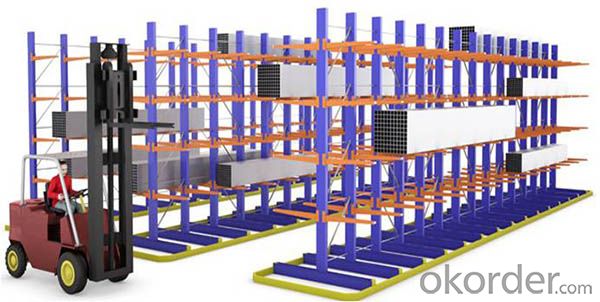

Cantilever Type Pallet Racking System for Warehouse

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

It's called cantilever racking system. The cantilever rack is used for long material, round goods, plates and pipes.

Cantilever rack is particularly used for specific products and easy for storage operation and convenient for warehouse.

The cantilever rack could for machinery manufacture industry and building material market.

Feature:

· For Small space

· It's easy for management.

· With good vision.

Images:

Specification:

Length | less than 3000mm |

Width | less than 1500mm |

Height | less than 6000mm |

Loading capacity | 500-1000KG |

FAQ:

What is cantilever pallet racking system?

Cantilever pallet racking system is used for long goods and have good vision for small warehouse of limited height.

How is quality guaranteed?

The production use professional roll forming technology and material of steel for production have strict test.

How about the project installation?

Drawing for installation is provided for users. We also could send engineers to users's spot to carry out installation for project.

- Q: How to strengthen the integration and construction of logistics infrastructure

- Specialized facilities. Refers to a specific area, because of its downstream business relations and production related enterprises are relatively concentrated, or as the regional freight is more concentrated in the node area, need to provide specialized facilities on the requirements of logistics management, including logistics park, logistics center and distribution center, so that in a specific area to achieve supply chain centralized management the function of.

- Q: How to do the warehouse logistics supervisor?

- Make reasonable operation procedure. After the above of a warehouse, goods storage and storage function, the amount of work and other warehouse problems often appear to understand, to need the operation is carried out in the warehouse and work out a reasonable process.

- Q: What are the commonly used automation equipment in warehouse logistics?

- Such as the commonly used transport equipment, the car these

- Q: Question: what is the nature of logistics warehousing?

- Productive logistics land generally includes the production enterprises directly used for material storage, transit, distribution, distribution, transportation, loading and unloading, as well as the corresponding ancillary facilities, and its nature can be identified as industrial storage land;

- Q: How to classify logistics facilities and equipment is more reasonable and scientific

- The handling and transportation activities permeate all aspects of the logistics industry, which determines the smooth progress of the logistics industry. The loading system is divided into two parts from the big side to the loading and unloading machinery, and the two to the transportation machinery. Handling machinery include: cranes, forklifts, container handling, handling and pallet make-up. Transport machinery includes all kinds of heavy-duty vehicles for road transportation, trains for railway transportation, ships for water transport, aircraft for air transport, pipelines for pipeline transportation, and so on. With the development of logistics information, network and system, the computer plays an important role in the logistics management. Communication equipment generally include: telephone, telegraph, electronic commerce, wireless transmitter tower, etc.. Computers and communication equipment have linked the life, culture, politics and economy of the whole world, shorten the distance between time and space, and enable people to know the environment, information and change in a timely and accurate way.

- Q: What are the categories of logistics?

- Logistics in the production field runs through the whole process of production. The whole process of production from raw material procurement, it requires the corresponding supply logistics activities, namely the purchase needed for the production of materials; between the production of the process, the logistics process of the raw materials and semi-finished products, namely the so-called production logistics; recovery of surplus material, reusable materials. Is the so-called waste recycling logistics; logistics needs is the disposal of waste.

- Q: What brands of operating equipment are used in the major logistics and express companies in China?

- Many express companies are designed for special companies. They include roller conveyors, electronic packages, sewing racks, sewing machines, wireless guns, trays and the like

- Q: What aspects of logistics and warehousing management?

- Bonded warehouses are the places where the goods are imported under the supervision of the customs and approved by the customs. Bonded warehouse storage of goods: (1) import formalities postponed it includes consignment maintenance of imported spare parts, duty-free goods, bonded production materials market needed to be sold goods etc.. (2) goods that need to be importedSome of the goods are not suitable for the sales in the importing country, the need for packaging and processing, can be processed in the bonded warehouse, to meet the requirements of the importing country, and domestic tax, does not comply with the tax refund or transfer to other countries. (3) spare parts needed for the processing of spare parts (processing, assembling and feeding processing) needed for processing trade (processing, assembly and feed processing) can be stored in bonded warehouses. (4) commodities that transit transit goods include foreign stocks, temporary storage, temporary goods, entrepot goods, fuel and spare parts used by international navigation ships, duty-free commodities to be sold at duty-free shops, etc..

- Q: What are the third party logistics? What are the advantages and disadvantages?

- If you are a supplier of raw materials, and your raw material needs customers need to quickly replenish the supply, you must have a regional warehouse. The 3PL warehouse service, you can meet the needs of customers, not necessarily because of the construction of new facilities or long-term lease and transferred to capital and operating flexibility is limited. If you end product suppliers, the use of 3PL can also provide customers with more than the end of their own to provide their diverse range of services, to bring more value-added customers, so that customer satisfaction improved.

- Q: What shelves are there in the logistics equipment?

- The so-called logistics equipment is necessary for the logistics activities of complete sets of buildings and artifacts, organizations involved in a variety of physical flow of mechanical equipment, transport, storage facilities, station, computer and communication equipment.

Send your message to us

Cantilever Type Pallet Racking System for Warehouse

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords