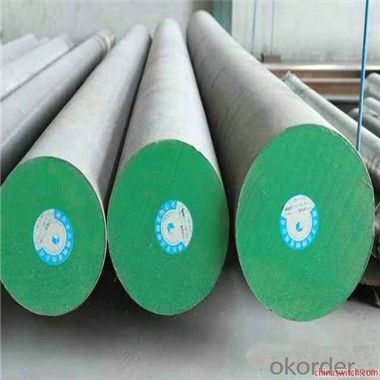

C20 AISI1020 S20C S22C 1023 C22 CK22 1.0402 1.1151 Carbon Steel Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

C20 AISI1020 S20C S22C 1023 C22 CK22 1.0402 1.1151 Carbon Steel Bar

Hardness:156HB

Tensile strength:410MPA

Yield strength: 245MPA

elogation:25% Reduction of area:55%

AKV(impact value):54J

Material: | Carbon Steel Round Bar SAE 1020 |

Diameter: | 16mm-300mm |

Length: | 3000mm-12000mm Straightness: 3mm/M max |

Process: | EAF + LF + VD + Forged + Heat Treatment (optional) |

Delivery condition: | Hot forged +Rough machined (black surface after Q/T)+ Turned (optional) |

Delivery Time: | 30days after confirmation |

MOQ: | 20 tons |

Heat treatment: | Normalized / Annealed / Quenched / tempered |

Technical Data: | According to the customer's requirement of Chemical Composition, Physical Properties and Mechanical Testing |

Marking: | Grade, heat NO. length will be stamped one each bar with required color |

Payment: | 30% advance by T\T; Balance pay before the shipment against shipping documents or irrevocable LC at sight |

Application: | Statically and dynamically stressed components for vehicles, engines and machines. For parts of larger cross-sections, crankshafts, gears. |

Test | The mill test certificate shall show the chemical composition, and itis guaranteed that the chemical composition shall be within the limitstipulated in the contract. |

- Q: What is the difference between a solid steel round bar and a hollow steel round bar?

- A solid steel round bar is a cylindrical metal rod with a consistent diameter along its entire length. It is made of solid steel and does not have any empty space inside. On the other hand, a hollow steel round bar also has a cylindrical shape but contains an empty space within its center. The size of this empty space can vary depending on the design and purpose of the bar. The main difference between the two lies in their structural integrity and weight-bearing capacity. A solid steel round bar offers greater strength and stability compared to a hollow steel round bar. This is because the solid bar is made of continuous steel material, making it more resistant to pressure-induced bending, twisting, or deformations. It is commonly used in industries that require high strength and durability, such as construction, engineering, and manufacturing. In contrast, a hollow steel round bar may have reduced strength and load-bearing capacity due to the empty space inside. However, the hollow design provides certain benefits in terms of weight, cost, and flexibility. The hollow space reduces the overall weight of the bar, making it suitable for applications where weight is a critical factor, such as aerospace or automotive industries. Moreover, the hollow space can be utilized for various purposes, such as passing electrical wires or fluids, providing ventilation, or reducing material costs by using less steel. Ultimately, the choice between a solid steel round bar and a hollow steel round bar depends on the specific requirements of the application. If strength and stability are crucial, a solid bar is the preferred choice. In contrast, if weight reduction, cost-efficiency, or additional functionality is desired, a hollow bar may be more suitable.

- Q: How are steel round bars used in the construction of pipelines?

- Steel round bars are commonly used in the construction of pipelines as they provide strength and durability to withstand the high pressure and external forces exerted on the pipelines. These bars are often used as reinforcement within the pipeline structure, ensuring its stability and preventing deformation or collapse. Additionally, steel round bars are employed for welding purposes, connecting different sections of the pipeline together, further enhancing its structural integrity.

- Q: What are the different grades of carbon steel round bars for structural applications?

- The different grades of carbon steel round bars commonly used for structural applications include ASTM A36, ASTM A572, and ASTM A992.

- Q: Can steel round bars be used in manufacturing equipment?

- Yes, steel round bars can be used in manufacturing equipment. Steel round bars are commonly used in the manufacturing industry due to their various advantageous properties. They are known for their high strength, durability, and resistance to wear and tear. These properties make steel round bars ideal for use in heavy-duty machinery and equipment. They can be used to manufacture components such as shafts, axles, pins, and gears, which are crucial for the proper functioning of machinery. Additionally, steel round bars can be easily machined, welded, and formed into various shapes, making them versatile for use in different manufacturing applications. Overall, steel round bars are a reliable and widely used material in the manufacturing industry for the construction of equipment.

- Q: What are the different types of steel alloy compositions used for round bars?

- There are several different types of steel alloy compositions used for round bars, including carbon steel, stainless steel, tool steel, and alloy steel. Each type has its own unique properties and characteristics that make it suitable for specific applications.

- Q: What are the advantages of using chromium-vanadium alloy steel round bars?

- Using chromium-vanadium alloy steel round bars has several advantages: 1. Exceptional Strength and Hardness: Chromium-vanadium alloy steel is renowned for its high strength and hardness. It possesses a strong tensile strength, making it ideal for heavy-duty applications and resistance against wear and tear. 2. Enhanced Durability: The incorporation of chromium and vanadium elements improves the durability of the alloy steel round bars. It offers excellent resistance to corrosion, oxidation, and high temperatures, making it perfect for harsh environments. 3. Versatility in Applications: Chromium-vanadium alloy steel round bars provide versatility in various applications. They are suitable for manufacturing tools, springs, gears, and other components requiring strength and durability. This alloy steel's versatility makes it highly favored in industries like automotive, aerospace, and construction. 4. Convenient Machinability: Chromium-vanadium alloy steel is relatively easy to machine and work with, offering convenience to manufacturers. It can be easily shaped, cut, and formed into desired sizes and shapes without compromising its mechanical properties. 5. Cost-Effective Option: Despite its exceptional properties, chromium-vanadium alloy steel round bars tend to be cost-effective when compared to other high-performance alloys. Hence, it is a popular choice for industries that require strong and durable materials within their budget. 6. Exceptional Fatigue Resistance: Chromium-vanadium alloy steel demonstrates exceptional fatigue resistance, making it suitable for applications involving repetitive stress or cyclic loading. It can withstand repeated use and maintain its structural integrity over an extended period. In conclusion, chromium-vanadium alloy steel round bars offer a combination of high strength, enhanced durability, versatility, and cost-effectiveness. These advantages make it the preferred material choice for various industrial applications where reliability and performance are of utmost importance.

- Q: How do steel round bars perform under bending or flexing forces?

- Steel round bars exhibit excellent performance when subjected to bending or flexing forces due to their exceptional tensile strength and ductility. Their ability to resist deformation and retain their shape makes them highly suitable for various applications in construction, manufacturing, and engineering. Moreover, the combination of high strength and ductility enables these bars to evenly distribute and absorb applied loads, thereby minimizing the risk of failure or breakage. To further enhance the behavior of steel round bars under bending or flexing forces, several factors come into play, including alloy composition, heat treatment, and manufacturing processes. Different grades of steel offer varying levels of strength, toughness, and bending resistance. Additionally, heat treatment techniques such as quenching and tempering can significantly enhance the bars' mechanical properties, rendering them more resistant to bending and flexing. Nevertheless, it is crucial to acknowledge that excessive bending or flexing can result in permanent deformation or failure of steel round bars. Overloading or repeatedly subjecting the material to bending beyond its limits can lead to stress concentrations, microcracks, or even fractures. Consequently, it is of utmost importance to establish appropriate bending limits and ensure proper design and installation to uphold the structural integrity and safety of steel round bars when exposed to bending or flexing forces.

- Q: Are lightning checks required for galvanized steel, flat steel and round steel?

- The corrosion resistance of cold galvanizing is not as good as that of hot-dip galvanizing. It is used as lightning protection and grounding material. It is corroded quickly, and the grounding resistance is raised rapidly. It exceeds the required resistance.

- Q: Three - grade thread Phi 10 steel can replace a grade Phi 12 round bar? Which elder knows, trouble pointing.

- According to the substitution of steel bars, one method, equal strength substitution, equal area substitution and equal root substitution can be obtained by substitution. Three grades of thread Phi 10, steel replaced by a grade Phi 12 of the round steel, I think it may appear: does not meet the minimum reinforcement ratio requirements and reinforcement construction regulations. Don't change it for the best. But must change, must pass the design.

- Q: Can steel round bars be cut to custom lengths?

- Yes, steel round bars can be cut to custom lengths.

Send your message to us

C20 AISI1020 S20C S22C 1023 C22 CK22 1.0402 1.1151 Carbon Steel Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords