Butterfly Valves Ductile Iron Wafer Type DN500

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 80000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

1. Small in size and light in weight, easy instillation and maintenance. It can be mounted wherever needed

2. Simple and compact construction, quick 90 degrees on-off operation

3. Minimized operating torque, energy saving

4. Flow curve teeing to straight line, excellent regulation performance

5. Long service life, standing the test of tens of thousands opening/closing operations

6. Bubbles-tight sealing with no leakage under the pressure test

7. Wide selection of materials, applicable to various mediums

8.Simple and compact construction. Small in size and light in weight. Easy transportation, installation and maintenance.

9. Quick 90 degrees on-off operation. Minimized operating torque ,energy saving.

10. Excellent sealing performance with no leakage. Long service life.

11. Wide selection of materials ,applicable for various media..

12. Flow curve tending to straight line. Excellent regulation performance.

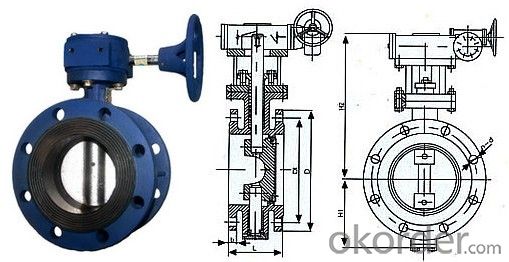

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: D37A1X9-16CB1: what does this butterfly valve mean?

- The model is composed of 7 units, the types of valves (gate valve Z, J, L, Q ball valve, throttle valve, check valve and H valve, butterfly valve, connection mode (D) internal thread 1 thread 2, welding flange 4, 6, 7, the clamp (0) electromagnetic transmission mode 1 solenoid valve, hydraulic, electric and hydraulic turbine are 2, 3, 4 and 5 gears, bevel gear, pneumatic hydraulic, 6, 7, 8, 9) pneumatic and hydraulic, electric, structure (straight or DC type 7,1 on behalf of the center plate, vertical type A (A) and LT X9) on behalf of a sealant is heat-resistant rubber, kg 16 kg, C represents the body material of carbon steel WCB, B1 on behalf of the valve plate is made of ductile cast iron plating)

- Q: I am confused as to the answer of this question. Please help.Indicate the status of the mitral, tricuspid and semilunar valves (whether they are open or closd) during the various phases of the cardiac cycle. Discuss the pressure in each of the relevant chambers or blood vessels during the phases with reference to the opening or closing of the valves.

- A heartbeat is a two-part pumping action that takes about a second. As blood collects in the upper chambers (the right and left atria), the heart's natural pacemaker (the SA node) sends out an electrical signal that causes the atria to contract. This contraction pushes blood through the tricuspid and mitral valves into the resting lower chambers (the right and left ventricles). This part of the two-part pumping phase (the longer of the two) is called diastole. The second part of the pumping phase begins when the ventricles are full of blood. The electrical signals from the SA node travel along a pathway of cells to the ventricles, causing them to contract. This is called systole. As the tricuspid and mitral valves shut tight to prevent a back flow of blood, the pulmonary and aortic valves are pushed open. While blood is pushed from the right ventricle into the lungs to pick up oxygen, oxygen-rich blood flows from the left ventricle to the heart and other parts of the body. After blood moves into the pulmonary artery and the aorta, the ventricles relax, and the pulmonary and aortic valves close. The lower pressure in the ventricles causes the tricuspid and mitral valves to open, and the cycle begins again. This series of contractions is repeated over and over again, increasing during times of exertion and decreasing while you are at rest. The heart normally beats about 60 to 80 times a minute when you are at rest, but this can vary. As you get older, your resting heart rate rises. Also, it is usually lower in people who are physically fit.

- Q: What are the advantages of butterfly valves?

- D. sediments are not readily accumulated;The E. is compact and has little installation

- Q: Seat has said to the previous owner that the car needs a new air mass meter and dump valve.I am putting a new air mass meter on it.Does it have a dump valve.I know very little on this subject.

- every turbo will have a dump valve(waste gate) to regulate the boost to the engine Dump valves are fitted to the engines of turbo charged cars and sit between the turbo outlet and the throttle body. When transitioning from a boosted state to a closed throttle state (as in between shifts), due to inertia, the turbo continues to pressurize air, but the closed throttle prevents the compressed air from entering the engine. In this case the pressure exceeds the preset spring pressure in the dump valve and the excess pressure is bled off to atmosphere. Even with a dump valve the compressed air acts as a brake on the turbo (slowing it down), because the pressure on the backside of the turbo is at a higher pressure than on the front side (and the air actually wants to flow through the turbo backwards). A blowoff valve is a more elegant solution to this problem by allowing the turbo to freewheel when the throttle is closed (equalizing the pressure on both sides of the turbo). Unlike a dump valve a blowoff valve can be used at multiple boost settings without reconfiguration. Blowoff valves are sometimes incorrectly called dump valves because they serve a similar function, but they are very different solutions to the same problem.

- Q: I went online to check where was the pcv valve for a 2001 ford focus, but I didn't find it. Does anyone have a picture? Thanks

- Its on the front of a line that looks like a big black t and it is very hard to notice.

- Q: What does butterfly valve do?

- Butterfly valve (English: butterfly valve) refers to the closure of parts (valve or butterfly plate) for the disk, around the valve shaft to achieve rotation and closure of a valve, the main cut off on the pipe and throttling. Butterfly valve headstock is a disc shaped disc, in the valve body around its own axis of rotation, so as to achieve the purpose of opening or closing or regulation. Butterfly valve is fully open to fully closed is usually less than 90 degrees, butterfly and butterfly stroke itself has no self-locking capability, in order to position the disc to install the valve stem on the worm gear. Using worm gear reducer, not only can the butterfly plate have self-locking ability, so that the butterfly board stops at any position, but also can improve the operation performance of the valve. Industrial butterfly valve features, capable of high temperature, applicable pressure range is higher, the valve nominal diameter is large, the valve made of carbon steel, the valve plate sealing ring using metal rings instead of rubber rings. Large high temperature butterfly valve welded by steel plate, mainly used for high temperature smoke duct and gas pipe.

- Q: What is the meaning of American Standard butterfly valve B series

- American Standard flange connection is divided into A, B series. A series for normal flanges, B series for compact flanges. 24 "to no AB series, flange standards for B16.5, 24" above B16.47.

- Q: That industry uses most of the butterfly valve, and only use the butterfly valve, a large number of use of butterfly valve, seek expert advice!

- I know there are automatic fire fighting systems and the oil industry.

- Q: The difference between the directly buried gate and the flange valve and butterfly valve

- Buried gate also called buried gate valve, valve can be directly buried underground, built without manhole, reduce road excavation area; small well maintained road and beautiful room can reduce the difficulty of construction, reduce project cost. The directly buried soft sealing gate valve is divided into two types: telescopic type and fine fixing type, wherein, the telescopic type is divided into metal type and plastic type. In the process of construction, the telescopic type can be adjusted arbitrarily according to the distance between the buried depth of the valve and the ground, and the micro adjustment can be adjusted on the spot. The directly buried gate valve has the advantages of long-term use, no leakage, no maintenance, etc., and can effectively avoid other people switching the valve and stealing the manhole cover at will.Flange gate valve is connected to the flange gate valve, this connection is the most common way.

- Q: What is the difference between wafer (flangeless) type and LUG type of butterfly valves?

- WAFER butterfly valve is the valve is divided into LUG (ears) with and without LUG, ordinary LUG without clip on 12 points in the direction of valve is generally two to four bolt holes was not, whereas the LUG of butterfly valve cross dispersed in a circle. Bolt hole. With LUG all bolted through the LUG, so that the butterfly valve and the clamp on the two flange connection is more solid, you check the valve picture, it is easy to understand

Send your message to us

Butterfly Valves Ductile Iron Wafer Type DN500

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 80000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords