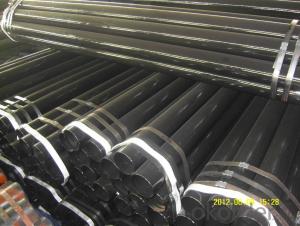

Carbon Steel ASTM A 106 Seamless Pipe with FBE coating

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Specification:

Iterm | Seamless steel pipe/tube | |

Size | OD:21.3-610mm WT:2.24-30.96mm | |

Length | 5.8-12m | |

Application | Usage for fluid transportation ,structure, and so on | |

Surface Treatment | 3PE/2PE,3PP/2PP,FBE,EPOXY COATING | |

Packing | Hexagon bundle with waterproof packing or as client's requirement | |

API | Standard | API 5L |

material | Gr.B, X42,X46,X52,X56,X60,X65,X70 | |

ASTM | Standard | ASTM A106, ASTM A53 |

material | A106(A B), A53(AB) | |

DIN | Standard | DIN1626,DIN17175,DIN1629 |

material | St37,st42,st35.8,st45-8,st45-4 | |

JIS | Standard | JISG 3454,JISG3456,JISG3461,JISG3455 |

material | STPG42,STB42,STS 42 | |

GB | Standard | GB 8163/8162 |

material | 20#,10#,45#,Q345,20Cr,40Cr,12CrMov | |

Payment terms | TT or L/C | |

Delivery time | Within 30 days after receive the prepayment by TT | |

ANTICORROSION STEEL PIPE SPECIFICATION :

1. 3PE COATING

3. FEB COATING

STANDARD: SY/T0315-97,SY/T0315-2005,CAN/CSA-Z245.20-M98,DIN30671,Q/CNPC38-2002

4. CEMENT MORTAR COATING

- Q: How does the price of steel pipes vary based on market demand?

- The price of steel pipes can vary based on market demand as it follows the basic economic principle of supply and demand. When the demand for steel pipes is high and the supply is limited, the price tends to increase. Conversely, when the demand is low and there is excess supply, the price tends to decrease. Factors such as infrastructure projects, industrial growth, and construction activities heavily influence the demand for steel pipes, thus impacting their price in the market.

- Q: How do steel pipes compare to other materials like PVC or copper?

- There are several advantages to using steel pipes compared to materials like PVC or copper. Firstly, steel pipes are known for their strength and durability. They can withstand high pressure and extreme temperatures without cracking or bending, making them ideal for heavy-duty applications such as industrial piping systems or underground installations. Secondly, steel pipes have excellent corrosion resistance. Unlike copper pipes that can corrode over time, steel pipes are typically coated with anti-corrosive materials like zinc or epoxy. This protective layer prevents rust and ensures a longer lifespan for the pipes. Furthermore, steel pipes offer superior fire resistance compared to PVC or copper. They are non-combustible and can withstand high temperatures for extended periods without deforming or releasing toxic gases. This makes steel pipes a safer option for applications where fire hazards are a concern. In terms of cost, while steel pipes may initially be more expensive than PVC, they offer better long-term value due to their durability and longevity. On the other hand, copper pipes can be quite expensive and are susceptible to theft due to their scrap value. Lastly, steel pipes are highly versatile and can be used in various applications such as water supply, sewage systems, gas pipelines, and oil refineries. They can handle high volumes of fluid with ease and are resistant to external factors like UV rays or physical impacts. Overall, steel pipes are a reliable and efficient choice for many industries and applications, offering strength, durability, corrosion resistance, fire resistance, and versatility that sets them apart from materials like PVC or copper.

- Q: Difference between seamless steel pipe and welded pipe

- Seamless steel tubes are made of high quality carbon or alloy steel. They are hot-rolled and cold-rolled (drawn).The welded pipe is rolled into the steel tubular to sew or spiral seam welded in the manufacturing method, and is divided into low pressure fluid delivery with welded steel pipe, spiral welded steel pipe, welded steel pipe, welded pipe roll etc..

- Q: How are steel pipes used in the manufacturing of food processing machinery and equipment?

- Steel pipes are commonly used in the manufacturing of food processing machinery and equipment due to their durability, corrosion resistance, and high strength. These pipes are used for various purposes such as fluid transportation, steam generation, and structural support in the machinery. They are also crucial for conveying liquids, gases, and other food ingredients safely and hygienically throughout the manufacturing process. Additionally, steel pipes can withstand high temperatures and pressures, making them ideal for applications like sterilization, pasteurization, and cooking in food processing machinery.

- Q: How are steel pipes handled and transported safely?

- Steel pipes are handled and transported safely through a combination of proper lifting and handling techniques, secure packaging, and appropriate transportation equipment. Before transportation, pipes are bundled, strapped, or put into crates to prevent any movement or damage during transit. Special lifting equipment such as cranes or forklifts are used to handle them, ensuring that proper weight distribution and balance are maintained. Additionally, securing the pipes to flatbed trucks or using specialized pipe carriers prevents them from rolling or shifting during transportation. Regular inspections, adherence to safety regulations, and trained personnel play a vital role in ensuring the safe handling and transportation of steel pipes.

- Q: Can steel pipes be used for natural gas processing plants?

- Yes, steel pipes can be used for natural gas processing plants. Steel pipes are commonly used in the oil and gas industry due to their high strength, durability, and resistance to corrosion. They can safely transport natural gas and are capable of withstanding the high pressure and temperature conditions typically found in processing plants.

- Q: What are the different types of steel pipe fittings for plumbing systems?

- Some common types of steel pipe fittings used in plumbing systems include elbows, tees, unions, couplings, reducers, and caps. Elbows are used to change the direction of the pipe, while tees allow for branching off into multiple directions. Unions are used to join two pipes together, couplings are used to connect two pipes of the same diameter, and reducers are used to connect pipes of different diameters. Caps are used to seal the end of a pipe.

- Q: What are steel pipes?

- Steel pipes are cylindrical tubes made from steel that are used for various purposes, such as transporting fluids and gases, structural applications, and construction projects. They are known for their durability, strength, and resistance to corrosion, making them a popular choice in industries such as oil and gas, plumbing, and infrastructure development.

- Q: Can steel pipes be used for underground water supply networks?

- Yes, steel pipes can be used for underground water supply networks. Steel pipes are commonly used for underground water supply networks due to their durability, strength, and resistance to corrosion. They can withstand high pressure and are able to handle the weight of the soil and other external forces. Additionally, steel pipes are available in various sizes and can be easily welded, making them suitable for different water supply system requirements. However, it is important to take into consideration factors such as the quality of the soil, the presence of chemicals or corrosive substances, and the need for regular maintenance to ensure the longevity and efficiency of the steel pipes in underground water supply networks.

- Q: How are steel pipes used in the manufacturing of fire sprinkler systems?

- Steel pipes are commonly used in the manufacturing of fire sprinkler systems due to their durability, strength, and resistance to high temperatures. These pipes are used to transport pressurized water or fire retardant throughout the sprinkler system, ensuring quick and effective fire suppression. The steel pipes are installed strategically throughout the building, delivering water to sprinkler heads that are activated when heat is detected. Overall, steel pipes play a crucial role in the safe and efficient operation of fire sprinkler systems, protecting lives and property from the devastating effects of fires.

Send your message to us

Carbon Steel ASTM A 106 Seamless Pipe with FBE coating

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords