Building Hoist SCD320 with Counterweight

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Building Hoist Description

Feature: Building Hoist Condition: New Application: Construction

Payload(kg):3200 Lifting Speed(m/min):0~60 Motor Power(kw): 3*15

Safety Device: SAJ50-1.4 Cage: Single Counterweight: Yes

Certification: CE,ISO Place of Origin: China(Mainland) Model Number: Type:SCD320

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package Delivery Detail: 25-30days

Main Parts of Building Hoist

● Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

● Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process,

and ensures automated leveling.

● Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

● The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

● The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake

and prolongs the spare parts'life.

● The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling protection functions,

● The system applies the special software for hoists developed by our company, making the operation more safe and

reliable.

Building Hoist Images

CMAX Building Hoist

Anchorage System

Mast Section

Driving Unit

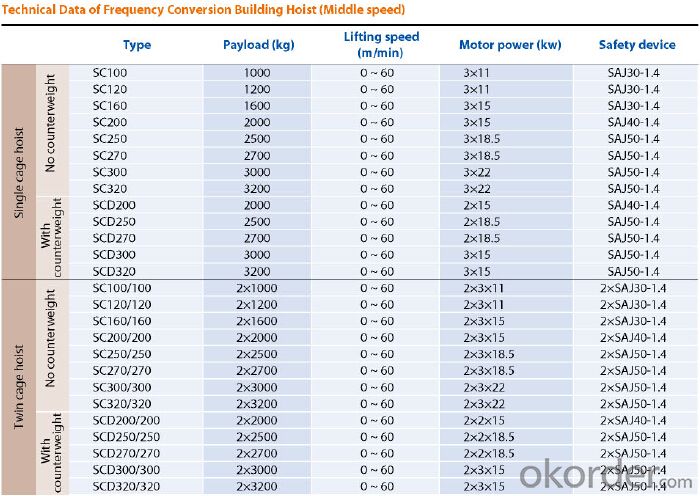

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance

& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: This question asks about the criteria for determining when a building hoist has reached the end of its useful life and should be replaced.

- <p>The lifespan of a building hoist is determined by several factors including its design, materials, usage, maintenance, and compliance with safety standards. Regular inspections and maintenance are crucial to assess the hoist's condition. A hoist should be replaced when it shows significant wear, has been in service beyond the manufacturer's recommended lifespan, or fails to meet safety standards. Additionally, any hoist that has been involved in an accident or has undergone major repairs may need to be replaced to ensure safety. Consulting the manufacturer's guidelines and local regulations can provide specific information on when a hoist should be retired.</p>

- Q: This question asks about the various elements that can influence the efficiency and effectiveness of a building hoist.

- <p>The performance of a building hoist is affected by several factors including the type and weight of materials being lifted, the frequency of use, the hoist's mechanical condition and maintenance, environmental conditions such as wind and temperature, the skill and training of operators, and the design and capacity of the hoist itself. Proper installation, regular inspections, and adherence to safety protocols also play a crucial role in ensuring optimal performance and safety. Additionally, the quality of electrical systems, the efficiency of the drive mechanism, and the structural integrity of the hoist's components can significantly impact its operation.</p>

- Q: Are there any good signs in the construction elevator door

- Referring to the unified code of construction safety technology of GB 50870-2013, and the construction safety inspection standard JGJ59-2011

- Q: How many floors are built to use the construction elevator? With six floors?

- No ~ there is no hard and fast rule, you need to choose from the construction, main consideration cost

- Q: What are alternative uses for a building hoist besides construction?

- <p>Yes, a building hoist can be used for purposes other than construction. It can be utilized for moving heavy equipment in industrial settings, transporting goods in warehouses, or even in emergency services for rescue operations. Its ability to lift and lower heavy loads makes it versatile for various applications where vertical transportation is required. However, it's crucial to ensure that any alternative use complies with safety regulations and the hoist's operational specifications.</p>

- Q: This question asks for the distinctions between two types of building hoists: manual and automatic.

- <p>Manual building hoists require human effort to operate, typically involving a pulley system and manual controls. They are generally less expensive but slower and more labor-intensive. Automatic building hoists, on the other hand, are motorized and can be programmed to lift and lower loads with minimal human intervention. They offer greater efficiency, speed, and safety, but come at a higher cost. Automatic hoists are also more suitable for high-rise construction due to their ability to handle heavier loads and operate over greater distances.</p>

- Q: Is it possible to utilize building hoists for the transportation of materials and equipment within construction sites?

- <p>Yes, building hoists are commonly used in construction sites to move materials and equipment. They are designed to lift and lower heavy loads vertically, making them ideal for transporting construction materials, tools, and equipment between different floors or levels of a building under construction. This equipment significantly enhances efficiency and safety on construction sites by reducing manual labor and the risk of accidents associated with manual handling of heavy items.</p>

- Q: Is it possible to replace an electric motor with a hydraulic cylinder in an electric-hydraulic lifting system?

- <p>No, a hydraulic cylinder cannot be used in place of a motor in an electric-hydraulic lifting system. A hydraulic cylinder is a component that converts hydraulic pressure into linear motion, while an electric motor converts electrical energy into mechanical energy. In an electric-hydraulic system, the motor drives a hydraulic pump, which generates the pressure needed to actuate the cylinder. The motor is essential for providing the power source, and the cylinder is the actuator that uses this power to perform work. Replacing the motor with a cylinder would result in a system without a power source, rendering it inoperative.</p>

- Q: Helped wall bar how to set up, and several layers of set a, two width, wall rod need a few meters long, what shape is the embedded parts, how much of a steel bar, Angle and wall vertical or have?

- According to drawings, find the embedded at the scene near the level of architectural axis positioning and high elevation line (50 wire or 1 m wire) location and double-check, axis dividing levels as much as possible in accordance with the size distribution. Find out after each axis, measuring building contour, and map measure the buildings, and building construction drawing contrast, timely transfer measurement results to the designer, designer analyze the error and make changes

- Q: Is it possible to utilize a building hoist for elevating construction materials at construction sites?

- <p>Yes, building hoists are commonly used for lifting materials at construction sites. They are designed to transport heavy construction materials and personnel vertically, which is essential for multi-story construction projects. These hoists are equipped with safety features and are operated by trained personnel to ensure the secure and efficient movement of materials and workers.</p>

Send your message to us

Building Hoist SCD320 with Counterweight

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords