C Channel Steel (Height: 50–400mm)

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 42000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

C Channel Steel (Height: 50–400mm)

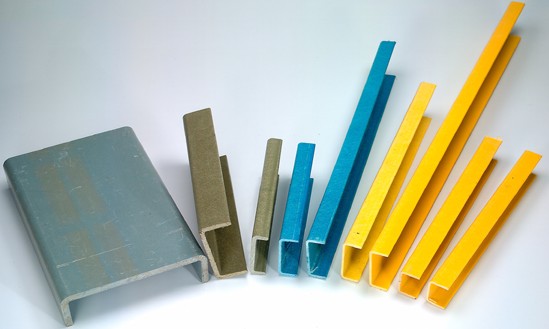

OKorder is offering high quality C Channel Steel (Height: 50–400mm) at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

C Channel Steel (Height: 50–400mm) is ideal for use in the construction of ships, vessels and other steel structures.

Product Advantages:

OKorder's Channel Steel is durable, strong, and resists corrosion. Additionally, our steel is easily assembled with the assistance of trained engineers.

Main Product Features:

· Short construction period

· Strong

· Experienced engineer assistance

· ISO9001 & SGS certification

· Easy to assemble and dismantle

· Can be recycled and reused

Product Specifications:

Ordinary Model

Height: | 50 – 400mm |

Thickness: | 4.5 – 14.5mm |

Surface: | Painted, Galvanized, As per customer request |

Length: | As per customer request |

Size: | 50 X 37 X 4.5mm—400 X 104 X 14.5mm |

Punch: | Can be punched as per customer request |

Material: | Q195 / Q235 / Q215 / Q345 / SS400 / S235JR, A36, SS400, SS540 ASTM A36 |

Light Model

Height: | 50 – 400mm |

Thickness: | 4.4 – 8.0mm |

Surface: | Painted, Galvanized, As per customer request |

Length: | As per customer request |

Size: | 50 X 32 X 4.4mm – 400 X 115 X 8.0mm . |

Punch: | Can be punched as per customer request |

Material: | Q195 / Q235 / Q215 / Q345 / SS400 / S235JR, A36, SS400, SS540 ASTM A36 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: How do steel channels contribute to the overall safety of a structure?

- Steel channels contribute to the overall safety of a structure by providing structural support and stability. They are used to reinforce beams, columns, and frameworks, enhancing the load-bearing capacity of the structure. Additionally, steel channels can help distribute and redirect forces, such as those caused by wind or seismic activity, reducing the risk of structural failure. Their high strength and durability make them resistant to deformation and ensure long-term stability, further enhancing the safety of the entire structure.

- Q: The above four should be all types of steel, but what is the relationship between H steel and I-beam, C section steel and channel steel?Is the I-beam included in the H section, or is it all the same?

- First of all, C steel after cold bending of hot coil and high strength, good tenacity, and channel production can save 30% compared to the same intensity of raw materials, is a direct channel by steel companies, the thickness is greater, it is groove shaped cross section.?Second, C steel is usually used for steel structure building wall beam, beam, bracket or other building components, widely used in the activity room, also can be used in machinery manufacturing industry. Channel steel is mainly used in building structures, vehicle manufacturing, and other industrial structures, often with the use of i-beam. Although the two steels are used in building structures, they are used in different ways.

- Q: What is the standard length of steel channels?

- The standard length of steel channels can vary depending on the specific industry and application. However, in general, steel channels are commonly available in standard lengths of 20 feet or 6 meters. These lengths are often chosen to facilitate easy transportation and handling, as well as to align with common building and construction practices. It is important to note that custom lengths can also be obtained based on specific project requirements, but the standard length of 20 feet or 6 meters is widely used and readily available in the market.

- Q: How do steel channels perform in extreme weather conditions?

- Steel channels perform well in extreme weather conditions due to their strong and durable nature. They are designed to withstand high winds, heavy snow loads, and extreme temperatures. The structural integrity of steel channels allows them to resist bending, warping, or cracking, which makes them ideal for withstanding the forces exerted by severe weather conditions. Additionally, steel channels are highly resistant to corrosion, which is crucial in areas prone to high humidity or exposure to saltwater. This resistance ensures that the steel channels will remain strong and intact even in harsh weather environments. Overall, steel channels are a reliable and dependable choice for construction projects in extreme weather conditions.

- Q: How do steel channels contribute to the overall functionality of a building?

- Steel channels contribute to the overall functionality of a building in several ways. Firstly, they provide structural support and stability by acting as load-bearing members. Steel channels are designed to distribute the weight and forces throughout the building, ensuring that it can withstand various loads, such as dead loads (the weight of the building itself) and live loads (people, furniture, equipment). Additionally, steel channels are often used in framing systems for walls, roofs, and floors. They help create a rigid framework that supports the building envelope, allowing for the construction of open and flexible spaces. Steel channels also play a crucial role in creating partitions and dividing spaces within the building, providing a framework for walls and other structural elements. Furthermore, steel channels are highly durable and resistant to various environmental factors such as fire, moisture, and pests. This durability ensures the long-term integrity of the building, minimizing maintenance requirements and increasing its lifespan. In terms of functionality, steel channels also contribute to the overall efficiency of a building. They can be prefabricated, allowing for faster and more efficient construction. The dimensional accuracy and uniformity of steel channels make them easier to work with, ensuring precise assembly and reducing construction errors. Moreover, steel channels can accommodate other building systems and components, such as electrical wiring, plumbing, and HVAC systems. They provide a convenient pathway for these utilities, allowing for efficient installation and maintenance. In summary, steel channels are essential components that contribute to the overall functionality of a building. They provide structural support, stability, and durability, while also facilitating efficient construction and integration of other building systems.

- Q: Are steel channels suitable for railway infrastructure projects?

- Yes, steel channels are suitable for railway infrastructure projects. They offer excellent strength, durability, and load-bearing capacity, making them ideal for constructing railway tracks, bridges, and other related structures. Steel channels also possess corrosion resistance and can withstand heavy traffic and varying weather conditions, making them a reliable choice for long-lasting railway infrastructure.

- Q: How do steel channels contribute to the overall sustainability of a project?

- Steel channels contribute to the overall sustainability of a project in several ways. Firstly, steel is a highly durable and long-lasting material, which means that steel channels can withstand the test of time and require minimal maintenance or replacement. This reduces the overall resource consumption and waste generation associated with a project. Additionally, steel channels are recyclable, meaning that they can be melted down and reused at the end of their lifespan. This helps to reduce the demand for raw materials and the energy required for manufacturing new steel products, thus decreasing the environmental impact of a project. Furthermore, steel channels are lightweight yet strong, allowing for efficient design and construction. This leads to reduced material usage and transportation costs, as well as decreased energy consumption during the construction phase. This aspect of steel channels contributes to the overall sustainability of a project by minimizing the carbon footprint and resource depletion associated with the construction process. Moreover, steel is a non-combustible material, making it a safe choice for projects in terms of fire resistance. This enhances the overall safety and resilience of the project, reducing the risk of damage or destruction and minimizing the need for repairs or reconstruction. Lastly, steel channels offer versatility in design and construction, allowing for innovative and efficient solutions. This flexibility enables architects and engineers to optimize the use of materials, space, and energy, resulting in sustainable and eco-friendly designs. In summary, steel channels contribute to the overall sustainability of a project through their durability, recyclability, lightweight yet strong properties, fire resistance, and design versatility. By choosing steel channels, project developers can minimize resource consumption, waste generation, carbon emissions, and overall environmental impact, making their project more sustainable in the long term.

- Q: Can steel channels be used in cold storage facilities?

- Yes, steel channels can be used in cold storage facilities. Steel is a strong and durable material that can withstand the low temperatures and provide structural support for the storage facility. It is commonly used in the construction of cold storage buildings due to its resistance to corrosion and ability to maintain stability in cold environments.

- Q: Are steel channels suitable for use in the construction of balconies or terraces?

- Yes, steel channels are suitable for use in the construction of balconies or terraces. Steel channels provide excellent strength and durability, making them a reliable choice for supporting the weight of the balcony or terrace structure. They have high load-bearing capacity and can withstand heavy loads, ensuring the safety and stability of the structure. Additionally, steel channels are resistant to weathering and corrosion, which is crucial for outdoor applications like balconies and terraces. They can withstand exposure to moisture, rain, and sunlight without deteriorating or losing their structural integrity. Furthermore, steel channels offer design flexibility, allowing for various architectural styles and configurations. They can be easily fabricated and installed, making the construction process efficient and cost-effective. Overall, steel channels are a suitable and popular choice for constructing balconies and terraces due to their strength, durability, weather resistance, and design versatility.

- Q: What are the different types of connections used with steel channels?

- There are several types of connections that can be used with steel channels, depending on the specific application and structural requirements. Some of the commonly used connections include: 1. Welded connections: Welding is a popular method for connecting steel channels. It involves joining the channels by melting the adjacent edges and allowing them to solidify, creating a strong and durable connection. Welded connections can be full penetration, where the entire thickness of the channel is welded, or partial penetration, where only a portion of the thickness is welded. 2. Bolted connections: Bolted connections involve using bolts and nuts to connect steel channels. Holes are drilled in the channels, and bolts are inserted through these holes, with nuts tightened to hold the channels together. Bolted connections offer flexibility and ease of assembly and disassembly, making them suitable for situations where frequent maintenance or modifications are required. 3. Mechanical connections: Mechanical connections utilize specialized connectors, such as couplings, brackets, or plates, to join steel channels. These connectors are designed to provide a secure and reliable connection without the need for welding or bolting. Mechanical connections are often used in applications where quick installation or alignment adjustments are necessary. 4. Riveted connections: Riveting involves using rivets, which are metal pins with a formed head on one end, to connect steel channels. The rivets are inserted through pre-drilled holes in the channels and then hammered or riveted into place, securing the connection. Riveted connections were widely used in the past but have become less common due to the availability of more efficient connection methods. 5. Adhesive connections: Adhesive connections involve using high-strength adhesives to bond steel channels together. The adhesive is applied to the contact surfaces of the channels, and pressure is applied to ensure a strong bond. Adhesive connections are useful in situations where welding or bolting is not feasible, such as joining dissimilar metals or materials with high thermal expansion coefficients. Each type of connection has its advantages and limitations, and the choice depends on factors such as load requirements, design considerations, and project specifications. It is essential to consult with a structural engineer or professional fabricator to determine the most appropriate type of connection for a given steel channel application.

Send your message to us

C Channel Steel (Height: 50–400mm)

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 42000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords