Building Hoist with CE Approved Construction SC200

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

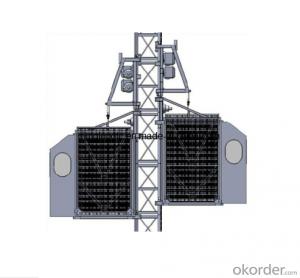

Building Hoist with CE Approved Construction SC200

We are special supplier of building hoist in China, our building hoist have been Widely exported to all over the world and won good reputation, whose payload capacity is as much as 10000kg, lifting speed can reach up to 96m/min, and the erection height reaches up to 550m., our products have been widely used for transportation for both men and cargo in field of general buildings, but also industry, electric power, mining well, oil, chemical industry etc.

SC270TD, SC270/270TD building hoist:

1). Each cage load capacity: 2700kg

2). Lifting speed: 36m/min, or 0∼ 63m/min, or 0∼ 96m/min

3). Mast section: Paint or hot dipping zinc

4). Cage: Single cage or twin cage

5). Recommended cage inner dimension(LxWxH)(m): 2.5x1.3 x2.5; 3.0x1.3x2.5; 3.2x1.5x2.5; 3.6x1.5x2.5; 3.8x1.5x2.5; 4.0x1.5x2.5; 4.2x1.5x2.5, cage dimension is according to requirement of customer and special project.

6). Motor and reducing device: Made in China, can be SEW Germany according to requirements.

7). Counterweight: With counterweight or without counterweight

8). The colors of cage: Yellow, or red, or blue

9). Other each cage load capacity for your to choose: 1000kg, 2000kg, 2700kg, or 3200kg

| Type | Payload kg | Lifting speed m/min | Motor power kW | Inverter power kW | Counter Weight kg | ||

| Low speed | Single cage no counterweight | SC200GD | 2000 | 0~46 | 3×15 | 45 | 0 |

| SC270GD | 2700 | 0~46 | 3×18.5 | 55 | 0 | ||

| SC320GD | 3200 | 0~46 | 3×22 | 75 | 0 | ||

| Twin cage no counterweight | SC200/200GD | 2×2000 | 0~46 | 2×3×15 | 2×45 | 0 | |

| SC270/270GD | 2×2700 | 0~46 | 2×3×18.5 | 2×55 | 0 | ||

| SC320/320GD | 2×3200 | 0~46 | 2×3×22 | 2×75 | 0 | ||

| Middle speed | Single cage no counterweight | SC120GZ | 1200 | 0~63 | 3×15 | 45 | 0 |

| SC200GZ | 2000 | 0~63 | 3×18.5 | 55 | 0 | ||

| Single cage with counterweight | SCD200GZ | 2000 | 0~63 | 2×15 | 30 | 2000 | |

| SCD270GZ | 2700 | 0~63 | 2×18.5 | 37 | 2000 | ||

| SCD320GZ | 3200 | 0~63 | 3×15 | 45 | 2000 | ||

| Twin cage no counterweight | SC120/120GZ | 2×1200 | 0~63 | 2×3×15 | 2×45 | 0 | |

| SC200/200GZ | 2×2000 | 0~63 | 2×3×18.5 | 2×55 | 0 | ||

| Twin cage with counterweight | SCD200/200GZ | 2×2000 | 0~63 | 2×15 | 2×30 | 2×2000 | |

| SCD270/270GZ | 2×2700 | 0~63 | 2×18.5 | 2×37 | 2×2000 | ||

| SCD320/320GZ | 2×3200 | 0~63 | 2×3×15 | 2×45 | 2×2000 | ||

| High speed | Single cage no counterweight | SC100GS | 1000 | 0~96 | 3×22 | 75 | 0 |

| SC120GS | 1200 | 0~96 | 3×22 | 75 | 0 | ||

| SC200G | 2000 | 0~96 | 3×22 | 90 | 0 | ||

| SC200GS | 2000 | 0~96 | 3×22 | 90 | 0 | ||

| Single cage with counterweight | SCD200G | 2000 | 0~96 | 3×15 | 45 | 2000 | |

| SCD200GS | 2000 | 0~96 | 2×22 | 45 | 2000 | ||

| SCD270G | 2700 | 0~96 | 3×18.5 | 55 | 2000 | ||

| SCD320GS | 3200 | 0~96 | 3×22 | 75 | 2000 | ||

| Twin cage no counterweight | SC100/100GS | 2×1000 | 0~96 | 2×3×22 | 2×75 | 0 | |

| SC120/120GS/ | 2×1200 | 0~96 | 2×3×22 | 2×75 | 0 | ||

| SC200/200G | 2×2000 | 0~96 | 2×3×22 | 2×90 | 0 | ||

| SC200/200GS | 2×2000 | 0~96 | 2×3×22 | 2×90 | 0 | ||

| Twin cage with counterweight | SCD200/200G | 2×2000 | 0~96 | 2×3×15 | 2×45 | 2×2000 | |

| SCD200/200GS | 2×2000 | 0~96 | 2×2×22 | 2×45 | 2×2000 | ||

| SCD270/270G | 2×2700 | 0~96 | 2×3×18.5 | 2×55 | 2×2000 | ||

| SCD320/320G | 2×3200 | 0~96 | 2×3×22 | 2×75 | 2×2000 | ||

| SCD320/320GS | 2×3200 | 0~96 | 2×3×22 | 2×75 | 2×2000 | ||

- Q: Is it possible to use a manual building hoist to lift multiple objects simultaneously?

- <p>Yes, a manual building hoist can be used to lift multiple objects at once, provided the total weight does not exceed the hoist's maximum load capacity. It's crucial to ensure that the hoist is securely attached to a stable structure and that all safety protocols are followed to prevent accidents. The objects should be evenly distributed and properly secured to the hoist to maintain balance and prevent tipping. Always refer to the manufacturer's guidelines for specific weight limits and safety instructions.</p>

- Q: This question asks if a building hoist can be utilized to lift various types of materials including wood, steel, and concrete.

- <p>Yes, building hoists are designed to lift a variety of materials. They are commonly used in construction to transport materials such as wood, steel, and concrete between different floors. However, it's important to ensure that the hoist is appropriately rated for the weight of the materials being lifted and that safety protocols are followed. Each material may require specific handling techniques or attachments to secure the load properly and prevent damage or accidents.</p>

- Q: This question asks about the typical issues encountered with building hoists and the methods to address these problems.

- <p>Common faults in building hoists include mechanical failures such as worn gears or chains, electrical issues like short circuits or malfunctioning controls, and structural problems such as misaligned guides or damaged safety devices. To deal with these issues, regular maintenance and inspection are crucial. Mechanical faults can often be resolved by replacing worn parts or lubricating moving components. Electrical problems may require a thorough check of wiring and control systems, possibly involving a qualified electrician. Structural issues might necessitate adjustments or repairs to ensure the hoist operates safely. In all cases, following the manufacturer's guidelines and safety protocols is essential to prevent accidents and ensure the hoist's reliable operation.</p>

- Q: This question asks for safety guidelines and procedures to be followed when operating a building hoist.

- <p>To use a building hoist safely, follow these guidelines: Ensure the hoist is regularly inspected and maintained by qualified personnel. Never exceed the hoist's load capacity. Keep the hoist and its surroundings clean and free from debris. Always use safety hooks and never leave the hoist unattended when in use. Ensure all safety features, such as limit switches and emergency stop buttons, are functioning correctly. Train operators on the proper use of the hoist and adhere to all manufacturer's instructions. Never use a hoist if it shows signs of damage or malfunction. Always wear appropriate personal protective equipment (PPE) when operating a hoist.</p>

- Q: What is the height of protecting door protection of construction elevator

- Elevator protection door is strict according to the mandatory standard to set up elevator well protection measures for safety technology. The shaft must be set in the range of 1.5 to 1.8, with protective railings or fixed gate and protective railings or fixed doors. 2, elevator well in plus or minus zero layer need to set up the first safety net, every two layers, the upper part of most every 10 m AnQuanPing network design, network security quality must gb5725-1997 "safety net" of standard network, methods must be checked in accordance with the relevant provisions. Installation in the safety net elevator dismantlement, the operator should wear the seat belt according to the regulation. On the floor and roof, a short side hole is larger than 1.5 m, the hole should be set in the requirement of the protective railing, the bottom setting safety net. To set safety warning signs that meet national standards in the elevator shaft. Safety warning signs are clear, warning lights should be set at night. The protective railings and gates shall be marked with yellow and black stripes and shall be manufactured according to the standards of construction safety technical specifications. 5, elevator wellhead protection facilities need to dismantle or change temporarily, and by the project full-time safety sign shall be the responsibility of the project director, and ready to move or change the security countermeasures. To inform all staff at the same time; Recovery after safety facilities must be by the project director, full-time security personnel and other related personnel on-site inspection management, qualified rear can continue to use.

- Q: What specific regulations or conditions must be met when utilizing lifting equipment in construction or factory environments?

- <p>Yes, there are special requirements for using lifting equipment in construction sites and factories. These include adherence to safety regulations, regular maintenance and inspection, proper operator training, and ensuring the equipment is suitable for the task. Compliance with local and national laws such as OSHA in the U.S. or CE marking in the EU is crucial. Equipment must be certified safe for use, and operators must be licensed and follow safety protocols. Additionally, load capacities must be respected, and lifting operations must be planned and supervised to prevent accidents.</p>

- Q: What are the essential maintenance tasks and checks required to keep a hydraulic building hoist in good working condition?

- <p>Regular maintenance of a hydraulic building hoist is crucial for safety and efficiency. Key requirements include inspecting and lubricating moving parts, checking for leaks in hydraulic lines and seals, ensuring the hoist's load limit is not exceeded, and verifying the operation of safety devices like limit switches and emergency stops. Additionally, the hydraulic fluid should be checked for contamination and changed as needed, typically every 1000 hours of operation or annually. The electrical system should be inspected for any damage or wear, and all controls should be tested for proper functionality. A thorough inspection by a qualified technician is recommended at least once a year to ensure all components are in compliance with safety standards.</p>

- Q: This question asks for the detailed specifications and dimensions of a building hoist, which is a type of construction equipment used to lift materials.

- <p>The specifications and measurements of a building hoist can vary significantly depending on the model and manufacturer. Generally, a building hoist (also known as a construction hoist or material hoist) is characterized by its load capacity, which can range from 500 kg to several tons. The height of the hoist is determined by the number of floors it serves, typically measured in meters. The width and depth are usually around 1.5 to 2 meters, and the speed can vary from 24 to 60 meters per minute. The power requirement is often between 3 to 7.5 kW. Safety features like overload protection, emergency stop, and limit switches are also standard. For precise specifications, it's essential to consult the manufacturer's data sheet for the specific model in question.</p>

- Q: Is it possible to utilize a building hoist for the transportation of objects?

- <p>Yes, a building hoist is specifically designed for moving objects, particularly in construction settings. It is used to lift and lower materials and equipment vertically, making it ideal for moving heavy objects between different floors of a building under construction. Building hoists are engineered to handle the weight and size of various construction materials, ensuring efficient and safe transportation.</p>

- Q: What is the purpose of a building hoist and can it be utilized for lifting heavy objects that cannot be manually lifted?

- <p>Yes, building hoists are specifically designed to lift heavy objects that are beyond the capacity of manual lifting. They are essential in construction sites for moving materials such as bricks, cement, and steel beams to various levels of a building. Building hoists are engineered to handle significant weight and ensure the safe and efficient transport of materials, reducing the risk of injury and improving productivity on construction sites.</p>

Send your message to us

Building Hoist with CE Approved Construction SC200

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords