Carbon Steel Hot Rolled Wire Rod with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Carbon Steel Wire Rod at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Carbon Steel Wire Rod are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.After hot-rolled the products shaped into coil and delivery as finished product, including round, square, rectangular, hexagonal and so on. Since most of the products are round, it is generally called wire rod. Carbon steel wire rod is widely used in construction and manufacturing. Carbon steel wire rod is mainly used for reinforcement of reinforced concrete and welded structure or reprocessed (roberts , nail, etc.) materials, especially used to produce wire drawing, welding electrode, nails, spring, electronic, precise machinery parts and so on.

Product Advantages:

OKorder's Carbon Steel Wire Rod are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Chemical Composition:

Please kindly find our chemistry of our material based on SAE1008B as below for your information

Trademark | Rank | Chemical composition (quality score) % | |||||

C | Si | Mn | S | P | |||

≤ | ≤ | ≤ | |||||

Q235 | A | 0.14-0.22 | 0.30 | 0.30-0.65 | 0.050 | 0.045 | |

Q235 | B | 0.12-0.20 | 0.30 | 0.30-0.70 | 0.045 | 0.045 | |

Trademark | Rank | Pulling Test | |||||

Bend PointΔs/Mpa | Tensile Strength | Elongation Ratioδ5% | |||||

Thickness (Diameter) /MM | Thickness (Diameter) /MM | ||||||

≤16 | 16-40 | ≤16 | 16-40 | ||||

≥ | ≥ | ||||||

Q235 | A | 235 | 225 | 375-500 | 26 | 25 | |

Q235 | B | 235 | 225 | 375-500 | 26 | 25 | |

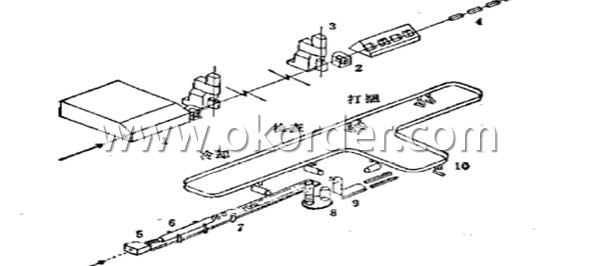

Production Process of Wire Rod

1-Furnace 2-Roughing Mill 3-High-speed Finishing Mill 4-Water-cooled Device 5-Coiling Device

6-Cooling Device 7-Chain Conveyer 8-Spool Collecting Device 9-Spool Down Device 10-Hook Conveyer

Packaging & Delivery of Wire Rod:

Packaging Detail: products are packed in coil and then shipped by container or bulk vessel

Each coil weight: 2-3MT

Delivery Detail: within 45 days after received deposit or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: CFR, CIF

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Image

- Q: What are the main factors influencing the choice of steel wire rod order confirmation process?

- The main factors influencing the choice of steel wire rod order confirmation process include the quantity and quality of the order, customer preferences and requirements, availability of inventory, production capacity, lead time, pricing, payment terms, and contractual agreements.

- Q: What are the common industry qualifications for steel wire rod suppliers?

- The common industry qualifications for steel wire rod suppliers typically include certifications such as ISO 9001:2015 for quality management systems, ISO 14001:2015 for environmental management systems, and OHSAS 18001:2007 for occupational health and safety management systems. Additionally, suppliers may be required to adhere to industry-specific standards such as ASTM A510, ASTM A370, and ASTM A510M. It is also important for suppliers to have a strong track record of delivering consistent quality products, meeting customer specifications, and maintaining reliable production and delivery capabilities.

- Q: What are the standard tolerances for steel wire rod?

- The standard tolerances for steel wire rod can vary depending on the specific grade and application. However, common tolerances range from +/- 0.002 inches to +/- 0.010 inches for diameter, and +/- 0.010 inches to +/- 0.030 inches for straightness. These tolerances ensure the required level of accuracy and consistency in the manufacturing and use of steel wire rods.

- Q: What are the different types of coatings for steel wire rod?

- There are several different types of coatings that can be applied to steel wire rods to enhance their performance and protect them from corrosion. Some of the commonly used coatings include: 1. Zinc Coating: Zinc coating, also known as galvanization, is one of the most popular coatings for steel wire rods. It provides excellent corrosion resistance and can be applied through hot-dip galvanizing or electroplating methods. 2. Polymer Coating: Polymer coatings are often used to provide additional protection against corrosion and abrasion. These coatings can be applied by dip coating, extrusion, or powder coating methods, and they offer good adhesion and flexibility. 3. Phosphate Coating: Phosphate coatings are commonly used as a pre-treatment on steel wire rods before applying other coatings. They enhance the adhesion of subsequent coatings and improve corrosion resistance. 4. Epoxy Coating: Epoxy coatings are known for their excellent adhesion and chemical resistance. They are often used in industrial settings where the wire rods are exposed to harsh environments or corrosive substances. 5. Powder Coating: Powder coatings offer a durable and decorative finish to steel wire rods. These coatings are applied as a dry powder and then cured under heat to create a smooth, protective layer. 6. Organic Coating: Organic coatings, such as acrylics or polyurethanes, are often used for aesthetic purposes or to provide a specific color to the wire rods. These coatings also offer some degree of protection against corrosion. 7. Ceramic Coating: Ceramic coatings are used in high-temperature applications where the wire rods are exposed to extreme heat or thermal cycling. These coatings provide excellent heat resistance and can withstand thermal shocks. It's important to choose the appropriate coating based on the specific requirements and intended use of the steel wire rods. Different coatings offer varying levels of protection, durability, and resistance to specific environmental factors.

- Q: What are the common industry best practices for steel wire rod distributors?

- Some common industry best practices for steel wire rod distributors include maintaining a robust supply chain management system, ensuring quality control and product traceability, providing timely and accurate order fulfillment, offering competitive pricing, establishing strong relationships with suppliers and customers, investing in modern technology and equipment for efficient operations, and prioritizing customer satisfaction through excellent communication and after-sales support.

- Q: How is steel wire rod used in the manufacturing of wire for mattress springs?

- The manufacturing of wire for mattress springs relies heavily on steel wire rod. This component serves as the primary raw material and undergoes various processes to become the final wire used in mattress spring production. To initiate the manufacturing process, careful selection of steel wire rod is essential. Its specific properties, including tensile strength, flexibility, and durability, are crucial factors in ensuring that the wire can withstand the pressure and weight exerted on it when incorporated into mattress springs. Once the suitable steel wire rod is chosen, it goes through a series of manufacturing steps. Initially, the wire rod is heated to extremely high temperatures, making it more malleable and easier to manipulate. This process, known as annealing, also eliminates any internal stresses within the wire rod, enhancing its resistance to fatigue and extending its lifespan. After annealing, the steel wire rod undergoes cold-drawing, a process that involves reducing its diameter and increasing its strength and flexibility by pulling it through a sequence of progressively smaller holes. Once the wire rod reaches the desired diameter, it undergoes further processing to improve its surface finish and eliminate any imperfections. This can be achieved through methods such as cleaning, polishing, or applying a protective coating to the wire. Lastly, the wire is coiled into springs. This is accomplished by feeding the wire into a specialized machine that coils it around a mandrel, resulting in the individual springs used in mattresses. The diameter and number of turns in the coil can be adjusted to meet the specific requirements of different mattress types. In conclusion, steel wire rod is an essential component in the manufacturing of wire for mattress springs. Through processes like annealing and wire drawing, it is transformed to enhance its strength, flexibility, and durability. Ultimately, the coiled wire springs provide the necessary support and comfort for mattresses.

- Q: What are the common testing methods for steel wire rod?

- Common testing methods for steel wire rod include tensile testing, hardness testing, bend testing, impact testing, and surface inspection.

- Q: How is steel wire rod used in the production of wire for jewelry making?

- Wire rod made from high-quality steel is essential in the manufacturing process of jewelry wire. This type of steel is renowned for its durability and strength. To achieve the desired dimensions, the steel wire rod is drawn through a series of dies, resulting in an increase in length and a reduction in diameter. This process, known as wire drawing, is crucial in jewelry making. Once the wire reaches the desired dimensions, it undergoes further processing to meet the specific requirements of jewelry production. Depending on the design and style of the jewelry piece, the wire can be shaped into various forms, including round, square, or flat wire. Steel wire rod is widely used in jewelry making due to its versatility and affordability. It provides the necessary strength and support for delicate jewelry pieces, such as necklaces, bracelets, and earrings. The wire can be easily manipulated to create intricate designs, loops, and bends without compromising its shape or strength. Apart from its structural properties, steel wire rod is often coated with a protective layer of metal plating, such as silver or gold. This plating not only enhances the appearance of the wire but also prevents tarnishing. The process of plating adds a decorative finish to the wire, enabling jewelry makers to create visually striking and captivating pieces. All in all, the significance of steel wire rod in the production of jewelry wire cannot be overstated. Its strength, flexibility, and affordability make it an ideal material for crafting durable and exquisite jewelry pieces. Whether used as the primary component or as a supportive element in intricate designs, steel wire rod is an indispensable resource in the art of jewelry making.

- Q: How are steel wire rods used in the production of welding electrodes?

- Steel wire rods are essential components in the production of welding electrodes. These wire rods serve as the core material for welding electrodes, providing the necessary strength and conductivity required for the welding process. To begin the production of welding electrodes, steel wire rods are first selected based on their specific mechanical properties, such as tensile strength and elongation. These properties ensure that the welding electrodes will be able to withstand the high temperatures and stress experienced during the welding process. The steel wire rods are then further processed through a series of steps. They are first cleaned and coated with a flux material, which helps to remove impurities and promote better arc stability during welding. This coating also assists in the formation of a protective gas shield around the welding area, preventing oxidation and contamination. After the coating process, the steel wire rods are cut into specific lengths and shaped into the desired electrode design. This can involve bending or forming the rods to achieve the required shape and size of the welding electrode. Once the welding electrode is formed, it is then packaged and made ready for distribution and use. These electrodes are widely used in various industries, including construction, automotive, and manufacturing, for welding applications such as joining metals, repairing machinery, and fabricating structures. In summary, steel wire rods play a crucial role in the production of welding electrodes. They provide the necessary strength, conductivity, and formability required for these electrodes to effectively carry out welding processes.

- Q: What are the different packaging materials used for steel wire rod?

- Packaging materials for steel wire rods vary based on factors such as length, weight, protection needed during transportation, and ease of handling. Commonly used materials include steel coils, wooden reels, pallets, cardboard boxes, and plastic wraps. Steel coils are a popular option, as they provide compact and secure packaging that is easy to transport and handle. For longer and heavier wire rods, wooden reels offer a larger and more stable packaging solution, commonly used in construction and industrial applications. Pallets are another option, providing a stable base for wire rods and enabling easy handling with forklifts or pallet jacks. Cardboard boxes are suitable for smaller or specific length wire rods, offering protection during transportation and facilitating storage. In some cases, plastic wraps are used for steel wire rods, particularly when smaller quantities need protection from moisture or dust during transportation. It should be noted that the choice of packaging material depends on the specific requirements of the manufacturer and end user, as well as factors like cost, transportation method, and storage conditions.

Send your message to us

Carbon Steel Hot Rolled Wire Rod with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords