Butterfly Valve with Plastic Handle Made in China on Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow.

The closing mechanism takes the form of a disk.

Operation is similar to that of a ball valve, which allows for quick shut off.

Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required.

The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve.

Rotating the actuator turns the disc either parallel or perpendicular to the flow.

Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a) Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b) Soft seat. Replaceable. Increase of service life.

c) Double half shaft without pin.

d) Square and short neck.

e) Easy to stick scutcheon and cost saving.

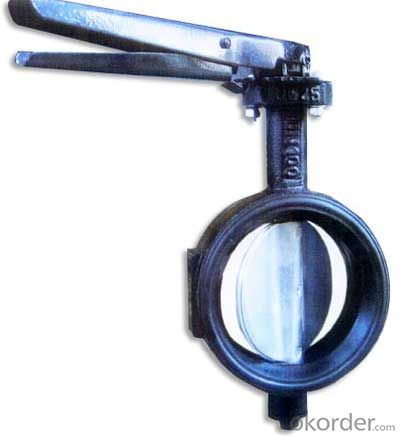

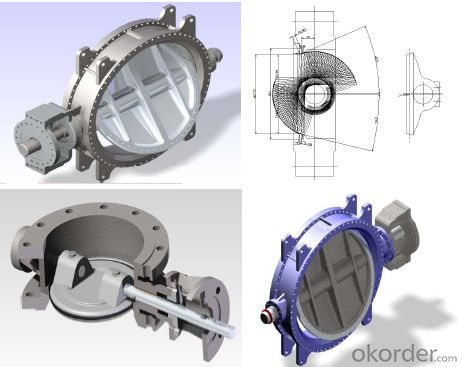

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1) What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2) How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

- Q: Where is the Shandong valve? How about joint valves in Shandong?

- To find Shandong valve manufacturers, Shandong better valve manufacturers are in Weifang, find the valve factory is also simple, direct search "Weifang valve" is

- Q: What do the Z, J, H and D represent in the valve type?

- 7, pairs of clipsThe transmission modes of valves are code 9, 6 and 3 respectively:9, electric, 6, pneumatic, 3, turbo wormBody material code Z, K, Q, T, C, P, R, V, respectively:Grey cast iron, malleable cast iron, ductile iron, copper and alloy, carbon steel, stainless steel, chrome nickel chromium nickel molybdenum stainless steel, chromium molybdenum vanadium steelSeat seal or lining code R, T, X, S, N, F, H, Y, J, M, W, respectively

- Q: What's the valve specification DN20?

- It's not clear what you want to ask

- Q: I would like to ask how the valve entry, for a new pair, really difficult, what cutaway view, there are other, just contact the valve less than a week, and sometimes it is really difficult to understand. Forget the experienced teacher can be generous with your criticism to later, indebted forever, learn the valve Comrades some help.In a company CAD to relatives as soon as possible to a company, and then slowly improve, I do not know what is the request of the novice, and how to start as soon as possible, I am learning routine is: give me a set of valve design drawings, and then I paint it on, do not understand the structure and workshop look. I wonder if you have any good learning methods that can be referred to and supplemented by younger brother

- May learn some basic knowledge of valves, learning in practice, relatively fast.

- Q: What does 3/4''mean in the name of the valve?

- Valve diameter, that is, we often say 6 points valve, used in English units, with metric units should be DN20.2 points DN84 points DN156 points DN20 (3/4'')1 inches DN251.2 'DN321.5 'DN402 'DN502.5 'DN653 'DN804 'DN1005 'DN1256 'DN1508 'DN20010 'DN25012 'DN300Nominal diameter (nominal, diameter), also known as the average diameter (mean, outside, diameter).The tube is thin from the metal tube, and the outer diameter of the tube is almost the same as the inner diameter of the tube, so the average value of the outer diameter of the tube and the inner diameter of the pipe is called the diameter.Because the units have metric (mm) and British (inch) distinction, there are the following methods of address.1., based on the metric system (mm), called DN (metric unit)2., on the basis of the British system (inch), called NB (inch unit)DN (nominal, diameter)NB (nominal, bore)OD (outside, diameter)

- Q: How can you replace the other valve when the main valve is not closed and no water is stopped?

- In general, a unit has a total valve. From this start, find it, find a less water when passing the total valve home to change, more energy, save trouble later. Or find the person of the company to deal with tap water.

- Q: The customer sent an inquiry sheet, in which check valve DE50, balance valve DE25, stop valve DE75, and I want to know what de stands for, because the price of plastic and cast iron is different. What does de usually mean in the industry?

- No, DE is DG, and DG stands for nominal diameter of valve

- Q: HH valve company in the United Kingdom, how about the valve?

- Our factory boiler has this brand of valve, used for many years, has been no problem, really good.

- Q: What's the name of the valve?

- This is not a valve, it is a pipe bender.

- Q: Where is it installed, what is the role, what is the material, and are there other alternatives instead of this effect?

- Main stem to prevent leakage, there are PTFE and graphite and so on. There are no other good products to replace.

Send your message to us

Butterfly Valve with Plastic Handle Made in China on Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches