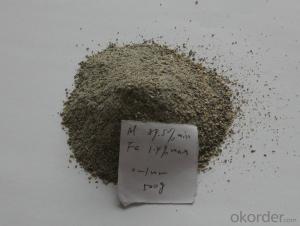

High Purity Al2O3 Calcined Bauxite Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

85 calcined bauxite

Item | Calcined Bauxite High Purity of Al2O3 |

| Product Description | Calcined bauxite is one of the principal ore of aluminum. Calcined bauxite contains hydrous aluminum oxides and aluminum hydroxides, formed through the laterization of aluminous rocks in tropical and subtropical areas .calcined bauxite is obtained by calcining (heating)superior grade bauxite at high temperature (from 85OC to 1600C) .this removes moisture thereby increasing the alumina content. compared to an alumina content of about 57%to 58%in raw bauxite, calcined bauxite has an alumina content of 84%to88%.the heating is carried out in rotary kilns. |

Size | 0-1mm,1-3mm,3-5mm,200mesh,325mesh,or as buyer's request. |

| Application | 1.Aluminium metallurgy. 2.Precision casting/Investment casting: bauxite grog fines can be made into mold for precision casting. 3.Refractory: high alumina bauxite's refractoriness can reach 1780°C. It is charactered by good chemical stability and mechanical performance.( low Fe2O3) 4.Aluminium silicate refractory fiber: The high alumina bauxite grog can melt under2000°C-2200°C in the electric arc furnace. After a series of processing, it can become aluminium silicate refractory fiber, which can be made into fiber blanket,plate,cloth. 5.Mixing magnesia and bauxite grog with binders to pour the molten steel ladle for better overall lining performance. 6.Producing bauxite cement. 7.Abrasives. 8.Ceramics industry. 9.Chemistry industry for all kinds of aluminium compound. |

| Chemical Composition | GradeAL2O3FE2O3TIO2K2O+Na2OCaO+MgOBulk density7068min≤2.0≤4.0≤0.6≤0.6≥2.757573min≤2.0≤4.0≤0.6≤0.6≥2.758080min≤2.0≤4.0≤0.5≤0.5≥3.258585min≤2.0≤4.0≤0.4≤0.4≥3.0088 87.5min≤1.6≤4.0≤0.4≤0.4≥3.20 |

| Our Service | 1.We can offer you the customer size services. 2.We can offer you the best quanlity and price. 3.We can offer you the related test report,both at factory and the third party. 4.Packaging: 25KG per bag or as client's requirement. 5.We have sufficient manufacturing capability to delivery the goods safely and in time. |

| Our Advantage | 1.24 Years experience of Calcined Bauxite manufacturing and exporting. 2.Our factory is equited with advanced machine,automatic production line, we are in a good position to produce customers size product in large scale with low cost. thus,provide low priced goods. 3.Self-owed mine fo production capacity over 5000MT per month. 4.Professional export team and skilled workers, we are in a good position to serve our customers to the best of our ability. 5.Strictly quality contol at our factory and third party quality inspection before shipment. 6.Cargoes together with container sales service available. 7.Full experience of large numbers containers loading in Chinese sea port. 8.Packing with pallet as buyer's special request. 9.Fast shipment by reputed shipping line. 10.Cargoes photo before and after loading into container. 11.Professional service team keep customers informed from delivery to discharge. |

- Q: Who know what kind of fire shutter fire rating are there?

- There is no national standard for fire protection performance of fire roller shutter in China, and now the executive standard of GB14102-2005 "fire shutter": F1, fire-resistant time 1.50h; F2, fire-resistant time 2.00h; F3, fire-resistant time 3.00h; F4, fire-resistant time was 4.00h before the national standards of fire shutter grading is introduced, expert advice that fire resistance test be made according to national standard, to reach back fire surface temperature rise requirements, if the refractory limit is greater than or equal to 3.0h, it is said to be super fire shutter, if test not inspect unexposed surface temperature rise as a judgement of the conditions, the door is referred to as ordinary fire shutter doors. I hope my answer can help you

- Q: Does anyone know what kind of light fireproof materials are there?

- 二, 1, Gypsum plaster board With the building plaster as main raw material, gypsum plaster board is a kind of processed plate made by a special board for protective with an addition of additives and fibers as board core. Gypsum plaster board is characterized by light weight, sound insulation, heat insulation, strong processing performance and simple construction method. 2, Gypsum block Gypsum block is a kind of lightweight building gypsum product which is mainly made of building gypsum, and by adding water, stirring, casting and drying. During the process, , the fiber reinforced materials or light aggregates are allowed in, and the foaming agent can also be added. It has many advantages, such as sound insulation and fire prevention, convenient construction and so on. It is a kind of new and healthy wall material which produces low carbon, enhances environmental protection, and caters to the the times. 3, Fly ash brick is a new type of wall material, and bulk density is one of the main technical indexes. The weight of bulk density can be controlled according to the need of construction and adjustment of technical formula. The dry bulk density of the fly ash brick is about 1540 to 1640 kg / m 3, slightly lighter than the clay brick (1601800 kg /m 3). The flexural and compressive strength of fly ash brick is mainly determined by the production process, the formula and the hydrothermal synthesis reaction mode as well as the need of construction. According to the standards of architectural material industry (JC239 - 2001) released by People's Republic of China, the average value of the flexural strength is 2.5 ~ 6.2Mpa, compressive strength is between 10 ~ 30Mpa. I hope this will be helpful to you

- Q: What is the fire endurance of ceramsite concrete blocks?

- The heat conductivity coefficient of grade 800 hollow building blocks in ceramsite concrete is 0.23 and fire endurance is 4h. Ceramsite concrete has strong construction adaptability. It can not only compound concrete material with different unit weight and strength(It changes with the structure of thermal insulation or bearing structure) according to the different purposes and functions of buildings, but also is easy to construct. It is suitable for industrial production of a variety of construction methods. It can not only make all types of components(board, block, girder, column, etc) by using production process, but also can use mechanization construction of cast-in-place. The strong adaptability of construction of ceramsite concrete is not comparable to any other lightweight building materials(such as air-entrapping, etc.).

- Q: What are the new refractories? What are the features? How about their application and development?

- In metallurgy, in what position should it be used, in order to make the best. Answers are as following. In iron, steelmaking or converter. When questioning, pay attention to the ways. Answers: Try to use synthetic refractory materials.

- Q: Fire rating of decoration materials

- code for fire protection design of buildings

- Q: What materials are needed to make the amorphous refractory bricks?

- The amorphous refractory brick is composed of a certain proportion of aggregate and powder, a binder and an additive, and it can be directly used or used after allocation with some liquids. The amorphous refractory brick is a new type of refractory material without calcination, its refractoriness is below 1580℃.There is a wide variety of refractory materials. According to the production method and usage thereof can be divided into concrete, castable, plastic refractory, ramming refractory, gunning mix, sling refractory, coating material, dry ramming mix , fire clay, and all kinds of repairing mass(Asphalt combined with large surface charge compensation, Martin also belongs to the shape of the amorphous refractory material).

- Q: I would like to know if there is any requirement for refractories in the crucible type high-frequency smelting furnace Worry! I hope you can help me! This time!

- High enough for high temperature resistance. Refractory materials for crucibles shall be subjected to a high temperature greater than 1700 DEG C and the softening temperature shall be greater than 1650 DEG c;

- Q: What are the main characteristics of the sic refractories?

- The physical properties of SiC refractories include structural properties, thermal properties, mechanical properties, usability and job performance. The structural properties of refractory include porosity, bulk density, water absorption, air permeability, an the distribution of pore size. The thermal properties of refractory include thermal conductivity, thermal expansion coefficient, specific heat, heat capacity, thermal diffusivity, and thermal emission rate. The mechanical properties of refractories include withstand voltage strength, tensile strength, anti bending strength, torsional strength, shear strength, impact strength, abrasion resistance, creep resistance, adhesive strength, and elasticity modulus. The usability of refractories include refractoriness, load softening temperature, linear?change?on?reheating, thermal shock resistant performance, slag resistance, acid resistance, alkali resistance, hydration resistance, corrosion resistance to CO, conductivity, and inoxidizability.

- Q: What is the fireproofing requirements of external wall thermal insulation materials?

- According to the "building external wall insulation fire barrier zone technical regulations" to be published: it is not less than the level B2. But before the procedure was published, it should be strictly implemented the document, level A is the best, I hope to help you, hope to adopt

- Q: who knows the technology of fireproofing material?

- 1, dealing mould, scrape and clean the thick liquid on the surface of mould with tin-coated steel scraper blade or plaster tool. 2, adjust laminator, according to the thickness of fireproof?panel, adjust each roller, keep them parallel. 3, ingredient, according to the requirements of recipe, stir the raw materials uniform with agitator. (usually we should add bittern firstly, stir it with modifying agent for 5 minutes, then add filler and stir for 2-3 minutes, finally add grogs and stir it to uniform) note: the stirring speed should be kept in 60-80 r/min. 4, place the cloth, place a layer of non-woven fabric and two layers of glass fiber fabric (mechanical spread fabric). 5, flitch, place the materials after compounding and stirring into stop gauge of laminator, then you can start up and produce continuously, it's finished product after finishing. note: the distance between two templates is 2-4mm.

Send your message to us

High Purity Al2O3 Calcined Bauxite Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords