Punch Die Racking Systems for Warehouses

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Mould pallet racking shelves is kind of storage system and is designed for module storage. Module pallet rack is assemblied by upright, slide rail, drawer, positioning device, etc. Mould pallet racking shelves have stable structure and safe feature, usually in a line for usage.

Module pallet rack makes it easy and convenient for punching die storage.

Feature:

· Professional

· Good quality

· Long life

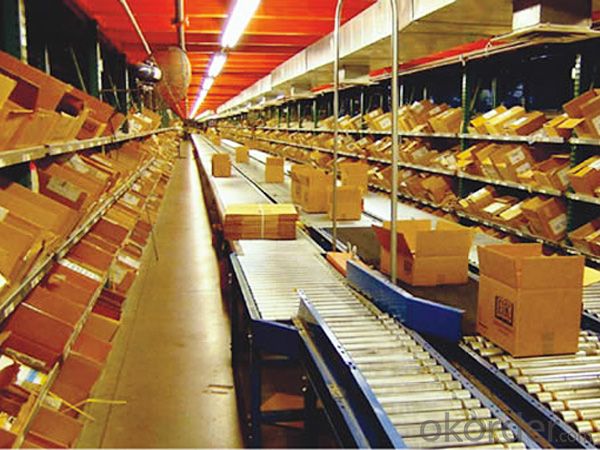

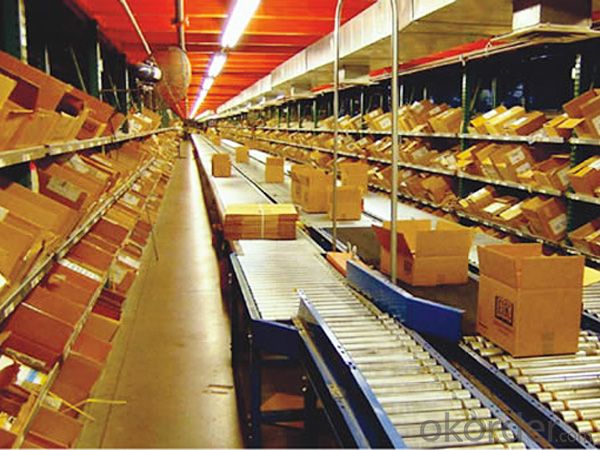

Images:

Specification:

loading | 400-800KG |

Heavy loading | 900-1500KG |

FAQ:

What is mould pallet racking shelves ?

Module pallet rack is designed and used for punching die storage

How is quality guaranteed?

The production uses professional roll forming technology.

How about the installation?

We could send engineers to users's spot to carry out installation.

- Q: What are the basic principles of warehousing?

- The "warehouse" also known as the warehouse, store items for buildings and facilities, for housing construction, large containers, caves or specific sites, is to store and protect the function of items; "reservoir" said storage for use, storage, storage, delivery and use of means, when applied to tangible items also for storage. "Warehousing" is the act of using a warehouse to store and store items that are not immediately available. In short, warehousing is the act of storing goods in a particular place.

- Q: What are the logistics and warehousing equipment? The more, the better

- Mezzanine shelves, cantilever shelves, through shelves, hydraulic cars, forklifts and so on

- Q: What are the advantages of automated warehousing and its role in logistics systems?

- The loss caused by the quality of operation is greater. On the one hand is the traditional plane warehouse logistics automation level is low, the goods into the library is the basic manual use of forklift operation, due to improper operation will cause artificial goods collision loss; on the other hand is because of the wrong operation or cost error caused by the error distribution, especially the distribution of medicines, will cause more serious consequences.

- Q: What are the commonly used automation equipment in warehouse logistics?

- Handheld scanning terminal, etc.. These generally need to work with standardized logistics packaging, such as shelves, materials, boxes, etc..

- Q: Logistics warehousing problems?

- The basic functions of logistics include transportation, warehousing, loading and unloading, packaging, information and other five functions:I. transportation: for the purpose of moving the space, creating the connection between the producer and the consumer, so transportation is the core of logistics, and the early logistics management often delivers the logistics as a whole.Two. Storage: a kind of goods circulation storage, can be divided into long-term storage and relay storage. Storage is the operation that overcomes the time factor. A good storage environment can create the limitation of the use of the goods, and through the planning, storage and storage time, the profits can be effectively improved.Three, loading and unloading goods storage: between between transportation and warehousing process is mainly unloading work. The proper use of machinery and equipment, automation and unmanned operation is the major factor contributing to the reduction of handling costs.Four, packaging: can be divided into commodity packaging and industrial packaging. Commodity packaging can make it convenient for consumers to buy all kinds of goods, while industrial packaging is convenient for transportation. The modernization of packaging can create the added value of products, and can use the method of classified packaging to achieve the proper transportation and sale of products.Five, information: that is, computerized processing, transportation, storage, loading and unloading, packaging and other functions, can make logistics more systematic and efficient. The concept of logistics information system due to the personal computer and the popularization of the Internet, the effective management of production, transportation, storage, handling, packaging and delivery process of the information system can promote the logistics industry, to save labor and efficiency goals.

- Q: What are the main differences between the electricity supplier warehouse and the traditional warehouse?

- Single SKU inventory is low. Compared with the traditional retail stores, e-commerce sales platform without traditional space limit, so in order to attract and meet the needs of more customers, sales of electricity supplier SKU to more comprehensive, such as Amazon and dangdang etc. there are hundreds of thousands, millions of SKU. But because the storage space can not be unlimited expansion, how to put more SKU in the limited storage space, you need each SKU less than the amount of goods. As a result, the storage units in the electricity supplier warehousing logistics are dominated by boxes instead of traditional pallets. From the choice of storage equipment, the main choice of box shelves, such as shelf shelves or medium-sized shelves, rather than pallet shelves. In the aspect of operation strategy, most storage and picking are one, and a small amount of SKU distribute storage and picking space, and there is a replenishment operation from storage to picking.

- Q: What are the categories of logistics?

- Logistics in the production field runs through the whole process of production. The whole process of production from raw material procurement, it requires the corresponding supply logistics activities, namely the purchase needed for the production of materials; between the production of the process, the logistics process of the raw materials and semi-finished products, namely the so-called production logistics; recovery of surplus material, reusable materials. Is the so-called waste recycling logistics; logistics needs is the disposal of waste.

- Q: What brands of operating equipment are used in the major logistics and express companies in China?

- Many express companies are designed for special companies. They include roller conveyors, electronic packages, sewing racks, sewing machines, wireless guns, trays and the like

- Q: Storage facilities and equipment is not perfect, what?

- In the future, warehousing centres will be reduced in number, but the number of goods at each center will increase. As a result, the distribution centers are larger on the one hand, and on the other hand, more orders are being processed daily. This means that the speed of the shipment is increased and the receipt, placement, picking and shipment are increased. This trend will put forward higher requirements for material handling systems, and will have a significant impact on forklifts and conveyor belts.

- Q: What is the storage fee?

- The storage of goods cost mainly refers to the expenses of goods, which is a part of storage facilities and equipment investment, the other part is the living labor or physical labor storage operation in consumption, including wages and energy consumption etc..

Send your message to us

Punch Die Racking Systems for Warehouses

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords