Hot Rolled High Quality Carbon Steel Wire Rod

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Carbon Steel Wire Rod at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Carbon Steel Wire Rod are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.After hot-rolled the products shaped into coil and delivery as finished product, including round, square, rectangular, hexagonal and so on. Since most of the products are round, it is generally called wire rod. Carbon steel wire rod is widely used in construction and manufacturing. Carbon steel wire rod is mainly used for reinforcement of reinforced concrete and welded structure or reprocessed (roberts , nail, etc.) materials, especially used to produce wire drawing, welding electrode, nails, spring, electronic, precise machinery parts and so on.

Product Advantages:

OKorder's Carbon Steel Wire Rod are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Chemical Composition:

Please kindly find our chemistry of our material based on SAE1008B as below for your information

| Trademark | Rank | Chemical composition (quality score) % | ||||

| C | Si | Mn | S | P | ||

| ≤ | ≤ | ≤ | ||||

| Q195 | 0.06-0.12 | 0.30 | 0.25 | 0.050 | 0.045 | |

| Q235 | A | 0.14-0.22 | 0.30 | 0.30-0.65 | 0.050 | 0.045 |

| Q235 | B | 0.12-0.20 | 0.30 | 0.30-0.70 | 0.045 | 0.045 |

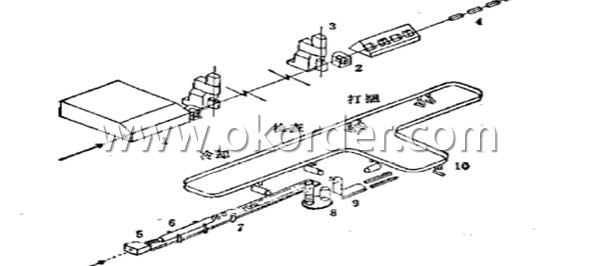

Production Process of Wire Rod

1-Furnace 2-Roughing Mill 3-High-speed Finishing Mill 4-Water-cooled Device 5-Coiling Device

6-Cooling Device 7-Chain Conveyer 8-Spool Collecting Device 9-Spool Down Device 10-Hook Conveyer

Packaging & Delivery of Wire Rod SAE1008B:

Packaging Detail: products are packed in coil and then shipped by container or bulk vessel

Each coil weight: 2-3MT

Delivery Detail: within 45 days after received deposit or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: CFR, CIF

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Image

- Q: What are the different surface cleaning methods used for steel wire rod?

- There are several surface cleaning methods commonly used for steel wire rod, including mechanical cleaning, chemical cleaning, and electrolytic cleaning. Mechanical cleaning involves using abrasive materials or equipment to physically remove dirt, rust, and other contaminants from the surface of the wire rod. Chemical cleaning involves using chemical solvents or cleaners to dissolve or loosen dirt and contaminants, which can then be rinsed or wiped away. Electrolytic cleaning utilizes an electrical current and an electrolyte solution to remove surface impurities through a process called electrochemical cleaning. Each method has its own advantages and is chosen based on the specific requirements and conditions of the steel wire rod.

- Q: What are the different types of steel wire rod coatings used for improved heat resistance?

- There are several different types of steel wire rod coatings that are commonly used to improve heat resistance. These coatings are applied to the surface of the steel wire rod to provide a protective barrier and enhance its ability to withstand high temperatures. One of the most common types of coating used for heat resistance is zinc. Zinc coatings, such as hot-dip galvanizing or zinc-aluminum alloy coatings, are effective in protecting the steel wire rod from heat and corrosion. The zinc coating forms a sacrificial layer that prevents the underlying steel from coming into contact with oxygen and moisture, thus reducing the risk of oxidation and corrosion. Another type of coating used for improved heat resistance is aluminum. Aluminum coatings are applied through a process called aluminum thermal spraying, where molten aluminum is sprayed onto the steel wire rod surface. This creates a durable and heat-resistant barrier that helps to maintain the integrity of the wire rod under high temperatures. In addition to zinc and aluminum coatings, there are also specialized coatings such as ceramic coatings and high-temperature resistant polymer coatings. Ceramic coatings are made from inorganic materials and provide excellent heat resistance, making them suitable for applications in extreme temperature environments. High-temperature resistant polymer coatings, on the other hand, are organic coatings that can withstand high temperatures without degradation. Overall, the different types of steel wire rod coatings used for improved heat resistance offer varying levels of protection and durability. The choice of coating depends on factors such as the specific application, operating temperature range, and desired level of heat resistance.

- Q: What are the common surface defects in steel wire rod?

- Some common surface defects in steel wire rods include scale, surface cracks, surface depressions, scratches, and rust spots.

- Q: How is steel wire rod used in the manufacturing of wire for oil and gas pipelines?

- Steel wire rod is a crucial component in the manufacturing of wire for oil and gas pipelines. It is first processed into wire through various steps such as hot rolling, cold drawing, and coating. This wire is then further processed and turned into strands or cables that are used to reinforce the pipelines, providing strength and durability. The steel wire rod's high tensile strength and corrosion resistance make it an ideal material for withstanding the harsh conditions of oil and gas pipelines, ensuring their safe and efficient operation.

- Q: How is steel wire rod used in the production of wire for cable trays?

- Steel wire rod is a crucial component in the production of wire for cable trays. The wire rod serves as the raw material for manufacturing the wire used in cable trays. The process starts with the wire rod being drawn through a series of dies to reduce its diameter and increase its length. This drawing process helps to refine the wire rod and improve its mechanical properties such as tensile strength and ductility. Once the wire rod has been drawn, it is then further processed to form the desired shape and size of wire for cable trays. This can involve additional processes like annealing to enhance its flexibility and resistance to deformation. The wire is then coated with a protective layer, such as zinc or PVC, to provide corrosion resistance and insulation properties. The wire produced from steel wire rod is specifically designed to meet the requirements of cable tray systems. It has high tensile strength to support heavy loads and resist bending, ensuring the cable tray can securely hold and protect electrical cables. The wire's smooth surface and uniform diameter facilitate easy installation and routing of cables within the tray, preventing any potential damage to the cables. In summary, steel wire rod plays a vital role in the production of wire for cable trays. It undergoes various processes to transform it into wire with the necessary mechanical properties and coatings. This wire is then used to construct cable trays that provide a reliable and efficient solution for organizing and protecting electrical cables in various industrial and commercial applications.

- Q: How is steel wire rod used in the production of wire products?

- Steel wire rod is an essential component in the production of wire products. Wire rod is a semi-finished product that is manufactured from steel billets through a rolling process. It is commonly used as a raw material in various industries to produce different types of wire products. One of the main applications of steel wire rod is in the production of steel wires. Steel wires are widely used in construction, automotive, electrical, and manufacturing industries for various purposes. For example, they are used for reinforcing concrete structures, making wire ropes, fencing, springs, nails, and screws. To produce wire products, the steel wire rod undergoes a series of manufacturing processes. Firstly, it is heated and then passed through a series of rolling mills to reduce its diameter and increase its length. This process, known as hot rolling, helps to enhance the mechanical properties of the wire rod. After hot rolling, the wire rod is cooled and then undergoes a pickling process to remove any scale or impurities from its surface. It is then drawn through a series of dies to further reduce its diameter and improve its surface finish. This process is called cold drawing and it helps to enhance the strength and ductility of the wire. Once the desired size and properties are achieved, the wire is either further processed or supplied as a finished product. Depending on the requirements, the wire can be subjected to additional processes such as heat treatment, coating, or surface finishing. These processes help to enhance the wire's performance and make it suitable for specific applications. In summary, steel wire rod is a crucial raw material in the production of wire products. Its versatility, strength, and ductility make it ideal for a wide range of applications. By undergoing various manufacturing processes, the wire rod is transformed into high-quality steel wires that are used in construction, automotive, electrical, and manufacturing industries.

- Q: What are the different sizes and dimensions of steel wire rod?

- Steel wire rods come in various sizes and dimensions, typically ranging from 5.5mm to 14mm in diameter. The length can vary, but commonly it is around 6 to 12 meters. These dimensions can be adjusted based on specific requirements and applications.

- Q: How is steel wire rod used in the manufacturing of wire for surgical sutures?

- Steel wire rod is an essential component in the manufacturing process of wire for surgical sutures. The wire rod undergoes several steps to transform it into the high-quality wire used in sutures. Firstly, the steel wire rod is carefully selected to ensure it meets the required specifications for surgical sutures. The rod is typically made of stainless steel, which provides excellent strength, durability, and corrosion resistance. Once the appropriate steel wire rod is chosen, it undergoes a series of processes to shape and refine it. The rod is drawn through a series of dies that progressively reduce its diameter to the desired size for surgical sutures. This process is known as wire drawing and is crucial in achieving the precise diameter and smooth surface required for sutures. After the wire has been drawn to the correct diameter, it is thoroughly cleaned and inspected for any defects or impurities. This ensures that the wire is free from contaminants that could compromise its integrity and safety for medical use. The next step involves coating the wire with a biocompatible material to enhance its performance and reduce any potential adverse reactions within the human body. This coating can be made from various materials, such as silicone or polymers, depending on the specific requirements of the surgical sutures. Once the wire has been coated, it is wound onto spools or bobbins, ready to be further processed into sutures. The wire is carefully handled and packaged in a sterile environment to maintain its cleanliness and prevent any contamination. Finally, the wire is sent to the suture manufacturing facility, where it is cut into precise lengths and further processed to create the final surgical sutures. These sutures are then packaged and sterilized, ready to be used in various surgical procedures. In summary, steel wire rod plays a critical role in the manufacturing of wire for surgical sutures. Through a series of processes, the rod is transformed into high-quality wire with the necessary diameter, surface finish, and biocompatible coating. This wire is then used to produce sterile and reliable sutures that are vital in various medical procedures.

- Q: How is steel wire rod processed into different shapes and sizes?

- Steel wire rod is processed into different shapes and sizes through a series of manufacturing processes. Initially, the wire rod is cleaned and descaled to remove any impurities. It is then heated and passed through a series of rolling mills, which gradually reduce its diameter while increasing its length. The wire is then cooled and coiled onto spools or cut into desired lengths. Further shaping and sizing can be achieved through processes like drawing, annealing, and coating, depending on the intended application of the wire.

- Q: What is the typical chemical composition of steel wire rod?

- The typical chemical composition of steel wire rod consists primarily of iron, carbon, and small amounts of other elements such as manganese, silicon, and sulfur.

Send your message to us

Hot Rolled High Quality Carbon Steel Wire Rod

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords