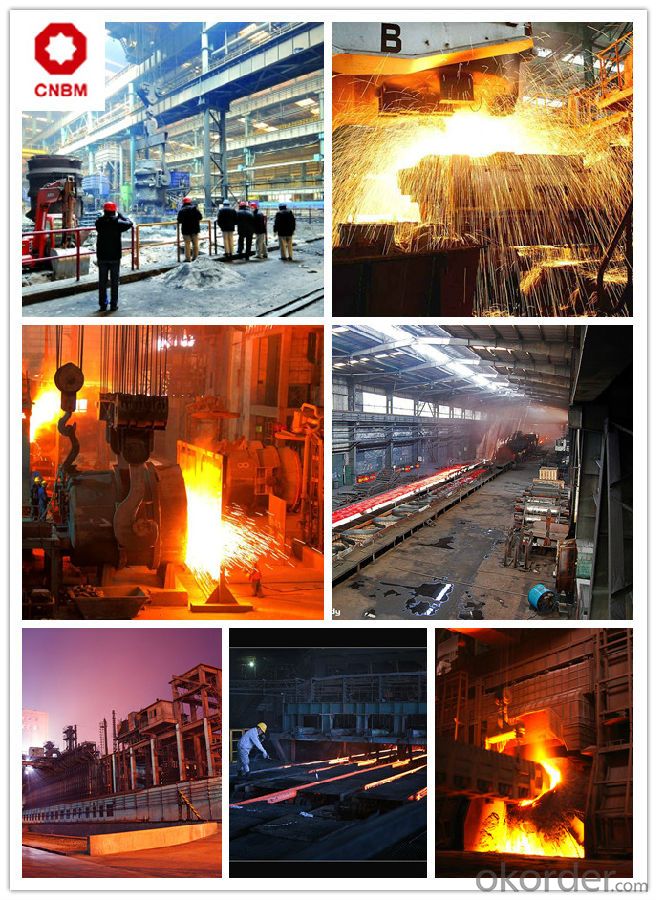

Products Show

Product Overviews

Description |

Carbon Steel Rod/Carbon Steel Bar,carbon steel rod,carbon steel shaft,mild steel bar, mild steel shaft,ms bar | |

Material |

ASTM |

1005,1006,1008,1010,1015,1020,1025,1030,1035,1040,1045,1050,1055,1060, 1065,1070,1080,1084,1016,1022 |

DIN |

Ck10,Ck15,Ck22,Ck25,Ck30,Ck35,Ck40,Ck45,Ck50, 30Mn4,40Mn4 | |

BS |

040A04,095M15,045M10,080A40,045M10,080M50 | |

Standard | GB/T799,ASTM A29,A108,A321,A575,BS970,DIN1652,JIS G4051 | |

Section shape |

Round | |

Length |

As your required | |

Application | Carbon steel rod applies to chemical industry, shipping industry,manufacturing industry,construction, decorate Industry,electric power,pump shafts, sanitary wares,furniture handles,boiler,high temperature resistant,low temperature resistant, corrosion resistant. | |

Work Shop

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: What are the different types of steel round bar sizes?

- Steel round bars come in a variety of sizes, each serving different purposes and applications. The most common sizes for steel round bars range from 1/8 inch to 24 inches in diameter. These sizes are typically measured in inches, with each increment representing a larger diameter. For smaller projects or more intricate designs, steel round bars ranging from 1/8 inch to 1 inch are often used. These smaller sizes are commonly found in jewelry making, crafting, and smaller construction projects. On the other hand, steel round bars ranging from 1 inch to 24 inches are utilized for larger-scale applications such as structural support, manufacturing, or industrial projects. These larger sizes provide enhanced strength and durability, making them suitable for heavy-duty use. It should be noted that steel round bars are also available in metric sizes, which are measured in millimeters. Metric sizes are commonly used in regions that follow the metric system, such as many countries in Europe and Asia. Choosing the appropriate size of steel round bar depends on the specific requirements of the project, including load-bearing capacity, structural integrity, and overall design. It is advisable to seek advice from an engineer or industry professional to determine the most suitable size for your particular application.

- Q: How are steel round bars heat treated?

- Steel round bars are typically heat treated through a process called quenching and tempering. First, the bars are heated to a specific temperature to transform the internal structure of the steel. Then, they are rapidly cooled by quenching in a liquid, such as oil or water, to harden the steel. Finally, tempering is performed by reheating the bars to a lower temperature to reduce brittleness and enhance toughness. This heat treatment process improves the strength, hardness, and overall performance of steel round bars.

- Q: Can steel round bars be used in the production of medical equipment?

- Medical equipment can indeed utilize steel round bars. This is because steel is a widely employed material in the production of medical devices and equipment. Its strength, durability, and versatility make it a popular choice. By utilizing steel round bars, one can fashion various components of medical equipment, including surgical instruments, orthopedic implants, diagnostic tools, and hospital furniture. Steel possesses desirable properties, such as resistance to corrosion and the ability to be sterilized, rendering it suitable for use in the medical sector where hygiene and patient safety are paramount. Furthermore, steel round bars can be easily machined and fabricated into different shapes and sizes, allowing for the customization of medical equipment to fulfill specific requirements.

- Q: Can steel round bars be used for making jewelry?

- While gold and silver are commonly used for jewelry making, steel round bars can also be utilized in this craft. Steel round bars are particularly favored in industrial or modern jewelry designs due to their sleek and contemporary appearance. Moreover, steel possesses remarkable durability, resistance to tarnish, and affordability compared to other metals, making it an attractive option for those seeking a more economical choice. Nonetheless, it is worth noting that steel may not be suitable for delicate or intricate jewelry designs as it tends to be heavier than alternative metals. Furthermore, individuals with metal allergies should exercise caution as steel can potentially cause skin reactions. In such cases, it is advisable to opt for hypoallergenic or coated steel to ensure safety. Ultimately, the decision to incorporate steel round bars into jewelry making is contingent upon the desired style, durability, and budget preferences of the creator or purchaser.

- Q: How do you calculate the bending stress in a steel round bar?

- In order to determine the bending stress in a steel round bar, one must take into account the applied load and the properties of the bar. The bending stress is a measurement of the internal forces that arise within the bar when it is subjected to an external load that causes it to bend. The bending stress can be calculated using the following formula: σ = (M * c) / I In this equation: - σ denotes the bending stress, measured in units of force per unit area (such as pascals or psi) - M represents the bending moment, which is the result of multiplying the applied load by the distance from the bar's neutral axis to the point of interest. It is typically expressed in units of force multiplied by distance (e.g., N·m or lb·ft). - c signifies the distance from the neutral axis to the outermost fiber of the bar. It is also referred to as the distance to the extreme fiber or the radius of the bar. - I symbolizes the moment of inertia, which portrays the bar's resistance to bending. It is a property that relies on the shape and dimensions of the bar's cross-section. To calculate the moment of inertia for a round bar, the formula is as follows: I = (π * d^4) / 64 In this equation: - I denotes the moment of inertia - π represents a mathematical constant (approximately 3.14159) - d signifies the diameter of the round bar Once the bending stress has been determined using the aforementioned formulas, it can be compared to the yield strength of the steel material to evaluate the safety factor and ascertain whether the bar will experience permanent deformation or failure.

- Q: Can steel round bars be used for making suspension components?

- Yes, steel round bars can be used for making suspension components. Steel is a common material used in the manufacturing of suspension components due to its high strength and durability. Steel round bars can be machined or forged into various shapes and sizes to meet the specific requirements of suspension components such as control arms, sway bars, and tie rods. The use of steel round bars ensures the suspension components can withstand the forces and stresses encountered during vehicle operation, providing stability, control, and safety.

- Q: Are steel round bars available in different colors?

- No, steel round bars are typically available in a silver or gray color as they are made from alloyed iron and carbon.

- Q: Can steel round bars be coated with protective coatings?

- Indeed, it is possible to apply protective coatings to steel round bars. These coatings function as a shield, safeguarding the steel against corrosion, abrasion, and other forms of harm. The most prevalent form of protective coating for steel round bars is known as a corrosion-resistant coating. It is typically administered using methods such as hot-dip galvanization, electroplating, or powder coating. These coatings establish a protective layer that prevents the steel from encountering corrosive substances, moisture, and other environmental elements that may lead to deterioration. Furthermore, these coatings have the potential to enhance the aesthetic appeal of the steel round bars and extend their lifespan.

- Q: How do steel round bars resist corrosion?

- Steel round bars possess corrosion resistance due to a variety of factors. To begin with, steel itself is an alloy primarily composed of iron and carbon. By incorporating other elements like chromium, nickel, and molybdenum, the corrosion resistance of steel is enhanced. These additional elements create a protective oxide layer on the steel's surface, acting as a barrier against corrosive substances in the surroundings. Moreover, steel round bars can undergo further surface treatments or coatings to augment their corrosion resistance. One commonly used technique is galvanization, which involves coating the steel with a layer of zinc. This zinc coating serves as a sacrificial layer, deteriorating before the steel itself is affected. Additionally, steel round bars can be coated with epoxy or other polymer coatings to provide an additional layer of safeguarding. It is also crucial to recognize that the manufacturing process and quality of the steel round bars significantly influence their corrosion resistance. Proper heat treatment, refining techniques, and quality control measures guarantee a homogeneous microstructure and minimal impurities in the steel, thereby reducing the probability of corrosion. In conclusion, the combination of alloying elements, surface treatments, and high-quality manufacturing processes contribute to the corrosion resistance of steel round bars, rendering them a dependable choice for applications in corrosive environments.

- Q: Can steel round bars be used for making bridges?

- Yes, steel round bars can be used for making bridges. Steel is a commonly used material in bridge construction due to its high strength and durability. Round bars, also known as reinforcing bars or rebars, are often used to reinforce concrete structures, including bridge decks and piers. They provide additional tensile strength and help to distribute loads more evenly, making the bridge more resistant to bending or twisting forces. Additionally, round bars can be used as structural elements in the construction of cable-stayed or suspension bridges, where they are used to support and strengthen the main load-bearing cables. Overall, steel round bars are a versatile and reliable choice for bridge construction, offering the necessary strength and stability required to withstand the heavy loads and harsh environmental conditions experienced by bridges.

Send your message to us

Carbon Steel Round Bar with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords