Valve with Best Price from 50year Old Valve Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

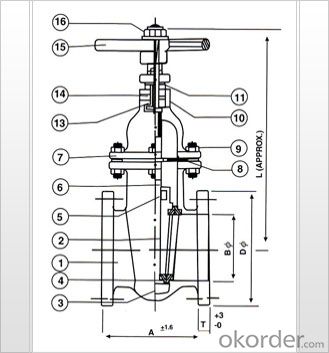

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q: Why is copper used in cryogenic valves?

- Copper, which is rarely available, is easily deformed at low temperatures and is much more WCB or WCC.Below -46 degrees C, SA352, LCB.LCC

- Q: How do you calculate the valve wall thickness, pressure, and other valve design calculations in a spreadsheet?

- For you to introduce the spreadsheet calculation, application basis, you according to this principle for valve correlation calculation:When A1 and B1 cells are used as parameters, the amount of computation is calculated by C1. If the formula is X+Y=? In the A1 cell, fill in the X; fill the Y in the B1 cell; fill in the C1 cell with "=A1+B1"; enter the carriage, and then calculate the corresponding value in the C1 cell. For example: fill in 5 in the A1 cell; fill in 8 in the B1 cell; enter the carriage, and then appear in the C1 cell 13. Other calculations are the same, you will calculate the valve formula, such as the above fill in, given the corresponding parameters, the same can be calculated.

- Q: The expert can tell me how to install this valve, and what fittings to use on both sides

- On the first floor, the two floor adds up to the perfect answer: look at the flow direction and weld it directly to the pipeIf the process permits, you can first weld on both sides of the flange, modified into a flange butterfly valve, and then installed on the pipe, easy to overhaul later

- Q: I'm going to put a solar energy and an electric water heater installed in the same hot water pipe, a valve, a valve open and close the valve B and vice versa the installation of solar and electric water heater, there can be no linkage valve?

- In industry, you say this, such as using two butterfly linkage and composition of the three-way valve to use. But civilian should be few, demand is very little ah. It is estimated that you can only install two valves and then use both hands at the same time to perform linkage.

- Q: The general signal valve installation, or other valve installation is not installed with the groove flange clamp hoop Yucca or direct way? What's the convenient way to install the following diagram? I don't understand. Neither groove, flange nor hoop. Thank you, sir!

- For clip type, the two flanges on the pipe are drawn with studs, and the middle is the butterfly valve

- Q: What do you mean by the 16 bit coding of the valve type?

- Not regular encoding. Regular encoding is usually 11 bit and sometimes 13-14 bit

- Q: What is the purpose of the valve?

- Valve is a pipe accessory. It is a device used to change the direction of the passage and the direction of the medium flow, and to control the flow of the conveying medium.Valves have the following uses:1. Connect or cut off the medium in the pipe. Such as gate valve, globe valve, ball valve, plug valve, diaphragm valve, butterfly valve and so on.2 、 adjust and control the flow and pressure of the medium in the pipeline. Such as throttle, control valve, pressure reducing valve, safety valve, etc..

- Q: How much is the 150LB of the valve?

- 150Lb=2.0MPa=20 kg.Valve (Famen) is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure.Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications.

- Q: How does the valve rust die?

- The treatment of valve rust is as follows:1, use corner grinder cut off valve, and then a small mill grinding wheel cutting residual film cut pipe installed in the screw part, when the attention of cutting depth.2, with the amount of hydrochloric acid corrosion and rust of the valve, until the rust completely removed, rinse with water.3, on the newly purchased valve galvanized, can effectively prevent rust.Valve (Famen) is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure. Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications. Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow.

- Q: Yongde jiekelong valves and valves of the good faith

- Fujian Xiamen huashenghong Sanitary drainage fittings. Furniture guide rail, hardware, Taiwan locomotive. All of the above are the strongest domestic brands, high quality, stable performance, durable, buy a lifetime warranty, quality products. Domestic airport, water cube, bird's nest are using the above brand accessories.

Send your message to us

Valve with Best Price from 50year Old Valve Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords