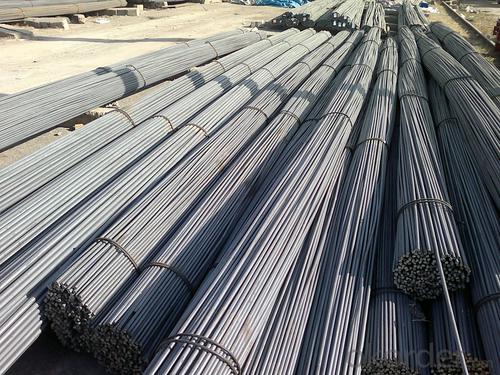

Carbon steel round bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Steel Grade: | Standard: | Dimensions: | |||

| Place of Origin: | Brand Name: | Model Number: | |||

| Technique: | Application: | Alloy Or Not: | |||

| Special Use: | Type: | LENGTH: | |||

| COMMODITY: | SPEC: | SIZE: |

Packaging & Delivery

| Packaging Detail: | Packing Term: Bulk Packing Or Container. |

| Delivery Detail: | Within 30-45 days as of the date of contract signing |

Specifications

ROUND BAR (S45C,S20C,SS400,A36)

1.Length:6m to 12m

2.Grade:Q235/SS400/S20C/S45C

Remarks:

1.Origin / Manufacturer: China

2.Port of Loading: Tianjin Port,China

3.Packing Term: Bulk Packing Or Container

4.Measurement of Weight: By Theoretical Weighting

5.Certificate:ISO9001,CIC,BV,SGS

- Q: What is the difference between a centerless ground and a rough turned steel round bar?

- The manufacturing processes and resulting surface finishes of a centerless ground steel round bar and a rough turned steel round bar differ. To produce a centerless ground steel round bar, the bar is fed through a grinding machine. This machine removes material from the surface, achieving precise diameter and roundness tolerances. The bar is rotated between two grinding wheels, while pressure is applied to remove imperfections and create a smooth, polished surface. The end result is a highly accurate and consistent diameter, with a mirror-like finish. This makes it suitable for applications that require tight tolerances and a polished appearance. On the other hand, a rough turned steel round bar is manufactured using a different machining process called turning. In this process, the bar is rotated against a cutting tool, which removes material from the surface to achieve the desired diameter and shape. However, turning does not provide the same level of precision and surface finish as centerless grinding. The resulting surface of a rough turned bar will have visible tool marks and a rougher texture compared to a centerless ground bar. In conclusion, the main distinction between a centerless ground steel round bar and a rough turned steel round bar lies in their manufacturing processes and resulting surface finishes. Centerless grinding offers a more precise diameter, roundness, and smoother surface finish, making it ideal for applications that require tight tolerances and a polished appearance. Rough turning, while less precise and with a rougher surface finish, is still suitable for applications that do not require the same level of precision or aesthetic appeal.

- Q: What are the different types of steel round bars used in the power generation industry?

- In the power generation industry, various types of steel round bars are utilized for different applications. These round bars are specifically chosen for their unique properties and characteristics that are required in various power generation processes. Some of the different types of steel round bars commonly used in the power generation industry include: 1. Carbon Steel Round Bars: Carbon steel round bars are widely used due to their affordability, strength, and ease of fabrication. They are commonly used in power generation equipment such as turbines, generators, and boilers. 2. Alloy Steel Round Bars: Alloy steel round bars are made by combining carbon steel with other elements such as chromium, nickel, and molybdenum to enhance their mechanical properties. These bars offer increased strength, corrosion resistance, and heat resistance, making them suitable for high-pressure and high-temperature applications in power plants. 3. Stainless Steel Round Bars: Stainless steel round bars are highly corrosion-resistant and exhibit excellent heat resistance. They are commonly used in power generation equipment that comes into contact with water or steam, such as condensers, heat exchangers, and valves. 4. Tool Steel Round Bars: Tool steel round bars are known for their exceptional hardness, wear resistance, and toughness. They are commonly used in power generation equipment that undergoes frequent machining, cutting, or forming processes, such as drilling equipment and turbine blades. 5. High-Speed Steel Round Bars: High-speed steel round bars are specifically designed to withstand high temperatures and maintain their hardness and cutting ability at elevated speeds. They are commonly used in power generation equipment, such as cutting tools, drills, and milling machines. 6. Duplex Steel Round Bars: Duplex steel round bars are a combination of austenitic and ferritic stainless steels, offering excellent strength, corrosion resistance, and weldability. They are commonly used in power plants for applications such as piping systems, pressure vessels, and heat exchangers. It is worth noting that the specific steel round bars used in the power generation industry can vary depending on the requirements and operating conditions of each power plant. Therefore, it is essential to consult with engineers and experts to determine the most suitable type of steel round bars for a particular power generation application.

- Q: Can steel round bars be bent or formed?

- Yes, steel round bars can be bent or formed. They have the ability to be shaped into various angles or curves through the application of force, typically using tools such as a hydraulic press or bending machine.

- Q: What is the elongation of a steel round bar?

- The elongation of a steel round bar refers to the amount of lengthening or stretching the bar undergoes when subjected to an applied force or load.

- Q: What are the different joining methods for steel round bars?

- There are several different joining methods that can be used for steel round bars, depending on the specific application and desired outcome. Some of the most common joining methods for steel round bars include welding, brazing, and mechanical joining. 1. Welding: Welding is a popular method for joining steel round bars. It involves melting the edges of the bars and fusing them together using heat. Various welding techniques such as arc welding, MIG welding, TIG welding, and spot welding can be used, depending on the thickness and type of steel being joined. Welding provides a strong and permanent bond, making it suitable for heavy-duty applications. 2. Brazing: Brazing is another method used to join steel round bars. It involves heating the bars and melting a filler metal that has a lower melting point than the steel. The molten filler metal is then drawn into the joint by capillary action, creating a strong bond when it solidifies. Brazing is often used when the base metals have different melting points or when a lower-temperature joining process is required. 3. Mechanical joining: Mechanical joining methods do not involve any heat or melting of the steel round bars. Instead, they rely on mechanical means to hold the bars together. Examples of mechanical joining methods include bolted connections, riveting, and clamping. These methods are often used when disassembly or adjustability is required, as they provide a non-permanent joint that can be easily undone. It is important to consider factors such as the strength requirements, environmental conditions, and the specific application when choosing a joining method for steel round bars. Each method has its own advantages and limitations, and the appropriate joining method should be selected to ensure a secure and durable bond between the round bars.

- Q: Are steel round bars used in the construction industry?

- Steel round bars are widely utilized in the construction industry due to their versatility. They find applications in reinforcing concrete structures, providing structural support in buildings, and fabricating components for bridges, highways, and other infrastructure projects. These bars possess remarkable strength and durability, enabling them to endure heavy loads and harsh environmental conditions. Moreover, their uniform shape and smooth surface facilitate easy welding, bending, and machining, rendering them an excellent option for construction endeavors.

- Q: Can steel round bars be used for making propeller shafts?

- It is indeed possible to utilize steel round bars in the production of propeller shafts. The utilization of steel in propeller shafts is widespread due to its robustness, endurance, and ability to withstand corrosion. In particular, round bars are frequently favored due to their shape, which offers exceptional strength and load-bearing capabilities. The decision regarding the steel grade and specific properties will be contingent upon the propeller shaft's requirements, such as the desired dimensions in terms of length, diameter, and torque capacity. Moreover, factors like cost, weight, and manufacturability may also play a role in influencing the selection of steel round bars for propeller shafts.

- Q: How do steel round bars compare to glass round bars?

- Steel round bars are significantly stronger and more durable compared to glass round bars. Steel is a metallic material that offers high tensile strength and can withstand heavy loads, making it suitable for structural applications. On the other hand, glass round bars are more fragile and prone to breakage under stress. However, glass round bars have a more aesthetic appeal and are commonly used in decorative applications. The choice between steel and glass round bars depends on the specific requirements of the project, with steel being preferred for strength and glass for its visual qualities.

- Q: How do steel round bars perform under impact or shock loading?

- Steel round bars are known for their exceptional performance under impact or shock loading. Due to their high strength and toughness, steel round bars can withstand sudden forces and resist deformation or failure. The inherent properties of steel, such as its hardness and ductility, contribute to its ability to absorb energy and distribute it throughout the material, minimizing the impact on the structure. When subjected to impact or shock loading, steel round bars undergo plastic deformation, which allows them to absorb the applied energy without breaking. The ability to absorb energy is crucial in various applications, such as construction, automotive, and machinery industries, where components are often subjected to dynamic loads. Additionally, steel's excellent fatigue resistance further enhances its performance under impact or shock loading. Even when subjected to repeated impacts, steel round bars can withstand the cyclic loading without undergoing significant degradation in their mechanical properties. Moreover, steel round bars can be further enhanced through various heat treatment processes, such as quenching and tempering, to improve their resistance to impact or shock loading. These processes help to refine the microstructure of the steel, resulting in increased strength, toughness, and hardness. In conclusion, steel round bars have a remarkable performance under impact or shock loading. Their high strength, toughness, and ability to absorb energy make them reliable and widely used in applications where sudden forces or dynamic loads are expected.

- Q: Can steel round bars be used in the transportation industry?

- Steel round bars are indeed applicable to the transportation industry due to their strength and durability. They possess qualities that make them well-suited for transportation applications, where safety, reliability, and load-bearing capacity are crucial. In this sector, steel round bars serve various purposes, including the construction of vehicle frameworks, the production of axles, drive shafts, suspension components, and other critical parts. The exceptional tensile strength of steel ensures that these components can endure heavy loads and vibrations, making them appropriate for use in trucks, buses, cars, trains, and other modes of transportation. Furthermore, steel round bars can be easily machined and fabricated into different shapes, enabling customization and adaptation to specific transportation requirements.

Send your message to us

Carbon steel round bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords